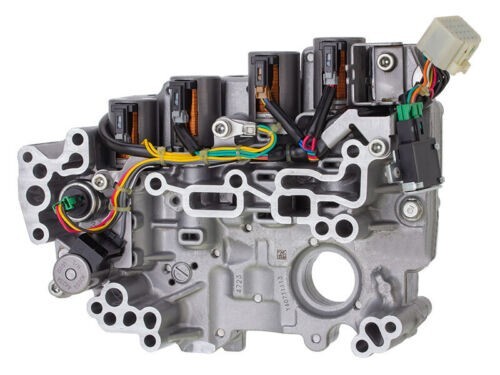

2013 Nissan Sentra Valve Body

The 2013 Nissan Sentra, a reliable and fuel-efficient compact sedan, occupies a significant space in automotive history. While its valve body, a crucial component in its transmission, might not be the first thing that springs to mind when discussing automotive innovation, examining it in the context of today's rapid advancements offers a valuable perspective. It allows us to appreciate how far we've come and to anticipate the exciting, yet challenging, road ahead for mobility.

The Valve Body: A Look Back, A Bridge Forward

The valve body in the 2013 Sentra, like those in many traditional automatic transmissions, is a marvel of mechanical engineering. It's a complex hydraulic control system, directing transmission fluid under pressure to engage different gears, allowing for smooth and efficient shifting. It's a testament to precision manufacturing and a reliance on established principles. However, its complexity also presents challenges: potential for wear and tear, susceptibility to fluid contamination, and limitations in responsiveness compared to modern electronic control systems.

Today, the automotive landscape is undergoing a seismic shift. The internal combustion engine (ICE), the heart of vehicles like the 2013 Sentra, is gradually being replaced by electric powertrains, hybrid systems, and other alternative technologies. This transition has profound implications for components like the valve body.

The Rise of Electrification and the Future of Transmissions

Electric vehicles (EVs) are rapidly gaining traction, driven by increasing environmental awareness, advancements in battery technology, and government incentives. EVs, in their purest form, don't require multi-speed transmissions in the same way as ICE vehicles. Their electric motors provide instant torque across a wide speed range, often negating the need for complex gearboxes. Some EVs utilize a single-speed reduction gear, or even a two-speed transmission for enhanced performance. This significantly simplifies the powertrain and eliminates the need for a traditional valve body. This is a paradigm shift that challenges the very foundation of transmission design.

Hybrid vehicles, on the other hand, present a more nuanced picture. While some hybrids retain traditional automatic transmissions with modified valve bodies or advanced electronic control systems, others employ continuously variable transmissions (CVTs) or innovative e-CVTs. CVTs offer seamless gear ratio changes, optimizing engine efficiency and fuel economy. E-CVTs, found in many Toyota and Lexus hybrids, utilize a power-split device that combines the output of the engine and electric motor, creating a hybrid powertrain without conventional gears. Even in hybrids that *do* use traditional transmissions, the valve bodies are far more sophisticated than those found in older vehicles like the 2013 Sentra, incorporating advanced sensors, electronic controls, and optimized hydraulic circuits for improved efficiency and responsiveness.

The Technological Tsunami: Smart Automotive Solutions

Beyond electrification, the automotive industry is being revolutionized by a wave of smart technologies. Advanced Driver-Assistance Systems (ADAS), connectivity, and autonomous driving capabilities are transforming the driving experience. These advancements are not only impacting powertrain design but also influencing the entire vehicle architecture.

Consider the implications for transmission control. In a fully autonomous vehicle, the transmission, or its electric equivalent, will be seamlessly integrated with the vehicle's overall control system. Artificial intelligence (AI) algorithms will optimize gear selection based on real-time traffic conditions, road topography, and driver preferences (or the programmed driving style). The valve body, if it exists in a future transmission design, will be a highly sophisticated mechatronic unit, controlled by advanced software and communicating with other vehicle systems through a complex network.

Challenges and Opportunities: A Realistic Perspective

While the future of mobility is undeniably exciting, it's crucial to acknowledge the challenges that lie ahead. The transition to electric vehicles requires significant investments in charging infrastructure, battery technology, and raw material sourcing. The development and deployment of autonomous driving technology raise complex ethical, legal, and societal questions. Moreover, the automotive industry must address the environmental impact of battery production and disposal to ensure that EVs are truly sustainable.

The skills gap is another critical concern. The automotive workforce needs to be retrained to work with electric powertrains, advanced sensors, and software-defined vehicles. Educational institutions and industry training programs must adapt to meet these evolving needs. Furthermore, affordability remains a barrier for many consumers. Making EVs more accessible to a wider range of buyers is essential for accelerating the transition to electric mobility. The automotive sector must innovate not only in technology but also in business models to overcome these challenges.

However, these challenges also present significant opportunities. The shift to electrification is driving innovation in battery technology, leading to longer ranges, faster charging times, and lower costs. The development of autonomous driving technology has the potential to reduce traffic accidents, improve transportation efficiency, and enhance mobility for people with disabilities. The automotive industry is becoming more sustainable, connected, and intelligent, creating new jobs and economic opportunities.

New Materials and Manufacturing Processes

The future of automotive components, including potential replacements or highly advanced versions of the valve body, will rely heavily on new materials and innovative manufacturing processes. Lighter, stronger materials like carbon fiber composites and advanced alloys will improve vehicle efficiency and performance. Additive manufacturing (3D printing) will enable the creation of complex geometries and customized components, potentially leading to more efficient and compact transmission designs. Furthermore, smart materials that can adapt to changing conditions could revolutionize transmission control systems, optimizing performance and extending component life.

Imagine a valve body, or its future equivalent, incorporating self-healing polymers that automatically repair minor wear and tear. Or consider a transmission system that uses advanced sensors and AI algorithms to predict and prevent failures, proactively scheduling maintenance before problems arise. These are not mere fantasies but realistic possibilities given the rapid pace of technological advancement.

The Future is Now: A Visionary Note

Looking ahead, the automotive industry is poised for a period of unprecedented transformation. The 2013 Nissan Sentra, with its relatively simple valve body, serves as a reminder of how far we've come. The future promises a world of electric, connected, and autonomous vehicles, powered by advanced technologies and driven by a commitment to sustainability. Mobility will become more seamless, efficient, and accessible, transforming the way we live and work.

The valve body, in its current form, may eventually become a relic of the past. However, the principles of hydraulic control, precision engineering, and optimization will continue to be relevant in the future of automotive design. The challenge lies in adapting these principles to new technologies and embracing a more holistic and integrated approach to vehicle engineering.

Ultimately, the future of mobility is not just about technology; it's about creating a better world for all. It's about reducing our carbon footprint, improving safety, and enhancing the quality of life. It's about embracing innovation and working together to build a more sustainable and equitable transportation system. The journey is just beginning, and the possibilities are endless.