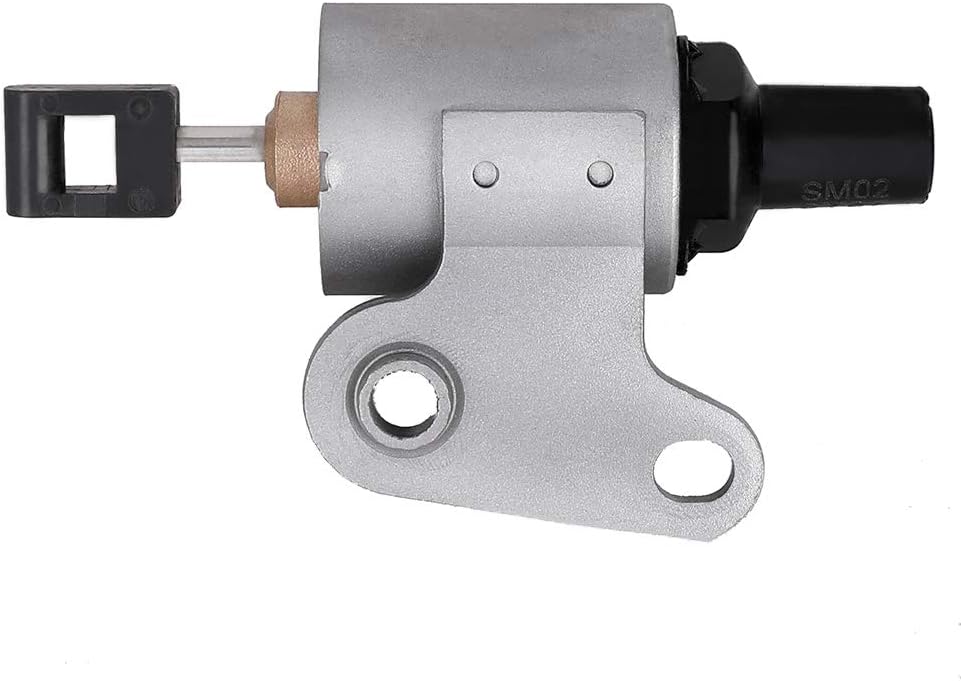

2014 Nissan Maxima Step Motor

The 2014 Nissan Maxima, a popular full-size sedan, relies on a step motor within its electronically controlled automatic transmission (ECT) system. This component, though seemingly small, plays a crucial role in regulating fluid pressure and consequently, shift quality and overall transmission performance. This article delves into the technical specifications, engineering choices, real-world performance, and reliability of the 2014 Maxima's step motor, offering insights for automotive professionals.

Technical Specifications and Functionality

The step motor in the 2014 Maxima's Continuously Variable Transmission (CVT), specifically the RE0F10A/JF011E CVT, isn't a traditional on/off solenoid. Instead, it's a precision actuator that precisely controls the position of a valve. This valve, in turn, regulates the flow of hydraulic fluid within the transmission. The powertrain control module (PCM) dictates the step motor's position based on various inputs, including engine speed, vehicle speed, throttle position, and driver demand. The goal is to optimize the transmission's ratio for fuel efficiency, performance, and smooth operation. This is achieved by controlling the hydraulic pressure acting on the pulleys and belt within the CVT.

Specifically, the step motor is a stepper motor – an electromechanical device that converts electrical pulses into discrete mechanical movements. Each pulse causes the motor to rotate a precise angular increment (the "step"). The number of steps directly corresponds to the angle the motor shaft turns. The 2014 Maxima's step motor likely utilizes a permanent magnet stepper motor configuration, offering a good balance between torque and speed. It's critical for technicians to understand that the motor's functionality hinges on precise electrical signals.

Key specifications include:

- Voltage: Typically operates on a 12V DC system.

- Step Angle: Varies depending on the specific design, influencing the resolution and precision of fluid pressure control. A smaller step angle results in finer control.

- Number of Wires: Typically 4 or 6 wires, depending on the winding configuration (unipolar or bipolar).

- Resistance: The resistance of the motor windings is a critical parameter for diagnostics. Deviations from the specified resistance indicate a potential fault.

- Operating Temperature Range: Must withstand the high temperatures generated within the transmission.

Engineering Choices and Design Considerations

Nissan's choice of a step motor for the 2014 Maxima CVT reflects a commitment to precise control over the transmission's operation. This allows for a more refined driving experience compared to simpler solenoid-based systems. The motor's ability to modulate fluid pressure incrementally enables the CVT to continuously adjust the gear ratio, optimizing for varying driving conditions. This contrasts with traditional automatic transmissions with fixed gear ratios.

Materials used in the step motor's construction are critical for durability and longevity. The rotor, stator, and bearings must withstand constant vibration and exposure to transmission fluid. High-quality alloys and coatings are employed to minimize wear and corrosion. The design also incorporates sealing mechanisms to prevent fluid intrusion into the motor's electrical components.

Real-World Performance and Comparison

In the 2014 Maxima, the step motor contributes to the CVT's ability to deliver smooth and seamless acceleration. Drivers often praise the car's responsive throttle and the absence of jarring shifts typically associated with conventional automatics. The step motor also plays a role in fuel efficiency, allowing the CVT to maintain the engine in its optimal operating range.

Comparison with Alternatives:

Alternatives to step motors in transmission control include:

- On/Off Solenoids: Simpler and less expensive, but offer limited control over fluid pressure. This results in less refined shift quality and potentially reduced fuel efficiency.

- Proportional Solenoids: Provide more granular control than on/off solenoids but are still less precise than step motors. Proportional solenoids control fluid flow based on the current applied.

- Torque Motors: Provide high torque, but are not typically used for fine positional control as they require feedback mechanisms.

Pros and Cons of Using a Step Motor:

Pros:

- Precise Control: Enables fine-tuning of fluid pressure, leading to optimal shift quality and performance.

- Smooth Operation: Contributes to the CVT's seamless acceleration and gear ratio changes.

- Fuel Efficiency: Helps maintain the engine in its optimal operating range.

Cons:

- Complexity: More complex than simpler solenoid-based systems, potentially increasing repair costs.

- Sensitivity: Susceptible to damage from contaminated transmission fluid or electrical issues.

- Cost: Typically more expensive than simpler solenoid designs.

Reliability Aspects and Maintenance Tips

The reliability of the 2014 Maxima's step motor is closely tied to proper maintenance of the CVT. Regular transmission fluid changes, using the correct type of fluid specified by Nissan, are crucial. Contaminated fluid can cause wear and damage to the step motor and other transmission components. Overheating can also shorten the lifespan of the motor.

Common failure modes include:

- Winding Failure: Open or shorted windings can prevent the motor from operating correctly.

- Bearing Failure: Worn bearings can cause the motor to bind or produce excessive noise.

- Contamination: Debris in the transmission fluid can clog the motor's internal passages or damage its moving parts.

- Electrical Connection Issues: Corrosion or loose connections can disrupt the electrical signals to the motor.

Maintenance Tips for Automotive Professionals:

- Regular Fluid Checks: Inspect the transmission fluid for color, odor, and contamination.

- Use OEM-Specified Fluid: Using the correct fluid is essential for proper transmission operation and step motor longevity.

- Proper Diagnostic Procedures: Use a scan tool to check for diagnostic trouble codes (DTCs) related to the transmission and step motor.

- Electrical Testing: Perform electrical tests on the step motor windings to check for opens, shorts, or excessive resistance.

- Visual Inspection: Inspect the step motor and its wiring harness for damage or corrosion.

- Avoid Overheating: Address any cooling system issues promptly to prevent transmission overheating.

When replacing the step motor, it's essential to follow the manufacturer's instructions carefully. Proper installation and calibration are crucial for ensuring optimal performance. Always reset the transmission's adaptive learning after replacing the step motor.

Future Trends

The automotive industry is rapidly evolving, with a growing emphasis on electrification and advanced driver-assistance systems (ADAS). While the 2014 Maxima uses a traditional step motor in a CVT, future transmission designs are likely to incorporate more sophisticated control systems. These systems may utilize:

- Sensor Integration: Incorporating more sensors to provide real-time feedback on transmission performance, allowing for more precise control.

- Adaptive Algorithms: Implementing advanced algorithms that learn and adapt to the driver's behavior, optimizing shift strategies for performance and fuel efficiency.

- Electric Actuators: Replacing hydraulic systems with electric actuators, potentially improving efficiency and reducing complexity.

- AI-Powered Control: Integrating artificial intelligence to predict driver demand and optimize transmission control in real-time.

As hybrid and electric vehicles become more prevalent, the role of traditional transmissions is diminishing. However, even in these vehicles, electric motors require sophisticated control systems to manage torque and speed. The principles of precise motor control, as exemplified by the 2014 Maxima's step motor, will continue to be relevant in future automotive technologies.

Conclusion

The 2014 Nissan Maxima's step motor represents a key component in its CVT system, enabling smooth and efficient operation. Understanding its technical specifications, engineering considerations, and potential failure modes is crucial for automotive professionals. As the automotive industry advances, the principles of precise motor control will continue to be essential, paving the way for more sophisticated and efficient vehicle technologies. Technicians equipped with the knowledge to diagnose and repair these systems will be well-positioned to succeed in the evolving automotive landscape. The shift towards electric vehicles and advanced driver-assistance systems reinforces the need for expertise in mechatronics and control systems, ensuring the automotive industry remains at the forefront of innovation.

The ability to adapt and learn new technologies will be paramount for automotive professionals in the years to come.