2015 Nissan Sentra Valve Body

The 2015 Nissan Sentra, while often praised for its fuel efficiency and affordability, isn't immune to its share of mechanical gremlins. Among these, issues related to the valve body in its Continuously Variable Transmission (CVT) can be particularly troublesome. This article delves into the intricacies of the 2015 Sentra's valve body, exploring its function, common problems, diagnostic procedures, repair options, and preventative measures.

Understanding the Valve Body

At its core, the valve body is the hydraulic control center of an automatic transmission, including CVTs. Think of it as the brain of the transmission, directing the flow of transmission fluid to various clutches and actuators. These components then engage the appropriate gears (or, in the case of a CVT, adjust the pulley ratios) to provide the correct driving ratio for varying speeds and loads. The valve body contains a complex network of channels, valves, and solenoids. These solenoids, controlled by the Transmission Control Module (TCM), open and close to regulate fluid pressure. This fluid pressure is what physically actuates the shifting mechanisms.

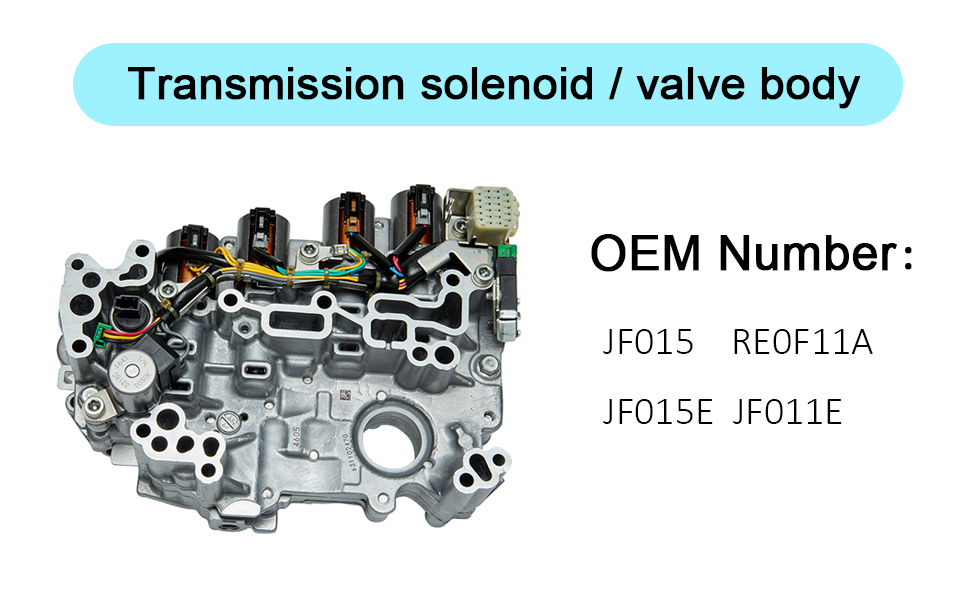

In the 2015 Nissan Sentra, the CVT, specifically the Jatco JF015E (or a variant thereof depending on the engine), uses a sophisticated valve body to manage the continuously variable ratios. The JF015E is a common CVT found in many compact vehicles, not just Nissans, but its susceptibility to valve body issues remains a recurring theme.

Common Problems with the 2015 Sentra Valve Body

Several telltale signs can indicate a problem with the valve body in a 2015 Sentra. These issues often manifest as:

- Erratic Shifting: This is perhaps the most common symptom. The transmission may hesitate, shift abruptly, or fail to shift altogether. In a CVT, this might present as surging or a lack of response to throttle input.

- Slipping: The engine revs higher than normal without a corresponding increase in speed. This indicates that the clutches or belt within the CVT are not properly engaging.

- Hard Shifting: Shifts feel harsh and jarring, rather than smooth and seamless.

- Delayed Engagement: A noticeable delay between putting the car in gear (Drive or Reverse) and the transmission actually engaging.

- Check Engine Light: The TCM may detect abnormalities in the transmission's operation and trigger the check engine light. Diagnostic Trouble Codes (DTCs) related to solenoids, pressure sensors, or overall transmission performance are often stored. Common codes include P0776 (Pressure Control Solenoid "B" Performance or Stuck Off), P0777 (Pressure Control Solenoid "B" Stuck On), and related pressure control circuit codes.

- Limp Mode: In severe cases, the TCM may activate "limp mode," restricting the transmission to a single gear (or a very limited range of ratios in a CVT) to prevent further damage.

These problems are often caused by:

- Dirty Transmission Fluid: Contaminated fluid can clog the narrow channels and passages within the valve body, hindering the movement of valves and solenoids.

- Worn or Stuck Solenoids: The solenoids themselves can fail due to wear and tear, electrical issues, or debris accumulation.

- Damaged Valves: The valves within the valve body can become worn, scored, or stuck, preventing proper fluid pressure regulation.

- Internal Leaks: Worn seals and gaskets can lead to internal leaks within the valve body, reducing fluid pressure and affecting shift quality.

Diagnosing Valve Body Problems

A thorough diagnosis is crucial before attempting any repairs. Here's a typical diagnostic process:

- Initial Inspection: Check the transmission fluid level and condition. Low or dark, burnt-smelling fluid is a red flag.

- Scan for DTCs: Use an OBD-II scanner to retrieve any stored Diagnostic Trouble Codes (DTCs) related to the transmission. Pay close attention to codes related to solenoids, pressure sensors, and transmission performance.

- Fluid Pressure Test: A transmission pressure gauge can be used to measure fluid pressure at various test ports on the transmission. Abnormal pressure readings can indicate a valve body issue.

- Solenoid Testing: Each solenoid can be tested individually using a multimeter to check its resistance and voltage. A malfunctioning solenoid will typically have an abnormal resistance reading or fail to activate when voltage is applied.

- Valve Body Inspection (Requires Removal): If other tests are inconclusive, the valve body may need to be removed from the transmission for a visual inspection. Look for signs of wear, damage, and debris accumulation. A closer inspection might involve using a specialized vacuum test to check for leaks around the valves.

Important Note: Diagnosing valve body issues often requires specialized tools and knowledge. It's generally recommended to consult a qualified mechanic or transmission specialist.

Repair Options

Once a valve body problem has been confirmed, there are several repair options:

- Valve Body Cleaning: In some cases, simply cleaning the valve body and replacing the transmission fluid can resolve the issue. This involves disassembling the valve body, cleaning all the components with a solvent, and reassembling it with new seals and gaskets. This is most effective if the problem is caused by contaminated fluid.

- Solenoid Replacement: If a specific solenoid is found to be faulty, it can be replaced individually. New or remanufactured solenoids are readily available.

- Valve Body Rebuild: A more comprehensive repair involves rebuilding the entire valve body. This includes replacing all the valves, solenoids, seals, and gaskets. Rebuilt valve bodies are often available as a cost-effective alternative to buying a new one.

- Valve Body Replacement: If the valve body is severely damaged or worn, it may need to be replaced entirely. New or remanufactured valve bodies are available from various sources.

- Transmission Replacement: In severe cases, where the valve body damage is extensive or other internal transmission components are also damaged, a complete transmission replacement may be the only option.

The cost of repair can vary significantly depending on the chosen option. Cleaning and solenoid replacement are the least expensive, while transmission replacement is the most expensive. A rebuilt valve body typically falls somewhere in between.

Preventative Maintenance

Preventative maintenance is key to extending the life of the 2015 Sentra's CVT and minimizing the risk of valve body problems:

- Regular Transmission Fluid Changes: Follow the manufacturer's recommended service intervals for transmission fluid changes. Using the correct type of fluid is also crucial. Nissan CVTs require specific NS-2 or NS-3 fluid. Using the wrong fluid can cause serious damage. Changing the fluid every 30,000 to 60,000 miles is generally recommended, but consult your owner's manual for the specific interval for your vehicle.

- Avoid Aggressive Driving: Aggressive acceleration and hard braking can put excessive stress on the transmission, accelerating wear and tear.

- Address Problems Early: If you notice any signs of transmission problems, such as erratic shifting or slipping, have them diagnosed and repaired promptly. Ignoring minor issues can lead to more serious and costly problems down the road.

- Consider an External Transmission Cooler: For vehicles that are frequently used for towing or driven in hot climates, an external transmission cooler can help to reduce transmission fluid temperatures and extend its lifespan.

By understanding the function of the valve body, recognizing common problems, and following preventative maintenance practices, owners of 2015 Nissan Sentras can help to ensure the longevity and reliability of their vehicles' transmissions.

Aftermarket Options and Considerations

While OEM parts are generally recommended for repairs, the aftermarket offers alternatives for valve bodies and solenoids. Some aftermarket companies claim to offer improved performance or durability. However, it's essential to research and choose reputable brands with proven track records. Always ensure that the aftermarket parts are compatible with your specific 2015 Sentra model and transmission type.

Furthermore, consider the warranty offered on aftermarket parts. A longer warranty can provide peace of mind in case of premature failure.

Finally, when replacing the valve body or any transmission components, it's crucial to have the transmission properly programmed or "flashed" with the latest software updates. This ensures that the TCM is correctly calibrated to the new components and can optimize transmission performance.