2016 Nissan Rogue Transmission Fluid Pressure Sensor Location

The 2016 Nissan Rogue, a popular compact SUV, utilizes a Continuously Variable Transmission (CVT) manufactured by Jatco, designated as the JF016E/RE0F10D. Understanding the location and function of the Transmission Fluid Pressure (TFP) sensor within this transmission is crucial for automotive professionals diagnosing and repairing transmission-related issues. This article delves into the specifics of the TFP sensor in the 2016 Rogue, comparing it to alternative sensor technologies, exploring its reliability, providing maintenance tips, and examining future trends in transmission sensor technology.

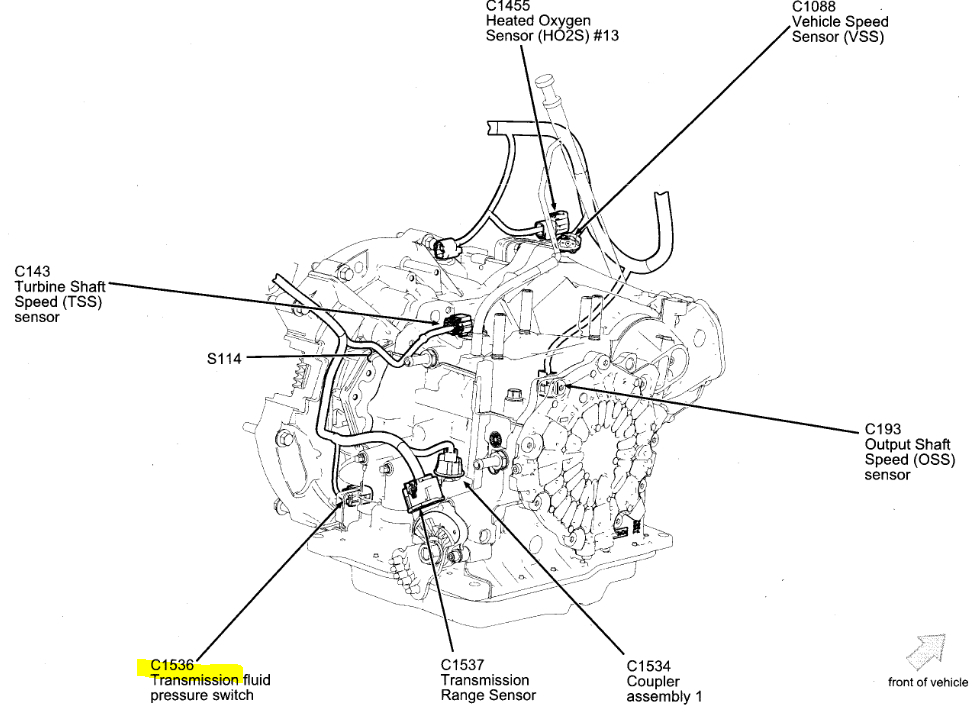

Location and Function of the TFP Sensor

The 2016 Nissan Rogue's CVT utilizes multiple TFP sensors. Typically, you'll find at least two: one measuring the primary line pressure and another monitoring the secondary line pressure. These sensors are strategically located within the transmission valve body. Accessing them generally requires removing the transmission pan and valve body assembly. The exact position can vary slightly depending on the specific sub-model and production run, but they are usually mounted directly onto the valve body casting, often near the solenoids and other hydraulic control components.

The TFP sensors are responsible for monitoring the hydraulic pressure within the transmission. This pressure is directly related to the force applied to the variator pulleys (the heart of the CVT), and consequently, the gear ratio being used. The sensors convert the hydraulic pressure into an electrical signal, which is then sent to the Transmission Control Module (TCM). The TCM uses this information to:

- Control the operation of the pressure control solenoids.

- Optimize the transmission's performance for fuel efficiency and smooth operation.

- Detect anomalies and trigger diagnostic trouble codes (DTCs) related to pressure imbalances or sensor failures.

Technical Specifications and Engineering Choices

The TFP sensors used in the JF016E/RE0F10D CVT are typically piezoresistive sensors. These sensors employ a silicon diaphragm with piezoresistive elements embedded within. When pressure is applied, the diaphragm deflects, causing a change in the resistance of the piezoresistive elements. This resistance change is proportional to the applied pressure and is converted into a voltage signal. Typical output voltage ranges are 0.5V to 4.5V, corresponding to the minimum and maximum pressure ranges the sensor is designed to measure. The specific pressure range the sensor is designed to measure varies according to the specific location and function.

Nissan's engineering choice of using piezoresistive sensors stems from their:

- Small size and compact design: Essential for integration within the valve body.

- Relatively low cost: Compared to more advanced pressure sensing technologies.

- Acceptable accuracy and reliability: For automotive transmission control applications.

- Robustness to vibration and temperature variations: Considering the harsh operating environment within the transmission.

The sensor housings are typically constructed from durable plastics or metals designed to withstand the high temperatures and pressures within the transmission. The electrical connectors are also designed for reliable operation in a fluid-filled environment, often featuring multiple seals to prevent fluid ingress.

Real-World Performance and Comparison with Alternatives

In real-world applications, the TFP sensors in the 2016 Rogue's CVT generally perform reliably. However, they are susceptible to failure due to:

- Contamination from degraded transmission fluid: Sludge and debris can clog the sensor ports or damage the diaphragm.

- Electrical connection issues: Corrosion or loose connections can disrupt the signal.

- Internal sensor failure: The piezoresistive elements can degrade over time due to thermal stress and mechanical fatigue.

When a TFP sensor fails, it can manifest in various symptoms, including:

- Erratic shifting or transmission slippage.

- Hesitation or lack of power during acceleration.

- Illumination of the check engine light (CEL) with DTCs related to TFP sensor readings (e.g., P0720, P0721, P0722, P0723).

- Complete transmission failure in severe cases.

Alternative sensor technologies for pressure sensing include:

- Strain gauge sensors: Offer higher accuracy and linearity but are generally more expensive and sensitive to vibration.

- Capacitive pressure sensors: Utilize a change in capacitance due to diaphragm deflection. These are more complex to manufacture but offer good sensitivity and stability.

- Optical pressure sensors: Measure pressure by detecting changes in the properties of light as it passes through a pressure-sensitive material. These are highly accurate but are typically used in specialized applications due to their high cost and complexity.

Pros and Cons of Piezoresistive Sensors (vs. Alternatives):

| Feature | Piezoresistive Sensors | Strain Gauge Sensors | Capacitive Sensors |

|---|---|---|---|

| Accuracy | Moderate | High | High |

| Cost | Low | Moderate | Moderate to High |

| Complexity | Simple | Moderate | Complex |

| Robustness | Good | Fair | Good |

| Size | Compact | Moderate | Moderate |

| Linearity | Moderate | High | Moderate |

Given the cost-sensitive nature of mass-produced automotive components and the acceptable performance characteristics of piezoresistive sensors, they remain a suitable choice for TFP sensing in transmissions like the JF016E/RE0F10D.

Reliability Aspects and Maintenance Tips

The reliability of the TFP sensors is directly linked to the quality of the transmission fluid and the frequency of fluid changes. Regular transmission fluid changes, following Nissan's recommended service intervals (typically every 30,000 to 60,000 miles depending on driving conditions), are crucial for preventing fluid degradation and contamination that can damage the sensors.

Maintenance Tips for Automotive Professionals:

- Use Genuine Nissan Transmission Fluid (NS-3): Using the correct fluid is essential for proper transmission operation and sensor longevity.

- Inspect Transmission Fluid Condition Regularly: Check for discoloration, burning odor, or the presence of metal particles.

- Perform Thorough Flushing During Fluid Changes: This helps remove contaminants that can damage the sensors.

- Check Sensor Connectors for Corrosion: Clean and apply dielectric grease to prevent future corrosion.

- Use a Scan Tool to Monitor Sensor Readings: Compare the sensor readings with the manufacturer's specifications to identify potential issues early.

- Proper Diagnostic Procedures: Always consult the Nissan service manual for proper diagnostic procedures and troubleshooting steps.

When replacing a TFP sensor, always use a high-quality OEM or reputable aftermarket replacement. Ensure the new sensor is properly calibrated and torqued to the manufacturer's specifications. After installation, clear any stored DTCs and perform a transmission adaptive learning procedure (if required) to ensure optimal performance.

Future Trends

The automotive industry is constantly evolving, and transmission sensor technology is no exception. Future trends in this area include:

- Wireless Sensors: Eliminating the need for physical wiring harnesses, reducing complexity and improving reliability.

- Integrated Sensors: Combining multiple sensor functions into a single unit, further reducing size and cost.

- Advanced Sensor Diagnostics: Incorporating self-diagnostic capabilities into the sensors, allowing for more accurate and timely detection of potential failures.

- More Robust Materials: Employing materials with improved resistance to high temperatures, pressures, and corrosive fluids.

- AI-Powered Data Analysis: Using artificial intelligence to analyze sensor data in real-time, optimizing transmission performance and predicting potential failures before they occur.

These advancements will lead to more efficient, reliable, and intelligent transmissions, contributing to improved fuel economy, reduced emissions, and enhanced driving experience.

Conclusion

The Transmission Fluid Pressure sensor is a critical component in the 2016 Nissan Rogue's CVT, responsible for providing essential data for accurate transmission control. Understanding its location, function, and potential failure modes is crucial for automotive professionals involved in diagnosing and repairing transmission-related issues. By adhering to proper maintenance procedures, using quality replacement parts, and staying informed about future technological advancements, automotive professionals can ensure the reliable and efficient operation of these transmissions. The trend towards more sophisticated and integrated sensor technologies reflects the automotive industry's ongoing pursuit of increased efficiency, reliability, and performance, paving the way for future generations of advanced transmissions.