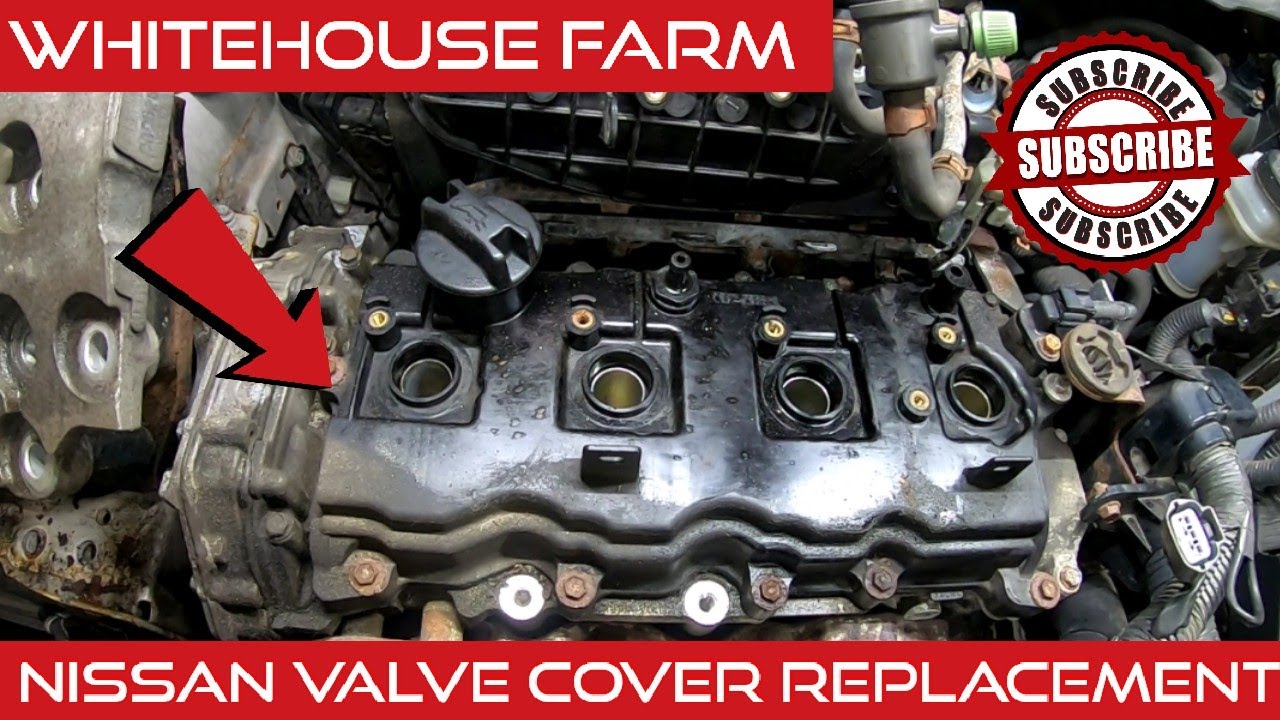

2018 Nissan Rogue Valve Cover

The 2018 Nissan Rogue, a popular compact SUV, relies on a 2.5-liter QR25DE engine for its power. Atop this engine, protecting its intricate valvetrain, sits the valve cover. While seemingly simple, the valve cover plays a crucial role in the engine's overall health and performance. This guide delves into the technical aspects of the 2018 Nissan Rogue's valve cover, exploring its function, construction, potential issues, and common maintenance procedures.

Function and Purpose

The valve cover, as its name suggests, directly covers the engine's valves, rocker arms (or, in this case, the camshafts which actuate the valves directly), and associated components within the cylinder head. Its primary function is to:

- Seal the Top of the Cylinder Head: This is perhaps the most critical function. The valve cover creates a sealed environment to prevent oil from escaping the engine. Oil is constantly splashed around the valvetrain to lubricate moving parts, and without a proper seal, this oil would leak out, leading to reduced oil levels, potential engine damage, and a messy engine bay.

- Protect the Valvetrain: The cover acts as a physical barrier, shielding the delicate valvetrain components from external contaminants such as dirt, debris, and moisture. These contaminants, if allowed to enter, can accelerate wear and tear, reducing the lifespan and performance of the valvetrain.

- Provide a Mounting Point: The valve cover often serves as a mounting point for various engine components, such as the PCV (Positive Crankcase Ventilation) valve and sometimes ignition coils.

- Noise Reduction: To a lesser extent, the valve cover can contribute to noise reduction by dampening some of the mechanical noise generated by the moving valvetrain components.

Construction and Materials

The valve cover on the 2018 Nissan Rogue is typically made from either molded plastic or cast aluminum. Each material offers distinct advantages and disadvantages:

Plastic Valve Cover

Plastic valve covers, often made from reinforced nylon or similar polymers, are becoming increasingly common due to their:

- Light Weight: Reduced weight contributes to improved fuel efficiency.

- Cost-Effectiveness: Plastic valve covers are generally cheaper to manufacture than their aluminum counterparts.

- Design Flexibility: Plastic molding allows for complex shapes and integrated features, such as PCV valve housings.

- Thermal Insulation: Plastic offers better thermal insulation, which can help to keep the oil cooler.

However, plastic valve covers are also susceptible to:

- Cracking: Over time, the plastic can become brittle due to heat cycling and exposure to engine oil, leading to cracks and leaks.

- Warping: High temperatures can cause the plastic to warp, compromising the seal between the valve cover and the cylinder head.

Aluminum Valve Cover

Aluminum valve covers offer greater durability and heat resistance compared to plastic. Their key advantages include:

- Durability: Aluminum is a stronger and more durable material, making it less prone to cracking or warping.

- Heat Dissipation: Aluminum conducts heat better than plastic, which can help to dissipate heat from the cylinder head.

- Aesthetics: Aluminum valve covers can often be polished or painted for a more aesthetically pleasing appearance.

However, aluminum valve covers also have some drawbacks:

- Heavier Weight: Aluminum is heavier than plastic, which can slightly reduce fuel efficiency.

- Higher Cost: Aluminum valve covers are generally more expensive to manufacture.

Regardless of the material, the valve cover employs a gasket to create a tight seal against the cylinder head. This gasket is typically made of rubber, silicone, or a combination of materials designed to withstand high temperatures and resist degradation from engine oil.

Potential Issues and Symptoms

The valve cover, and particularly its gasket, is a common source of engine oil leaks. Here are some potential issues and their associated symptoms:

- Valve Cover Gasket Leak:

- Symptoms:

- Visible oil leaks around the valve cover, often dripping onto the exhaust manifold (resulting in a burning oil smell).

- Low engine oil level.

- Oil spots on the ground beneath the engine.

- Smoke from the engine bay (if oil drips onto hot exhaust components).

- Causes: Deterioration of the gasket due to age, heat, and exposure to engine oil; improper installation of the gasket; warped or cracked valve cover.

- Symptoms:

- Cracked Valve Cover:

- Symptoms: Similar to a valve cover gasket leak, but the leak may be more severe and the crack may be visible upon inspection.

- Causes: Over-tightening of valve cover bolts (especially on plastic valve covers); impact damage; material fatigue due to heat cycling.

- Warped Valve Cover:

- Symptoms: Difficult to diagnose without removing the valve cover. May cause an uneven seal, leading to oil leaks.

- Causes: Overheating of the engine; uneven tightening of valve cover bolts.

- PCV Valve Issues (if integrated into the valve cover):

- Symptoms: Rough idling; poor fuel economy; increased oil consumption; vacuum leaks.

- Causes: Clogged or malfunctioning PCV valve.

Inspection and Maintenance

Regular inspection and maintenance can help prevent valve cover-related issues. Here's what to look for:

- Visual Inspection: Regularly inspect the valve cover for any signs of oil leaks, cracks, or damage. Pay close attention to the area around the valve cover gasket.

- Torque Check: Periodically check the torque of the valve cover bolts. Refer to the vehicle's service manual for the correct torque specifications. Avoid over-tightening, especially on plastic valve covers, as this can cause cracking or warping.

- PCV Valve Replacement: If the PCV valve is integrated into the valve cover (or easily accessible), replace it according to the manufacturer's recommended service interval. A faulty PCV valve can contribute to oil leaks and other engine problems.

- Gasket Replacement: If you notice any signs of a valve cover gasket leak, replace the gasket immediately. Always use a high-quality gasket and follow the manufacturer's instructions for installation. Clean the mating surfaces of the valve cover and cylinder head thoroughly before installing the new gasket.

- Valve Cover Replacement: If the valve cover is cracked or warped, it should be replaced. When replacing the valve cover, always use a new gasket and follow the manufacturer's instructions for installation.

Removal and Installation (Simplified Overview)

Note: This is a simplified overview. Always consult the vehicle's service manual for specific instructions and torque specifications.

Removal:

- Disconnect the negative battery cable.

- Remove any components that are obstructing access to the valve cover, such as air intake ducts, wiring harnesses, or PCV valve hoses.

- Carefully disconnect any electrical connectors or vacuum hoses attached to the valve cover.

- Loosen the valve cover bolts gradually and evenly, working in a crisscross pattern.

- Remove the valve cover.

- Carefully remove the old valve cover gasket.

- Clean the mating surfaces of the valve cover and cylinder head thoroughly.

Installation:

- Install the new valve cover gasket. Ensure that it is properly seated in the valve cover groove.

- Carefully position the valve cover onto the cylinder head.

- Install the valve cover bolts and tighten them gradually and evenly, working in a crisscross pattern. Use a torque wrench to tighten the bolts to the manufacturer's specified torque. Under-tightening can cause leaks, while over-tightening can damage the valve cover.

- Reconnect any electrical connectors or vacuum hoses that were disconnected.

- Reinstall any components that were removed to access the valve cover.

- Reconnect the negative battery cable.

- Start the engine and check for leaks.

Conclusion

The valve cover on the 2018 Nissan Rogue's QR25DE engine is a critical component that protects the valvetrain and prevents oil leaks. Understanding its function, construction, potential issues, and maintenance requirements is essential for ensuring the longevity and performance of the engine. By regularly inspecting the valve cover and addressing any issues promptly, you can prevent costly engine repairs and keep your Rogue running smoothly for years to come.