350z Lower Control Arm Replacement

The Nissan 350z, a performance icon from the early 2000s, continues to be a favorite among enthusiasts. A crucial component impacting its handling and overall driving experience is the lower control arm. This article delves deep into the intricacies of 350z lower control arm replacement, providing a technical and practical guide for automotive professionals.

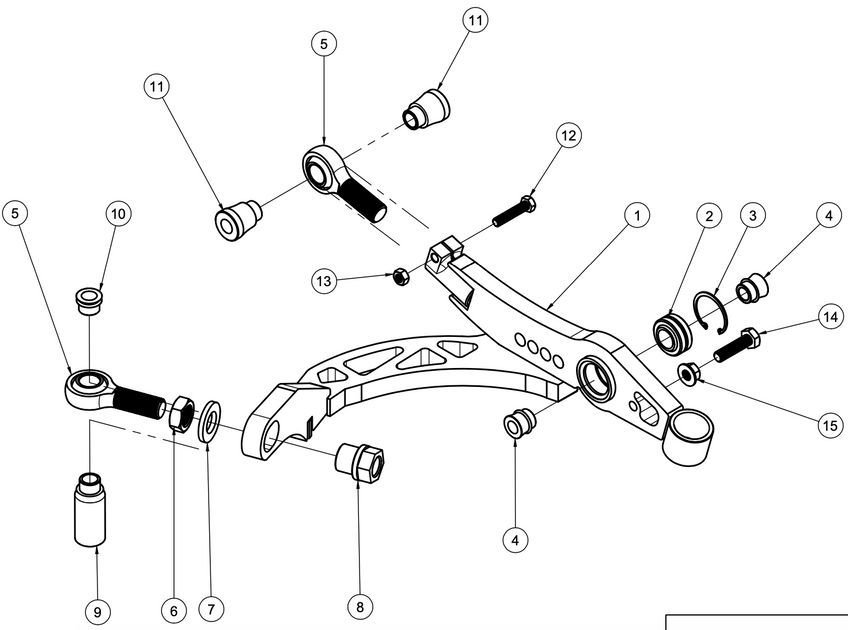

Understanding the 350z Lower Control Arm

The lower control arm (LCA) on the 350z is a critical suspension component connecting the wheel hub to the vehicle's chassis. It plays a vital role in maintaining wheel alignment, absorbing road shocks, and enabling controlled movement during cornering and braking. It primarily handles longitudinal and lateral forces acting upon the suspension system.

Technical Specifications: The OEM 350z LCA is typically constructed from stamped steel or cast aluminum (depending on the specific model and year). Key dimensions to consider are length, bushing diameter, and ball joint size. Torque specifications for LCA mounting bolts are crucial for proper installation and preventing premature failure. These specs vary slightly between models but typically fall within the 80-100 ft-lb range for the chassis bolts and 40-60 ft-lb for the ball joint.

Engineering Choices: Nissan's engineering team made deliberate choices in the LCA's design to achieve a balance between performance, cost, and durability. Stamped steel LCAs offer a cost-effective solution with sufficient strength for general road use. Aluminum LCAs, often found in higher-performance models or aftermarket upgrades, reduce unsprung weight, leading to improved handling and responsiveness. The bushing durometer also plays a significant role. Softer bushings prioritize ride comfort, while stiffer bushings enhance handling precision but can compromise NVH (Noise, Vibration, and Harshness).

Common Issues and Symptoms

Several issues can necessitate LCA replacement. These include:

- Damaged ball joint: Excessive play in the ball joint, often identified during inspection or causing knocking noises.

- Worn bushings: Cracked, torn, or excessively compliant bushings that result in vague steering, instability, and uneven tire wear.

- Bent or damaged arm: Caused by impacts, accidents, or extreme stress.

- Corrosion: Rust can weaken the LCA, especially in regions with harsh weather conditions.

Symptoms of a failing LCA include:

- Knocking or clunking noises from the suspension, particularly when going over bumps.

- Vague or loose steering feel.

- Uneven tire wear.

- Vehicle pulling to one side.

- Vibration or instability at higher speeds.

Replacement Procedure: A Step-by-Step Guide

Replacing a 350z LCA requires careful attention to detail and adherence to proper safety procedures. Here's a general overview:

- Safety First: Disconnect the negative battery terminal. Securely lift the vehicle using a jack and support it with jack stands. Never work under a vehicle supported only by a jack.

- Wheel Removal: Remove the wheel on the side where the LCA is being replaced.

- Disconnect ABS Sensor (If Applicable): Carefully disconnect the ABS sensor wire from the LCA to avoid damage.

- Disconnect Sway Bar Link: Detach the sway bar link from the LCA. A penetrating lubricant may be necessary.

- Separate Ball Joint: Disconnect the ball joint from the steering knuckle. This can be achieved using a ball joint separator tool or a pickle fork. Be extremely careful not to damage the ball joint boot.

- Remove LCA Mounting Bolts: Remove the bolts securing the LCA to the chassis. These bolts can be seized, so penetrating lubricant and a breaker bar might be required. Support the LCA during removal to prevent it from dropping suddenly.

- Install New LCA: Install the new LCA, ensuring the mounting bolts are properly aligned. Do not fully tighten the bolts at this stage.

- Reconnect Ball Joint: Reconnect the ball joint to the steering knuckle. Tighten the ball joint nut to the manufacturer's specified torque.

- Reconnect Sway Bar Link: Reattach the sway bar link to the LCA. Tighten the nut to the specified torque.

- Reconnect ABS Sensor (If Applicable): Reconnect the ABS sensor wire to the LCA.

- Final Tightening: With the vehicle's suspension loaded (either on a drive-on ramp or with the weight of the vehicle on the wheels after a short drive), tighten the LCA mounting bolts to the manufacturer's specified torque. This is crucial for preventing bushing pre-load and ensuring proper suspension articulation.

- Wheel Installation: Reinstall the wheel and tighten the lug nuts to the specified torque.

- Alignment: After replacing the LCA, a wheel alignment is absolutely necessary to ensure proper handling and prevent premature tire wear.

OEM vs. Aftermarket LCAs: A Comparative Analysis

When replacing the LCA, the choice often comes down to OEM (Original Equipment Manufacturer) parts or aftermarket alternatives. Here's a comparison:

- OEM LCAs:

- Pros: Guaranteed fitment, quality materials, designed for optimal performance and durability, maintain vehicle's original handling characteristics.

- Cons: Generally more expensive than aftermarket options, may not offer performance enhancements for track use.

- Aftermarket LCAs:

- Pros: Can offer performance improvements (e.g., adjustable length for camber adjustment, stiffer bushings for enhanced handling), potentially lower cost, wider range of options (e.g., tubular arms, aluminum arms).

- Cons: Fitment can be an issue with some brands, quality can vary significantly, may introduce NVH, may require additional modifications or adjustments, potential for decreased durability compared to OEM.

Adjustable LCAs: These aftermarket options offer the ability to adjust camber, which can be beneficial for lowered vehicles or those used for track purposes. However, they also introduce potential points of failure (e.g., adjustment bolts loosening) and require precise setup to avoid negatively impacting handling.

Alternatives to Full LCA Replacement

In some cases, a full LCA replacement might not be necessary. If the bushings are the only issue, replacing the bushings alone can be a cost-effective solution. However, this requires specialized tools and can be time-consuming. Similarly, if the ball joint is the only problem, replacing the ball joint (if it's replaceable on the specific LCA design) can save money. However, consider the age and condition of the rest of the LCA before opting for a partial repair.

Reliability and Maintenance Tips

To ensure the longevity of your 350z's LCAs:

- Regular Inspection: Periodically inspect the LCAs for signs of damage, corrosion, or worn bushings.

- Proper Torque: Ensure all mounting bolts are tightened to the manufacturer's specified torque.

- Wheel Alignment: Maintain proper wheel alignment to minimize stress on the LCAs and prevent premature wear.

- Avoid Impacts: Avoid hitting potholes or other obstacles that can damage the LCAs.

- Lubrication: If the ball joint has a grease fitting, lubricate it regularly with a high-quality grease.

- Corrosion Protection: In regions with harsh weather, consider applying a rust inhibitor to the LCAs to prevent corrosion.

Future Trends in Suspension Technology

The automotive industry is constantly evolving, and suspension technology is no exception. Some future trends to watch for include:

- Active Suspension Systems: More sophisticated active suspension systems that can automatically adjust damping and ride height based on road conditions and driving style.

- Lightweight Materials: Increased use of lightweight materials like carbon fiber and advanced alloys to further reduce unsprung weight.

- Smart Suspension Components: Sensors and actuators integrated into suspension components to monitor performance and provide real-time feedback.

- 3D-Printed Components: 3D printing may play a larger role in the manufacturing of custom or low-volume suspension parts.

Conclusion

The 350z lower control arm is a crucial component that significantly impacts the vehicle's handling and overall driving experience. Automotive professionals must possess a thorough understanding of its function, common issues, replacement procedures, and available alternatives. By adhering to proper maintenance practices and staying informed about future trends in suspension technology, technicians can ensure the continued performance and reliability of this iconic sports car. The increasing emphasis on performance, handling, and efficiency in the automotive industry underscores the critical role that suspension systems, including components like the LCA, will play in shaping the future of driving.