350z Valve Cover Torque Specs

Alright, let's talk valve covers on your 350z. Specifically, getting those torque specs right. This isn’t just about tightening bolts; it’s about ensuring a proper seal to prevent oil leaks and, more importantly, avoiding damage to the valve covers themselves or the cylinder head. An improperly torqued valve cover can lead to a whole host of problems, from minor annoyances to major engine issues.

Understanding the Importance of Torque Specs

Before diving into the numbers, let's clarify why torque specs are crucial. Torque is a rotational force. Applying the correct torque to a fastener – in this case, the valve cover bolts – ensures the right amount of clamping force. Too little torque, and the gasket won't seal properly, leading to oil leaks. Too much, and you risk stripping threads, cracking the valve cover (especially if it's the original plastic one), or even warping the cylinder head. None of these are desirable outcomes.

Torque is measured in units of force times distance. In the automotive world, you'll often see it expressed in foot-pounds (ft-lbs) or Newton-meters (Nm). Make sure you're using the correct units for your torque wrench and the specified torque value.

350z Valve Cover Torque Specs: The Numbers You Need

For the 350z, the valve cover torque specification is relatively low, highlighting the importance of accuracy. Whether you have a VQ35DE (2003-2006) or a VQ35HR (2007-2008) engine, the torque specs are generally the same:

- Valve Cover Bolts: 87 in-lbs (inch-pounds) or 9.8 Nm

Notice that's inch-pounds, not foot-pounds! It's easy to make a mistake here, so double-check your torque wrench setting. Using foot-pounds when it should be inch-pounds can easily lead to overtightening and damage.

Also, remember that these are general guidelines. Always refer to your specific 350z's factory service manual (FSM) for the most accurate and up-to-date information. The FSM is the bible for your car and contains detailed instructions for every repair and maintenance procedure.

Tools You'll Need

To properly torque your 350z valve covers, you'll need the following tools:

- Torque Wrench: A torque wrench capable of accurately measuring inch-pounds (or Newton-meters). A 1/4-inch drive torque wrench is ideal for these low torque values. A larger wrench will not be as precise at the lower end of its range.

- Socket Set: A socket set with the appropriate size socket for the valve cover bolts. Usually, a 10mm socket will do the trick.

- Extension: An extension for your socket wrench might be necessary to reach some of the bolts.

- Clean Rags: For cleaning surfaces.

- Gasket Scraper: For removing old gasket material (if replacing the gasket).

- New Valve Cover Gaskets: Highly recommended to replace these whenever you remove the valve covers.

- Thread Locker (Optional): Some people prefer to use a small amount of thread locker on the bolts, but it's generally not required if the bolts are clean and in good condition. If you choose to use it, use a low-strength thread locker like Loctite 242 (blue).

The Torqueing Procedure: Step-by-Step

Here's a breakdown of the procedure for properly torqueing your 350z valve covers:

- Preparation:

- Make sure the engine is cool to the touch. Working on a hot engine can be dangerous and can also affect the torque readings.

- Disconnect the negative battery terminal for safety.

- Remove any components that are in the way of accessing the valve covers, such as the intake manifold, wiring harnesses, and hoses. Take pictures as you go to help you remember where everything goes.

- Clean the cylinder head surface where the valve cover gasket sits. Use a gasket scraper to remove any old gasket material. Be careful not to scratch the cylinder head surface.

- Install the new valve cover gaskets. Make sure they are properly seated in the valve cover grooves.

- Install the Valve Covers:

- Carefully place the valve covers onto the cylinder head, ensuring the gaskets are properly aligned.

- Install the valve cover bolts by hand, tightening them only until they are snug. Do not overtighten them at this stage.

- Torqueing:

- Set your torque wrench to 87 in-lbs (9.8 Nm).

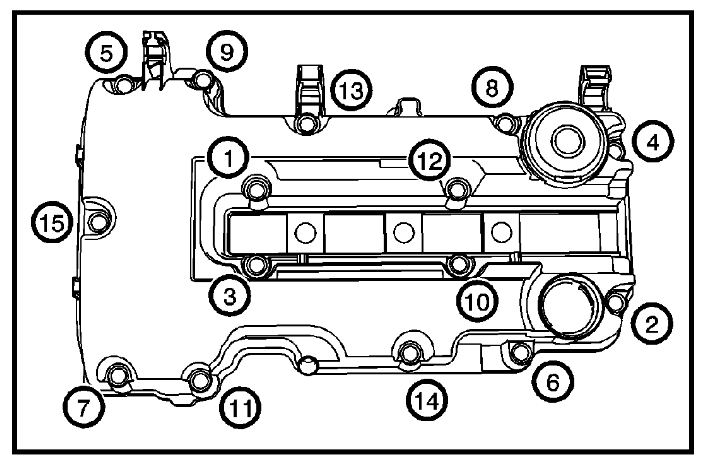

- Important: Use a torque sequence! This distributes the clamping force evenly and prevents warping. A common torque sequence is a crisscross pattern, starting from the center and working your way outwards. Refer to your FSM for the specific torque sequence for your 350z.

- Torque each bolt to the specified torque value in the correct sequence. Make sure to use a smooth, controlled motion. Do not jerk the torque wrench.

- After completing the torque sequence once, repeat it again to ensure all bolts are properly torqued.

- Reassembly:

- Reinstall any components that you removed in step 1, such as the intake manifold, wiring harnesses, and hoses.

- Reconnect the negative battery terminal.

Common Mistakes to Avoid

Here are some common mistakes people make when torqueing valve covers:

- Using the wrong torque units: As mentioned earlier, this is a common mistake. Double-check that you're using inch-pounds and not foot-pounds.

- Overtightening the bolts: This is the most common cause of stripped threads and cracked valve covers. If you're not sure, it's better to undertighten slightly and then re-torque than to overtighten.

- Forgetting the torque sequence: Torqueing the bolts in a random order can lead to uneven clamping force and leaks.

- Using a worn-out torque wrench: Torque wrenches can lose their accuracy over time. If you suspect your torque wrench is not accurate, have it calibrated.

- Reusing old gaskets: Old gaskets can become hard and brittle, and they may not seal properly. Always replace the valve cover gaskets when you remove the valve covers.

- Not cleaning the surfaces: A clean surface is essential for a good seal. Make sure to clean the cylinder head surface and the valve cover sealing surface thoroughly before installing the new gaskets.

When Things Go Wrong: Stripped Threads and Broken Bolts

Sometimes, despite our best efforts, things go wrong. Stripped threads and broken bolts are a reality of working on cars. If you strip a thread in the cylinder head, you have a few options:

Helicoil: A Helicoil is a thread repair insert that can be used to repair stripped threads. It's a cost-effective solution for minor thread damage.

Thread Tap: If the threads are only slightly damaged, you may be able to clean them up with a thread tap. Be careful not to remove too much material.

Oversized Bolt: In some cases, you may be able to use an oversized bolt to repair the stripped threads. However, this may require drilling and tapping the hole to the larger size.

If you break a bolt, you'll need to extract it. Bolt extractors are available, but sometimes welding a nut to the broken bolt is the easiest method. If the broken bolt is deep inside the head, consider having a professional handle the extraction.

Upgrading Valve Covers: Aftermarket Options

Many 350z owners choose to upgrade their valve covers for aesthetic or performance reasons. Aftermarket valve covers are available in various materials, such as aluminum and carbon fiber. Aluminum valve covers are often stronger and more durable than the original plastic ones, and they can also improve engine cooling. Carbon fiber valve covers are lightweight and offer a unique look.

When installing aftermarket valve covers, make sure to follow the manufacturer's instructions. The torque specs may be different from the factory specs. Also, pay attention to the gasket type. Some aftermarket valve covers use different gaskets than the OEM valve covers.

Final Thoughts

Properly torqueing your 350z valve covers is a crucial step in ensuring a reliable and leak-free engine. By understanding the importance of torque specs, using the right tools, following the correct procedure, and avoiding common mistakes, you can successfully tackle this task yourself. Always consult your factory service manual for the most accurate information and don't hesitate to seek professional help if you're unsure about any aspect of the procedure. Good luck!