3rd Gen 4runner Extended Sway Bar Links

The 3rd generation Toyota 4Runner (1996-2002) remains a beloved platform for off-roading and overland enthusiasts. Its solid rear axle, robust engine options, and relatively simple design make it a prime candidate for modifications aimed at improving its off-road prowess. One crucial area of enhancement often overlooked is the sway bar system, specifically the sway bar links. When lifting a 3rd gen 4Runner, the factory sway bar links become too short, limiting articulation and potentially causing damage. This necessitates the use of extended sway bar links. This article will delve into the technical specifications, engineering choices, real-world performance, and future trends of extended sway bar links for the 3rd gen 4Runner.

Technical Specifications and Engineering Choices

Factory sway bar links on the 3rd gen 4Runner are designed for the vehicle's stock ride height. Lifting the vehicle alters the geometry of the suspension system. The sway bar, designed to resist body roll, now operates at an extreme angle, hindering its effectiveness and putting undue stress on the links themselves. Extended sway bar links correct this geometry, restoring the sway bar to a more neutral position and allowing for increased suspension travel.

Length: The ideal length of extended sway bar links depends on the amount of lift applied to the vehicle. Generally, a 2-3 inch lift requires sway bar links that are 2-4 inches longer than stock. Manufacturers often provide recommendations based on the lift height. Accurate measurement of the stock length and the desired extended length is crucial.

Materials: Extended sway bar links are typically constructed from either steel or aluminum. Steel links offer superior strength and durability, making them suitable for heavy off-road use. Common steel alloys include 4140 chromoly steel, known for its high tensile strength and resistance to bending. Aluminum links, while lighter, are generally less robust and may be more susceptible to damage in extreme conditions. The choice depends on the intended use of the vehicle. Consider the trade-off between weight savings and overall strength.

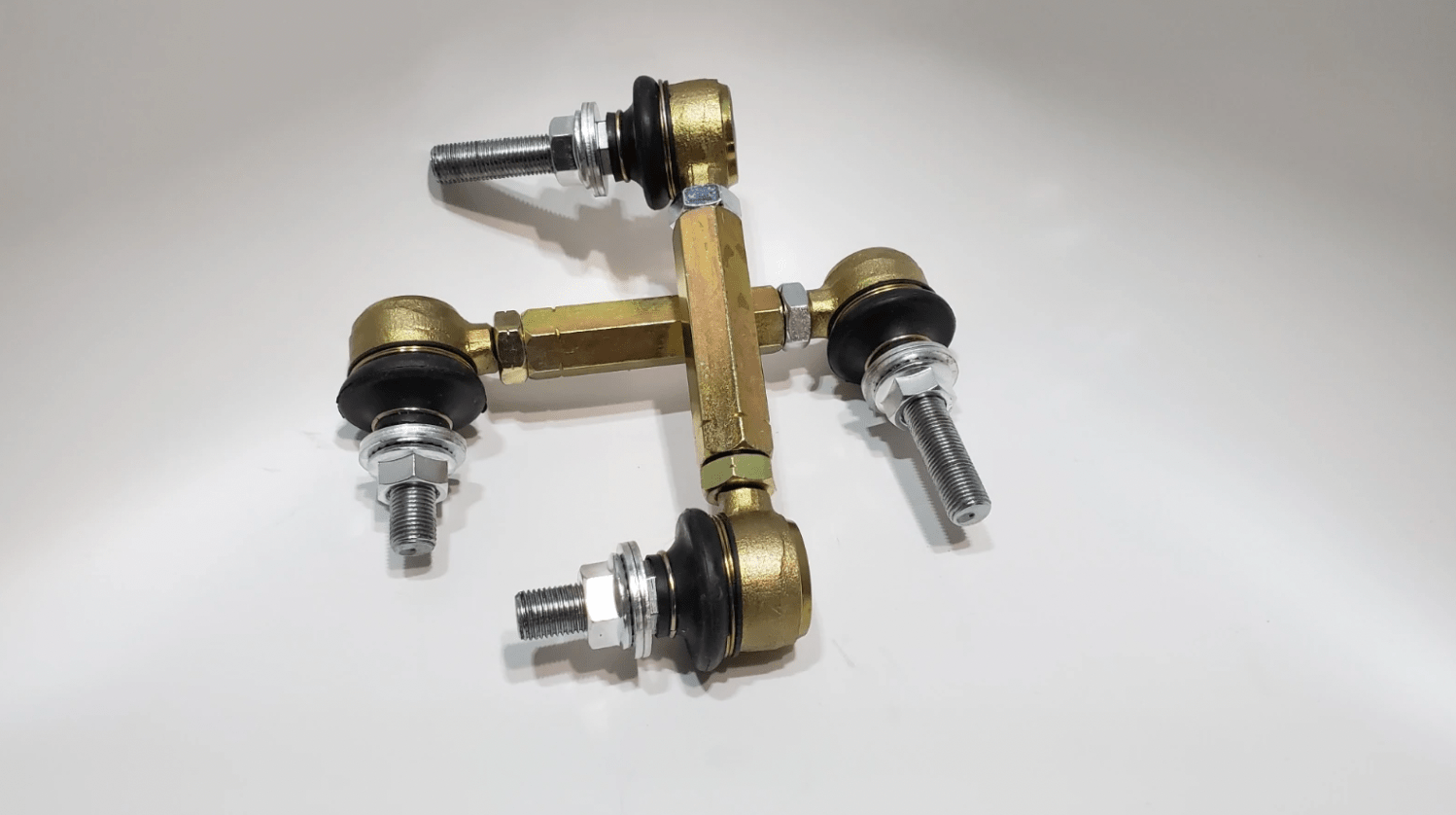

Construction: The design of the sway bar links varies. Some utilize a simple straight bar with threaded ends for attaching to the sway bar and the lower control arm. Others feature a more complex design with adjustable ends or heim joints. Heim joints offer greater articulation and reduce binding, which can be beneficial for maximizing off-road performance. However, they require regular maintenance and are more prone to wear and tear than traditional rubber bushings. The choice of bushing material (polyurethane vs. rubber) also impacts performance and durability. Polyurethane bushings are stiffer, providing a more direct feel and improved handling, but they can transmit more vibration and noise. Rubber bushings offer better vibration damping but less precise handling.

Adjustability: Some extended sway bar links offer adjustability, allowing for fine-tuning of the sway bar's preload. This can be useful for dialing in the vehicle's handling characteristics and compensating for variations in suspension setup.

Comparison with Alternatives

Alternatives to extended sway bar links include disconnecting the sway bar entirely or utilizing quick-disconnect sway bar links. Disconnecting the sway bar provides maximum articulation off-road but significantly reduces on-road stability and can be dangerous. Quick-disconnect links offer the best of both worlds, allowing for easy disconnection off-road and reconnection for on-road driving.

Pros of Extended Sway Bar Links:

- Relatively inexpensive

- Simple to install

- Restore proper sway bar geometry

- Improve on-road handling compared to disconnecting the sway bar

- Increase off-road articulation compared to stock links

Cons of Extended Sway Bar Links:

- Limited articulation compared to disconnecting the sway bar

- May still limit suspension travel in extreme situations

- Can be prone to bending or breaking under severe stress

Pros of Quick-Disconnect Sway Bar Links:

- Maximum articulation when disconnected

- Improved on-road handling when connected

- Versatile solution for both on- and off-road driving

Cons of Quick-Disconnect Sway Bar Links:

- More expensive than extended sway bar links

- Require manual disconnection and reconnection

- Additional maintenance required to prevent corrosion and binding

Real-World Performance

In real-world scenarios, extended sway bar links provide a noticeable improvement in both on- and off-road performance for lifted 3rd gen 4Runners. On-road, they help maintain stability and reduce body roll, improving handling and driver confidence. Off-road, they allow for greater suspension articulation, enabling the vehicle to navigate uneven terrain more effectively. However, it's important to remember that extended sway bar links are a compromise. They don't offer the same level of articulation as disconnecting the sway bar entirely, but they provide a significant improvement over stock links without sacrificing on-road handling.

Users often report improved ride quality and reduced stress on other suspension components after installing extended sway bar links. The corrected sway bar geometry reduces binding and allows the suspension to move more freely, resulting in a smoother and more controlled ride.

Reliability Aspects and Maintenance Tips

The reliability of extended sway bar links depends heavily on the quality of the materials and construction. Cheap, poorly made links are more likely to bend or break under stress. Investing in high-quality links from a reputable manufacturer is crucial for ensuring long-term reliability. Regular inspection of the sway bar links is essential. Check for signs of wear, such as cracks, bends, or loose connections. Pay close attention to the bushings, as these are a common wear point. Replace worn bushings promptly to prevent further damage to the links and other suspension components. If using heim joints, regular lubrication is necessary to prevent corrosion and binding. Use a high-quality grease specifically designed for heim joints. Periodically clean the threads of the sway bar links and apply anti-seize compound to prevent them from seizing.

Proper installation is also critical for reliability. Ensure that the links are properly torqued and that all hardware is securely fastened. Incorrect installation can lead to premature failure and potential damage to the vehicle.

Future Trends

The future of sway bar link technology for off-road vehicles is likely to focus on improved materials, advanced designs, and electronic control systems. We can expect to see greater use of lightweight, high-strength materials like carbon fiber and titanium in high-performance applications. Electronic sway bar disconnect systems, which allow for on-demand disconnection and reconnection of the sway bar at the touch of a button, are becoming increasingly popular and will likely become more affordable and accessible in the future. Adaptive sway bar systems, which automatically adjust the sway bar's stiffness based on driving conditions, are also under development and could offer significant improvements in both on- and off-road performance.

Furthermore, advancements in 3D printing technology could allow for the creation of custom sway bar links tailored to specific vehicle setups and driving styles. This could revolutionize the aftermarket suspension industry and allow for a new level of personalization and performance optimization.

Forward-Looking Note

The automotive industry is undergoing a rapid transformation, driven by advancements in technology, increasing environmental concerns, and evolving consumer preferences. Electric vehicles, autonomous driving systems, and connected car technologies are reshaping the way we think about transportation. While the 3rd gen 4Runner represents a simpler era of automotive engineering, the principles of suspension design and performance optimization remain relevant. As the industry continues to evolve, automotive professionals must stay abreast of the latest technologies and trends to remain competitive and provide innovative solutions to meet the changing needs of drivers. The continued development of advanced suspension components, like electronically controlled sway bars and adaptive dampers, will play a crucial role in enhancing the performance, safety, and efficiency of future vehicles, whether they are gasoline-powered, electric, or autonomous.