4 Cylinder With 8 Spark Plugs

Alright, let's dive into something a little less common but definitely intriguing: a 4-cylinder engine with 8 spark plugs. You've likely seen engines with one spark plug per cylinder, maybe even a few high-performance ones with two per cylinder. But why would someone go to the trouble of adding a second spark plug to each cylinder in a 4-cylinder engine? What are the benefits, and what are the drawbacks? We'll break it all down here, covering the technical aspects in a way that's hopefully easy to understand.

The Basic Concept: Redundancy and Combustion

At its core, the idea behind dual ignition, or having two spark plugs per cylinder, is about improving combustion efficiency and providing redundancy. In a standard engine, a single spark plug ignites the air-fuel mixture within the combustion chamber. The resulting flame front then spreads outwards, consuming the mixture. However, this process isn't always perfect.

Several factors can hinder complete combustion: uneven mixture distribution, suboptimal cylinder design, and the presence of 'quench areas' (cooler regions within the combustion chamber near the cylinder walls). These factors can lead to incomplete burning, resulting in reduced power, increased emissions, and potentially even engine knocking.

How Dual Ignition Helps

Adding a second spark plug aims to address these issues. By having two ignition points within the cylinder, the flame front can spread more rapidly and uniformly. Think of it like starting a campfire with two matches instead of one – the fire is likely to catch faster and burn more evenly. More specifically:

- Faster Flame Propagation: Two flame fronts meeting each other in the cylinder dramatically shorten the time it takes for the entire air/fuel mixture to be consumed. This is particularly beneficial at higher engine speeds (RPM) when the available combustion time is limited.

- Improved Combustion Efficiency: More complete combustion means more of the fuel's energy is converted into mechanical work, resulting in increased power and potentially better fuel economy.

- Reduced Knocking: By ensuring a more uniform burn, dual ignition can reduce the likelihood of detonation (knocking), which is caused by pockets of unburned air/fuel mixture spontaneously combusting due to pressure and heat. Detonation is extremely damaging to the engine.

- Lower Emissions: More complete combustion translates to fewer unburned hydrocarbons (HC) and carbon monoxide (CO) in the exhaust gases.

- Redundancy: If one spark plug fails, the other can (hopefully) keep the engine running, albeit with reduced performance. This is a backup system.

Technical Implementation

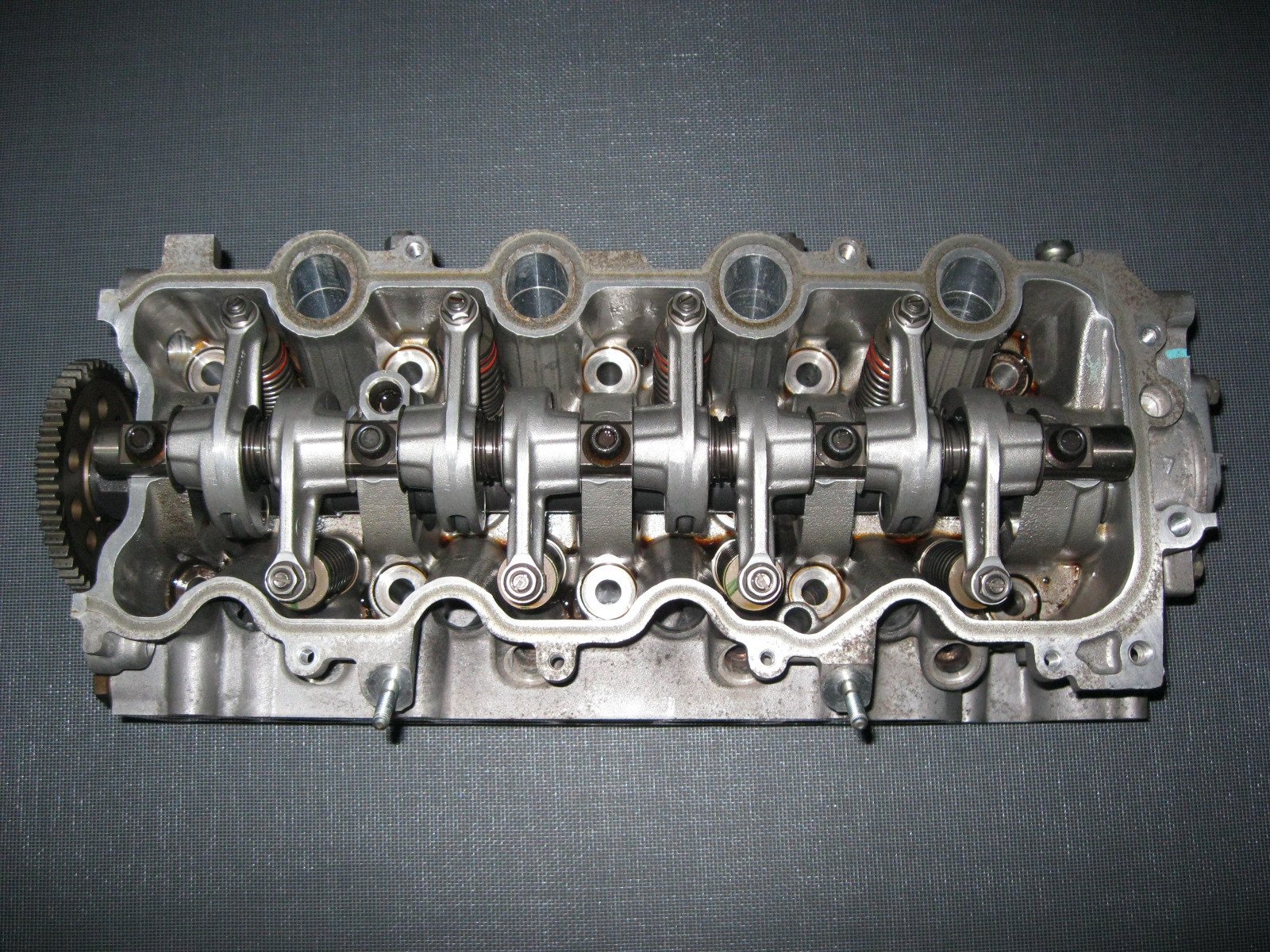

Implementing a dual-ignition system requires some significant modifications to the engine's cylinder head. This isn't just a simple "bolt-on" upgrade. Here's a breakdown:

Cylinder Head Design

The cylinder head needs to be specifically designed to accommodate two spark plugs per cylinder. This means:

- Spark Plug Bosses: Castings or machined features in the cylinder head to mount and seal the spark plugs. These need to be positioned strategically to optimize flame propagation. The angle and location of the spark plugs are critical.

- Cooling Passages: Adding a second spark plug generates more heat in the cylinder head, so cooling passages need to be carefully designed to prevent overheating.

- Valve Placement: The placement of intake and exhaust valves needs to be considered in conjunction with the spark plug locations. There needs to be enough space for everything.

- Combustion Chamber Shape: The shape of the combustion chamber itself will be affected by the presence of two spark plugs. The design needs to encourage rapid and complete combustion.

Ignition System

The ignition system needs to be able to independently fire eight spark plugs. This typically involves either:

- Dual Ignition Modules: Two separate ignition modules, each controlling four spark plugs. This is a common approach in older systems.

- Programmable Engine Management System (EMS): A modern programmable EMS can be configured to fire each spark plug individually, allowing for precise control over ignition timing. This is the preferred solution for high-performance applications.

The ignition timing for each spark plug can be identical, or it can be slightly offset. Offsetting the timing can further optimize combustion by creating a slightly staggered burn pattern. This is usually achieved through careful mapping of the ignition system within the EMS.

Spark Plug Selection

Choosing the right spark plugs is crucial. Factors to consider include:

- Heat Range: The spark plugs need to be of the correct heat range to dissipate heat effectively and prevent pre-ignition or fouling.

- Thread Size and Reach: The spark plugs need to physically fit into the cylinder head and have the correct reach to position the electrode within the combustion chamber.

- Electrode Material: Iridium or platinum spark plugs are generally preferred for their durability and consistent performance.

Advantages and Disadvantages

Let's weigh the pros and cons of a 4-cylinder engine with 8 spark plugs:

Advantages:

- Improved Performance: Increased power and torque, especially at higher RPM.

- Enhanced Fuel Efficiency: More complete combustion can lead to better fuel economy.

- Reduced Emissions: Lower levels of unburned hydrocarbons and carbon monoxide.

- Reduced Knocking: Less prone to detonation, allowing for higher compression ratios or more aggressive ignition timing.

- Redundancy: Increased reliability in the event of a spark plug failure.

Disadvantages:

- Complexity: Significantly more complex than a single-ignition system.

- Cost: The modifications to the cylinder head and ignition system can be expensive.

- Maintenance: Replacing eight spark plugs instead of four increases maintenance costs.

- Potential for Interference: Proper shielding and wiring are essential to prevent electromagnetic interference (EMI) from affecting other electronic components.

- Weight: The added components can increase engine weight slightly.

Real-World Examples

Dual ignition systems aren't exactly new. They've been used in various applications, often in situations where performance and reliability are paramount. Some notable examples include:

- Aircraft Engines: Many older aircraft engines used dual ignition for increased reliability. A single engine failure in flight can be catastrophic, so redundancy is crucial.

- Motorcycles: Some motorcycles, particularly those designed for racing or high-performance applications, have used dual ignition to improve combustion efficiency.

- Early Automotive Applications: Some early automobiles experimented with dual ignition, but it was often deemed too complex and expensive for mass production.

- Modified Engines: Enthusiasts often add dual ignition to heavily modified engines to maximize performance.

Is it Worth It?

So, is converting a standard 4-cylinder engine to a dual-ignition system worth the effort and expense? The answer largely depends on your specific goals and resources. For most everyday drivers, the benefits are likely outweighed by the complexity and cost. However, if you're building a high-performance engine for racing or other demanding applications, dual ignition can offer a significant performance boost.

Before undertaking such a project, carefully consider your budget, skill level, and the availability of suitable parts and expertise. You'll need a cylinder head that's either designed for dual ignition or can be modified to accommodate it. You'll also need a programmable EMS to control the ignition timing.

In conclusion, a 4-cylinder engine with 8 spark plugs is a fascinating example of how engineers can optimize combustion for improved performance. While it's not a common modification, it can be a worthwhile investment for those seeking to push the boundaries of engine technology. Just be prepared for the complexity and expense involved.

Disclaimer: Modifying an engine can void your warranty and may not be legal in all areas. Always consult with a qualified mechanic before undertaking any significant engine modifications.