7 Wire Trailer Wiring Harness

Understanding the 7-Wire Trailer Wiring Harness: A Comprehensive Guide

Towing a trailer opens up a world of possibilities, from hauling equipment for work to taking your boat out for a weekend adventure. However, connecting your trailer safely and legally requires a reliable wiring system. The 7-wire trailer wiring harness is a common and versatile solution, offering a comprehensive set of electrical connections for various trailer functions. This guide provides a detailed overview of the 7-wire harness, its functions, wiring configurations, and troubleshooting tips.

What is a 7-Wire Trailer Wiring Harness?

A 7-wire trailer wiring harness is a standardized cable and connector system designed to provide electrical power and control signals between a tow vehicle and a trailer. It consists of seven individual wires, each dedicated to a specific function, encased in a protective sheath. The 7-way connector plugs into a corresponding socket on the tow vehicle, establishing a secure and reliable electrical connection.

Unlike simpler 4-way flat connectors primarily used for basic lighting, the 7-wire harness offers additional capabilities crucial for larger and more complex trailers. These include functionalities like electric brakes, auxiliary power, and reverse lights. This makes it suitable for a wider range of trailers, including travel trailers, boat trailers, and utility trailers equipped with these advanced features.

Functions of the 7 Wires

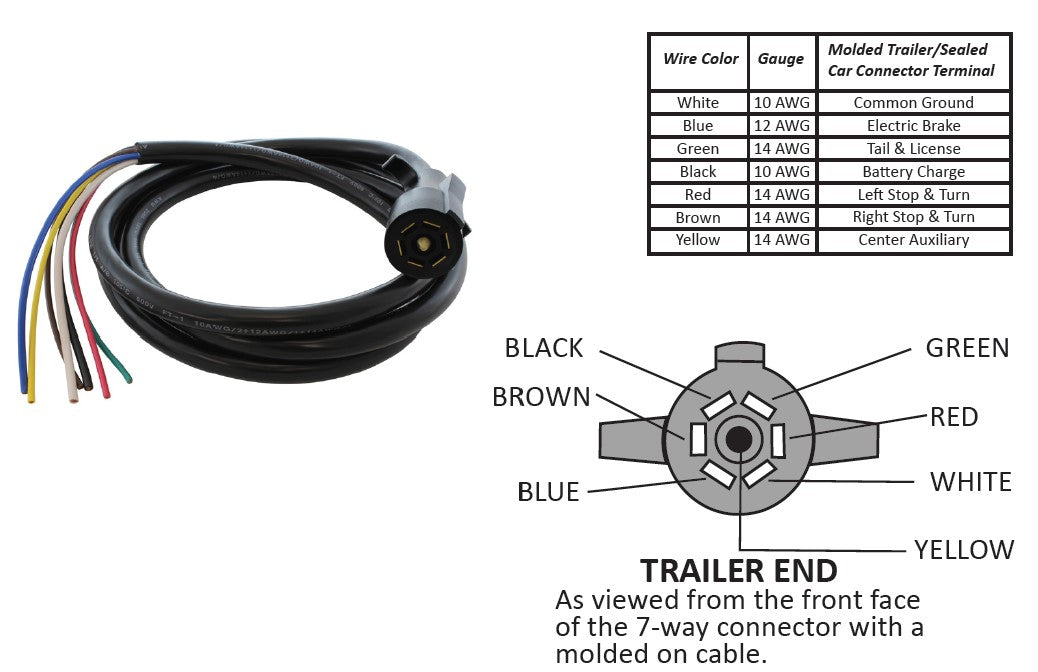

Each wire in the 7-wire harness plays a critical role. Understanding these functions is essential for proper installation and troubleshooting. Here's a breakdown of each wire and its corresponding purpose:

- Ground Wire (White): The white wire serves as the common ground for all electrical circuits in the trailer. A proper ground connection is crucial for the entire wiring system to function correctly. Poor grounding can lead to erratic lighting, brake malfunctions, and other electrical problems. Always ensure a secure and clean connection to the trailer frame.

- Tail Lights/Running Lights (Brown): This wire activates the trailer's tail lights and running lights whenever the tow vehicle's headlights are turned on. These lights are essential for visibility and are legally required.

- Left Turn Signal/Stop Light (Yellow): The yellow wire controls the left turn signal and brake light on the trailer. It receives signals from the tow vehicle's turn signal and brake light circuits.

- Right Turn Signal/Stop Light (Green): Similar to the yellow wire, the green wire controls the right turn signal and brake light on the trailer.

- Electric Brakes (Blue): The blue wire is dedicated to controlling the trailer's electric brakes. It connects to the brake controller in the tow vehicle, allowing the driver to proportionally apply the trailer brakes based on the tow vehicle's braking force. Electric brakes are essential for safely stopping heavier trailers.

- Reverse Lights (Black): This wire activates the trailer's reverse lights when the tow vehicle is shifted into reverse. These lights provide additional visibility when backing up and alert other drivers to your intentions.

- Auxiliary Power (Red): The red wire provides a constant 12V power supply from the tow vehicle to the trailer. This power can be used to charge a trailer battery, operate interior lights, or power other electrical appliances in the trailer. Note that this wire may not be powered continuously in all vehicles, and a relay or additional wiring may be required to ensure constant power.

Wiring Configurations and Color Codes

While the wire functions are standardized, the color coding can sometimes vary slightly between manufacturers. It's crucial to verify the wire functions using a multimeter or circuit tester before making any connections. However, the above color scheme is the most common and widely accepted standard.

When wiring a 7-way connector, it's essential to follow a wiring diagram carefully. Diagrams are readily available online and often included with the wiring harness. Incorrect wiring can lead to serious electrical problems and potential safety hazards. Always double-check your connections before testing the system.

Installation Tips and Considerations

Installing a 7-wire trailer wiring harness can be a DIY project for experienced individuals, but it's often recommended to have it professionally installed, especially if you're not comfortable working with electrical systems. Here are some important tips to keep in mind during installation:

- Choose the Right Harness: Ensure the harness you select is compatible with your tow vehicle and trailer. Consider the trailer's features and electrical requirements when choosing a harness.

- Use Quality Connectors: Invest in high-quality connectors that are weather-resistant and corrosion-resistant. This will ensure a reliable and long-lasting connection.

- Proper Wire Routing: Route the wires carefully, avoiding sharp edges, moving parts, and exhaust components. Secure the wires with zip ties or clamps to prevent them from rubbing or chafing.

- Secure Connections: Make sure all connections are tight and secure. Use crimp connectors or solder and heat shrink tubing for reliable connections.

- Test the System: After completing the installation, thoroughly test all the functions of the harness, including the lights, brakes, and auxiliary power. Use a trailer tester or have someone help you check each function.

Troubleshooting Common Issues

Even with careful installation, problems can sometimes arise with a 7-wire trailer wiring harness. Here are some common issues and troubleshooting tips:

- Lights Not Working: Check the bulbs, fuses, and connections. Use a multimeter to check for voltage at the connector. A bad ground is often the culprit.

- Brakes Not Working: Check the brake controller settings and wiring. Inspect the trailer brake magnets for damage. A faulty brake controller can also cause brake problems.

- Intermittent Problems: Loose connections or corroded terminals can cause intermittent problems. Clean and tighten all connections.

- Short Circuits: A short circuit can blow fuses and cause damage to the wiring. Inspect the wiring for damage or exposed wires.

If you're experiencing persistent electrical problems with your trailer wiring, it's best to consult a qualified electrician or trailer repair technician. They have the expertise and tools to diagnose and repair complex electrical issues safely and effectively.

Maintenance and Care

To ensure the longevity and reliability of your 7-wire trailer wiring harness, regular maintenance is essential. Here are some tips for maintaining your harness:

- Inspect Regularly: Periodically inspect the harness for damage, wear, and corrosion. Check the connectors for loose connections or corrosion.

- Clean Connections: Clean the connectors with a wire brush or electrical contact cleaner to remove dirt and corrosion.

- Apply Dielectric Grease: Apply dielectric grease to the connectors to protect them from moisture and corrosion.

- Store Properly: When the trailer is not in use, store the harness in a dry and protected location to prevent damage.

Investing in a 7-wire trailer wiring harness is a worthwhile investment for anyone who tows a trailer with electric brakes or other advanced features. By understanding the functions of each wire, following proper installation procedures, and performing regular maintenance, you can ensure a safe and reliable towing experience for years to come. Remember to always prioritize safety and consult a professional if you're unsure about any aspect of the wiring process.