Ac Low Side Pressure To High

The air conditioning (AC) system in a modern vehicle is a complex thermodynamic system, crucial for occupant comfort and safety. A key indicator of system health and performance is the low-side pressure, which, under normal operating conditions, should be significantly lower than the high-side pressure. However, instances of low-side pressure creeping towards, or even exceeding, the high-side pressure point to significant underlying issues within the AC system. This article will delve into the technical aspects, engineering choices, real-world performance, alternatives, and future trends related to AC systems experiencing this problematic pressure equalization.

Understanding Normal AC System Operation

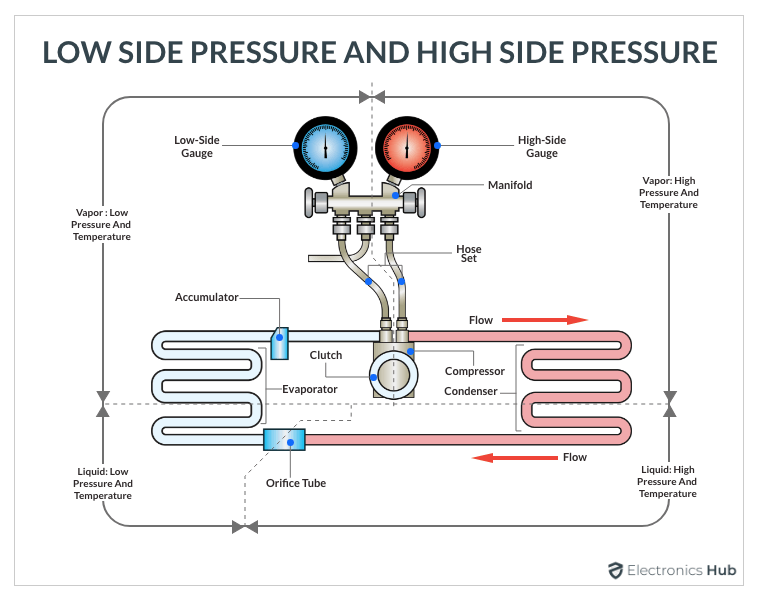

Before analyzing the aberrant behavior, it's essential to understand the standard operating cycle of a vehicle's AC system. The system comprises several key components:

- Compressor: Pressurizes the refrigerant, increasing its temperature and sending it to the condenser.

- Condenser: Dissipates heat from the high-pressure refrigerant, causing it to condense into a liquid.

- Expansion Valve/Orifice Tube: Reduces the pressure and temperature of the liquid refrigerant before it enters the evaporator.

- Evaporator: Absorbs heat from the passenger compartment, causing the refrigerant to boil and evaporate into a low-pressure gas.

- Accumulator/Receiver Drier: Removes moisture and debris from the refrigerant.

During normal operation, the low-side pressure, measured after the evaporator, indicates the suction pressure of the compressor. A significantly lower pressure here ensures the refrigerant absorbs heat effectively in the evaporator. The high-side pressure, measured after the compressor, reflects the discharge pressure and indicates the system's ability to reject heat at the condenser. A healthy pressure differential is critical for efficient cooling.

Causes of Low-Side Pressure Approaching High-Side Pressure

When the low-side pressure rises to meet or exceed the high-side pressure, the cooling capacity diminishes or vanishes entirely. Several factors can contribute to this condition:

Compressor Issues

The compressor is the heart of the AC system. A failing or worn-out compressor is the most common culprit. Internal leakage, such as worn piston rings or a faulty reed valve, can allow high-pressure refrigerant to bleed into the low-pressure side, equalizing the pressures. Conversely, a completely seized compressor will prevent any pressure differential.

Diagnosis: Observe pressure readings during compressor engagement. Lack of pressure change or unusual noises indicate compressor failure. Perform a compressor efficiency test using specialized gauges and measuring the temperature differential across the evaporator and condenser.

Expansion Valve/Orifice Tube Problems

A clogged or restricted expansion valve or orifice tube can impede refrigerant flow to the evaporator. While this might initially result in lower-than-normal low-side pressure, the reduced flow eventually leads to equalization when the compressor continues to run and build high-side pressure while the low-side pressure rises due to lack of refrigerant demand.

Diagnosis: Inspect the expansion valve/orifice tube for debris. Monitor the temperature of the line leading to the evaporator; a significantly colder line than expected might indicate a restriction. Pressure drop testing across the component can also confirm a blockage.

Blockage in the System

Any blockage in the system, whether in the lines, condenser, or evaporator, can restrict refrigerant flow and lead to pressure equalization. Blockages often result from contaminants, such as metal particles from a failing compressor or sealant introduced improperly.

Diagnosis: Visually inspect lines for kinks or damage. Use a thermal imaging camera to identify temperature variations along the refrigerant lines, which can indicate blockages. A flush of the system might be necessary after replacing any major component.

Overcharging the System

Adding too much refrigerant to the system increases both low-side and high-side pressures. An overcharged system cannot efficiently reject heat at the condenser, leading to elevated pressures throughout.

Diagnosis: Verify the refrigerant charge using a manifold gauge set and compare the readings to the vehicle's specifications (typically found on a sticker under the hood). Recover excess refrigerant to the correct level.

Contaminated Refrigerant

Moisture or non-condensable gases in the refrigerant can reduce cooling efficiency and increase system pressures. Moisture, in particular, can react with the refrigerant to form corrosive acids, damaging components.

Diagnosis: Use a refrigerant identifier to check for contaminants. Recover and replace contaminated refrigerant. Consider evacuating the system for an extended period to remove moisture. Replace the receiver drier or accumulator.

Condenser Issues

If the condenser is heavily obstructed with debris, or if its cooling fan isn't functioning correctly, the high-side pressure can rise excessively. This excessive high-side pressure can eventually lead to a corresponding increase in the low-side pressure as the system struggles to maintain the proper pressure differential.

Diagnosis: Inspect the condenser fins for blockage. Verify the operation of the condenser fan. Check for proper airflow through the condenser.

Alternative Solutions and Engineering Choices

Several engineering choices influence the susceptibility of an AC system to pressure equalization. For example, the type of expansion device (TXV vs. orifice tube) plays a role. A TXV (Thermal Expansion Valve) is generally more efficient at regulating refrigerant flow and can better handle varying loads, potentially preventing the low-side pressure from rising as quickly as it might with an orifice tube system under certain fault conditions.

TXV (Thermal Expansion Valve) Systems:

- Pros: More precise refrigerant flow control, better cooling performance under varying loads, less susceptible to icing.

- Cons: More complex and expensive, more prone to failure due to intricate internal mechanisms.

Orifice Tube Systems:

- Pros: Simpler and less expensive, fewer moving parts, potentially more reliable in some aspects.

- Cons: Less precise refrigerant flow control, less efficient cooling under varying loads, more susceptible to icing.

Variable displacement compressors are another engineering choice that can affect system performance. These compressors adjust their output based on cooling demand, which can improve efficiency and reduce the likelihood of pressure imbalances compared to fixed displacement compressors, especially when facing a partial blockage or refrigerant leak.

Real-World Performance and Reliability

In real-world conditions, several factors can accelerate the degradation of AC system components and increase the likelihood of pressure equalization. These include:

- Environmental Factors: Road salt, debris, and extreme temperatures can corrode components and restrict airflow.

- Driving Habits: Frequent short trips and extended idling can strain the compressor.

- Maintenance Neglect: Failure to replace the cabin air filter can restrict airflow to the evaporator, reducing cooling efficiency and potentially contributing to pressure imbalances.

Reliability hinges on proper maintenance and timely repairs. Addressing minor issues promptly can prevent them from escalating into more significant problems that lead to pressure equalization. Using high-quality replacement parts and following OEM procedures during repairs are also crucial for ensuring long-term system reliability.

Maintenance Tips for Automotive Professionals

Preventative maintenance is key to minimizing the risk of AC system failures. Here are some tips for automotive professionals:

- Regular Inspections: Check refrigerant levels, compressor operation, and condenser fan function during routine maintenance.

- Pressure Testing: Monitor both low-side and high-side pressures to identify potential issues early.

- Leak Detection: Use electronic leak detectors or UV dye to identify refrigerant leaks.

- System Flushing: Flush the system after compressor failures to remove debris and contaminants.

- Filter Replacement: Replace the cabin air filter regularly to ensure proper airflow.

- Refrigerant Handling: Use proper recovery and charging equipment to prevent contamination and ensure accurate refrigerant levels.

- Educate Customers: Inform customers about the importance of AC system maintenance and the potential consequences of neglect.

Future Trends

The automotive industry is undergoing significant changes, and AC systems are evolving as well. Future trends include:

- Electric Compressors: As electric vehicles become more prevalent, electric compressors powered by the vehicle's battery will replace traditional belt-driven compressors.

- R-1234yf Refrigerant: This refrigerant has a lower global warming potential (GWP) than R-134a and is becoming increasingly common in new vehicles.

- CO2 Refrigerant (R-744): CO2 is a natural refrigerant with an extremely low GWP, and it's being explored as a potential replacement for R-1234yf in some applications.

- Improved System Efficiency: Automakers are constantly seeking ways to improve AC system efficiency to reduce energy consumption and emissions. This includes advancements in compressor technology, heat exchangers, and control systems.

- Integrated Thermal Management: Future vehicles will likely feature more integrated thermal management systems that control the temperature of the battery, powertrain, and cabin using a unified approach.

Conclusion

Understanding the causes of low-side pressure approaching high-side pressure in automotive AC systems is critical for accurate diagnosis and effective repairs. By adhering to best practices for maintenance and repair, automotive professionals can ensure the reliable operation of these systems and provide optimal comfort for vehicle occupants. As the automotive industry continues to evolve, staying abreast of new technologies and refrigerants will be essential for maintaining expertise in AC system service.