Adhesion Promoter Before Or After Primer

Adhesion Promoter Before Or After Primer: The Definitive Guide

Achieving a flawless and long-lasting finish on any project, be it automotive painting, home improvement, or crafting, often hinges on proper surface preparation. Two key players in this preparation are adhesion promoters and primers. Understanding the difference between them, and more importantly, the correct order of application, is crucial for success. This article provides a clear, neutral, and helpful guide to answer the common question: Should you apply adhesion promoter before or after primer?

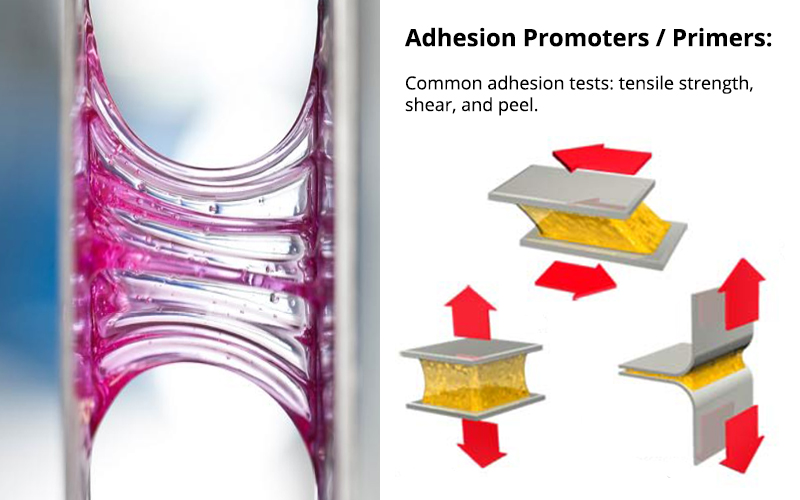

What is an Adhesion Promoter?

An adhesion promoter, sometimes referred to as a bonding agent, is a specialized coating designed to enhance the bond between a substrate (the surface you're painting or coating) and the subsequent layers of paint, primer, or adhesives. It's particularly vital when working with surfaces that are inherently difficult to bond to, such as:

- Plastics: Many types of plastic, like polypropylene and polyethylene, have a naturally slick surface that paint struggles to adhere to.

- Metals: Certain metals, especially non-ferrous ones like aluminum and galvanized steel, can oxidize and form a protective layer that hinders adhesion.

- Glass: Glass presents a smooth, non-porous surface that requires special treatment for coatings to properly grip.

- Powder-Coated Surfaces: When applying new paint over existing powder coating, an adhesion promoter ensures a strong bond.

Think of an adhesion promoter as a "glue" that bridges the gap between a difficult-to-bond-to surface and the primer or paint. It creates a more receptive surface for the subsequent layers, preventing chipping, peeling, and other adhesion failures.

What is Primer?

Primer is a preparatory coating applied to a surface before painting. Its primary functions include:

- Creating a Uniform Surface: Primer helps to even out surface imperfections, such as minor scratches, dents, and variations in texture.

- Sealing Porous Surfaces: Porous materials like wood and drywall can absorb paint unevenly, leading to inconsistent color and sheen. Primer seals these pores, preventing excessive paint absorption.

- Improving Paint Adhesion: While primer does improve adhesion, its primary function is to prepare the surface for optimal paint adhesion. It creates a more receptive and uniform base for the topcoat.

- Blocking Stains: Stain-blocking primers prevent stains like watermarks, grease, and smoke from bleeding through the topcoat.

- Enhancing Color Uniformity: Primers can be tinted to closely match the topcoat color, which helps achieve better color coverage and uniformity, especially when painting over dark or heavily colored surfaces.

In essence, primer creates the ideal foundation for a beautiful and durable paint job. It’s the intermediary layer that ensures the topcoat adheres properly, looks its best, and lasts longer.

The Crucial Question: Adhesion Promoter Before or After Primer?

The answer is almost always: Adhesion promoter before primer.

Here’s the rationale:

- Direct Contact with the Substrate: An adhesion promoter is designed to bond directly to the bare substrate. It needs to make direct contact with the surface it's trying to promote adhesion to. If you apply primer first, you're essentially asking the adhesion promoter to bond to the primer, not the underlying difficult-to-bond-to material. This defeats its purpose.

- Creating a Receptive Surface for Primer: The adhesion promoter modifies the surface characteristics of the substrate, making it more receptive to subsequent coatings, including the primer. It creates a chemical or physical bond that the primer can then latch onto.

- Optimizing the Bonding Process: By applying the adhesion promoter first, you are preparing the substrate itself for a strong bond. The primer then bonds to the now-modified substrate, and the paint bonds to the primer. This multi-layered approach ensures maximum adhesion and durability.

In summary: Think of it this way: Adhesion promoter tackles the inherent bonding problem of the substrate, while primer prepares a good surface for the paint.

When Might the Order Be Different? (Rare Exceptions)

While the rule of thumb is always adhesion promoter before primer, there might be *very* rare exceptions, and these are usually dictated by specific product instructions.

- Specific Product Instructions: Always, *always* consult the manufacturer's instructions for both the adhesion promoter and the primer you're using. Some products may have unique application requirements. If the manufacturer explicitly states otherwise, follow their guidance.

- Self-Etching Primers: Some self-etching primers contain etching agents that lightly abrade the surface to promote adhesion. In these cases, the primer *may* be sufficient, and a separate adhesion promoter might not be necessary (though, again, check the product data sheets).

It's crucial to reiterate that deviating from the standard order should only be done when explicitly instructed by the product manufacturer.

Step-by-Step Guide: Applying Adhesion Promoter and Primer Correctly

Here's a general step-by-step guide to ensure proper application:

- Surface Preparation: This is the most critical step. Clean the surface thoroughly to remove any dirt, grease, oil, wax, or contaminants. Use appropriate cleaners and degreasers based on the substrate material. Sanding the surface lightly can also help create a better mechanical bond.

- Apply Adhesion Promoter: Apply a thin, even coat of adhesion promoter according to the manufacturer's instructions. Allow it to dry completely. Drying times can vary, so refer to the product data sheet. Do not apply too thick of a coat.

- Apply Primer: Once the adhesion promoter is fully dry, apply a coat of primer. Choose a primer that is compatible with both the adhesion promoter and the topcoat you plan to use. Apply the primer in thin, even coats, allowing each coat to dry thoroughly before applying the next.

- Apply Topcoat (Paint): After the primer is completely dry, you can apply your topcoat (paint). Follow the manufacturer's instructions for the paint application.

Tips for Success

- Read the Data Sheets: This cannot be stressed enough. Always read and understand the technical data sheets for all products you are using (adhesion promoter, primer, and topcoat).

- Test a Small Area: Before applying to the entire project, test the adhesion promoter and primer on a small, inconspicuous area to ensure compatibility and proper adhesion.

- Proper Ventilation: Ensure adequate ventilation when working with adhesion promoters and primers, as they often contain solvents.

- Use Appropriate Safety Gear: Wear appropriate safety gear, such as gloves, eye protection, and a respirator, as needed.

- Avoid Contamination: Prevent contamination of the adhesion promoter and primer by using clean application tools and containers.

- Follow Drying Times: Strictly adhere to the recommended drying times for each product. Rushing the process can lead to adhesion failures.

Choosing the Right Adhesion Promoter and Primer

Selecting the right adhesion promoter and primer is crucial for success. Consider the following factors:

- Substrate Material: Choose an adhesion promoter and primer specifically designed for the substrate you're working with (e.g., plastic, metal, wood).

- Compatibility: Ensure that the adhesion promoter, primer, and topcoat are compatible with each other. Incompatible products can lead to adhesion problems and other finish defects.

- Environmental Conditions: Consider the environmental conditions in which the project will be exposed. Choose products that are resistant to moisture, UV light, and other environmental factors as needed.

- VOC Content: Be mindful of the Volatile Organic Compound (VOC) content of the products you choose, especially if you are working indoors or in areas with strict VOC regulations.

Conclusion

In the vast majority of cases, the correct order is adhesion promoter before primer. By understanding the roles of each product and following proper application techniques, you can achieve a durable, long-lasting, and professional-looking finish. Remember to always read and follow the manufacturer's instructions and test a small area before applying to the entire project. A little extra preparation goes a long way in ensuring a successful outcome and avoiding costly rework.