Air Conditioner Clutch Turns On And Off

Okay, let's talk about a common AC system issue: the air conditioner clutch turning on and off repeatedly, a phenomenon often referred to as "cycling" or "short-cycling." It can be a real pain, especially on a hot day, leaving you wondering why your car’s AC isn't blowing cold consistently. As an experienced DIYer, you probably already know the basics, but let’s dive deep into the potential causes, diagnostic steps, and possible solutions.

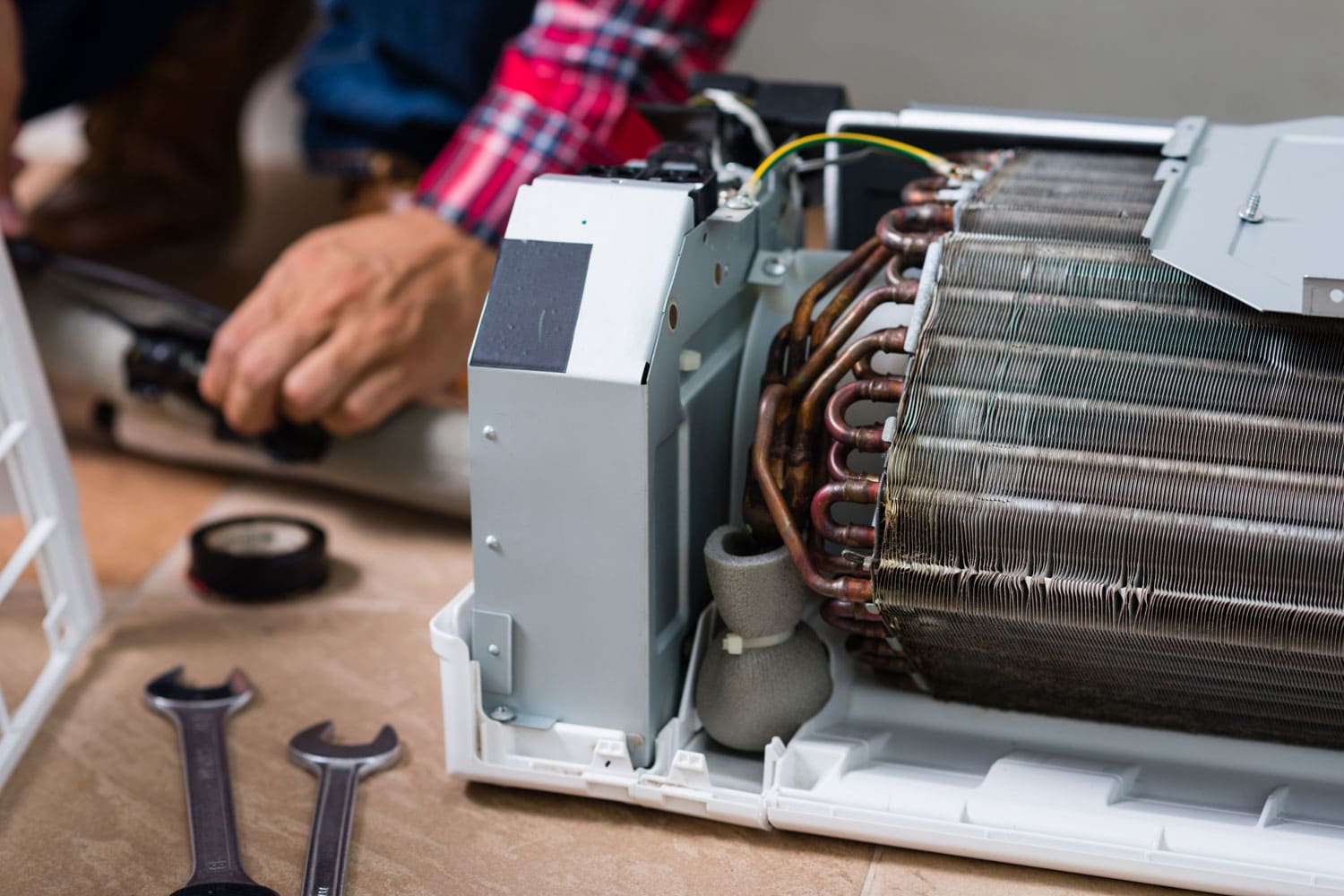

Understanding the AC Clutch

First, let's quickly review what the AC clutch does. The AC clutch is an electromagnetic device that connects the engine's crankshaft pulley to the AC compressor. When you turn on your AC, an electrical current is sent to the clutch, energizing an electromagnet. This electromagnet pulls the clutch plate towards the compressor pulley, effectively engaging the compressor. The compressor then circulates the refrigerant throughout the AC system, enabling the cooling process. When the AC is turned off, or when certain conditions are met (like low refrigerant pressure), the electrical current is cut, the electromagnet de-energizes, and the clutch disengages, stopping the compressor. Think of it like a switch that selectively powers the AC compressor.

Common Causes of AC Clutch Cycling

Now, why would this switch be turning on and off rapidly? There are several reasons, and pinpointing the exact cause requires a systematic approach.

1. Low Refrigerant Charge

This is by far the most common culprit. Refrigerant, such as R-134a or R-1234yf (check your vehicle's specifications), is the lifeblood of your AC system. When the refrigerant level is low, the system's low-pressure switch detects this and signals the AC clutch to disengage to protect the compressor from damage. The low-pressure switch is a safety device that prevents the compressor from running without adequate refrigerant lubrication. It's typically located on the suction (low-pressure) side of the AC system. After the clutch disengages, the pressure might rise slightly, causing the switch to re-engage the clutch briefly, creating the cycling effect. It's a vicious cycle! This protects the compressor, but means intermittent or no cooling.

Diagnosis: Use an AC manifold gauge set to check the high-side and low-side pressures of the system. Refer to your vehicle's service manual for the correct pressure readings. A significant difference from the specified range, especially a low reading on the low side, indicates a low refrigerant charge. You can also use a refrigerant leak detector to try and pinpoint the leak.

2. High Head Pressure

On the opposite end of the spectrum, excessive pressure on the high side of the system, also known as high head pressure, can also cause clutch cycling. The high-pressure switch, another safety device, will disengage the clutch to prevent damage to the compressor and other components if the pressure gets too high. This can be caused by:

- A clogged condenser: The condenser is like the radiator for your AC system. It dissipates heat from the refrigerant. If it's clogged with debris (leaves, bugs, etc.), it can't efficiently cool the refrigerant, leading to high pressure.

- Overcharging the system: Too much refrigerant can also cause excessive pressure. This is why it's crucial to add refrigerant carefully and accurately.

- A failing cooling fan: If the cooling fan that sits in front of the condenser isn't working properly, it can't draw enough air across the condenser coils, leading to overheating and high pressure.

- Contamination in the system: Moisture or non-condensable gases (like air) in the system can also contribute to high head pressure.

- A faulty expansion valve: The expansion valve controls the flow of refrigerant into the evaporator. If it's malfunctioning and restricting flow, it can cause pressure to build up on the high side.

Diagnosis: Again, use your manifold gauge set. High head pressure will be evident. Inspect the condenser for debris. Check the cooling fan for proper operation (it should run when the AC is turned on). If the pressure is excessively high even with a clean condenser and a functional fan, consider the possibility of overcharging or contamination, and consult a professional.

3. Faulty Low-Pressure or High-Pressure Switch

Sometimes, the switches themselves can be the problem. A faulty low-pressure switch might be falsely signaling low refrigerant even when the charge is adequate. Conversely, a faulty high-pressure switch might be incorrectly detecting high pressure. This can cause intermittent or erratic clutch cycling.

Diagnosis: The best way to diagnose a faulty switch is to bypass it temporarily (never do this permanently!). Consult your vehicle's wiring diagram to identify the switch's wires. Carefully disconnect the wires and use a jumper wire to connect them together. If the AC clutch stops cycling when the switch is bypassed, it indicates that the switch is likely faulty and needs to be replaced. Important: Monitor the system closely while the switch is bypassed to avoid compressor damage. Only bypass for short diagnostic periods. Use a multimeter to check for continuity. A good switch will have continuity when the system is in the appropriate pressure range.

4. Air Gap Issues

The air gap is the space between the clutch plate and the compressor pulley when the AC is off. If this gap is too large, the electromagnet might not be strong enough to consistently pull the clutch plate in, leading to slippage and eventual disengagement. Conversely, if the air gap is too small, the clutch might drag even when the AC is off, causing wear and tear.

Diagnosis: Use a feeler gauge to measure the air gap. The correct specification varies depending on the vehicle and compressor model, so consult your service manual. If the air gap is out of spec, you may be able to adjust it by removing or adding shims behind the clutch plate. If the clutch is worn, the only fix is to replace the clutch assembly, or the whole compressor if required.

5. Electrical Problems

Electrical issues can also cause the AC clutch to cycle. These could include:

- A faulty AC relay: The AC relay controls the power to the AC clutch. A failing relay might provide intermittent power, causing the clutch to cycle.

- Wiring problems: Damaged or corroded wiring, loose connections, or shorts in the wiring harness can disrupt the electrical signal to the clutch.

- A failing climate control module: The climate control module controls the AC system. A faulty module might send incorrect signals to the clutch.

- A weak ground: A poor ground connection for the AC system can cause erratic electrical behavior.

Diagnosis: Start by checking the AC relay. Swap it with a known good relay (like the horn relay) and see if the problem goes away. Inspect the wiring harness for damage or corrosion. Use a multimeter to check for voltage at the AC clutch connector when the AC is turned on. Ensure a good ground connection for the AC system. Consult your vehicle's wiring diagram for specific testing procedures.

6. Icing of the Evaporator Core

While less common, under certain conditions, the evaporator core (the part that cools the air inside the cabin) can ice up. This often happens when the ambient temperature is low but the humidity is high. The ice restricts airflow, reducing cooling efficiency. Some vehicles have an evaporator temperature sensor that will shut off the compressor to prevent icing. Once the ice melts, the compressor kicks back on, leading to cycling. You may also notice reduced airflow from the vents.

Diagnosis: Check the evaporator drain tube to ensure it's not clogged. Clogged drain tubes prevent condensation from escaping, contributing to icing. Consider reducing the AC blower fan speed to give the evaporator more time to warm up. This is more of a symptom related to a failing thermistor or the evaporator sensor.

Troubleshooting Steps

Here's a step-by-step approach to diagnosing AC clutch cycling:

- Visual Inspection: Start with a visual inspection. Check the condenser for debris, inspect the wiring harness for damage, and look for signs of refrigerant leaks (oily residue).

- Check Refrigerant Pressures: Use your manifold gauge set to check the high-side and low-side pressures. Compare the readings to the specifications in your service manual.

- Test the Switches: If the pressures seem normal, test the low-pressure and high-pressure switches by temporarily bypassing them.

- Measure the Air Gap: Check the air gap between the clutch plate and the compressor pulley.

- Check Electrical Components: Test the AC relay, inspect the wiring harness, and check for voltage at the AC clutch connector.

- Scan for Codes: Use an OBD-II scanner to check for any trouble codes related to the AC system.

Final Thoughts

Diagnosing AC clutch cycling can be tricky, but by following a systematic approach and understanding the underlying principles, you can often pinpoint the problem yourself. Remember to consult your vehicle's service manual for specific procedures and specifications. If you're uncomfortable working on the AC system, or if you suspect a serious problem like a compressor failure, it's always best to consult a qualified technician. And remember, working with refrigerants requires proper certification and equipment, so be sure to follow all safety precautions. Good luck!