Auto Air Conditioning Pressure Readings

Understanding your vehicle's air conditioning (A/C) system pressure readings is crucial for diagnosing problems and ensuring optimal cooling performance. This article delves into the intricacies of A/C pressure readings, covering normal ranges, interpreting abnormal readings, and troubleshooting common A/C issues.

Understanding A/C System Basics

Before diving into pressure readings, a quick refresher on the A/C system is essential. The core components include the compressor, which circulates the refrigerant; the condenser, where high-pressure refrigerant cools and condenses into a liquid; the expansion valve or orifice tube, which meters the refrigerant flow and creates a pressure drop; and the evaporator, where the low-pressure refrigerant absorbs heat from the cabin air and evaporates back into a gas. Refrigerant, such as R-134a or the newer R-1234yf, is the lifeblood of the system.

The entire system operates on the principles of thermodynamics. The compressor increases the refrigerant's pressure and temperature. As it flows through the condenser, the heat dissipates. The expansion device then lowers the pressure and temperature dramatically, allowing the refrigerant to absorb heat in the evaporator. This cycle repeats continuously.

Typical A/C Pressure Readings

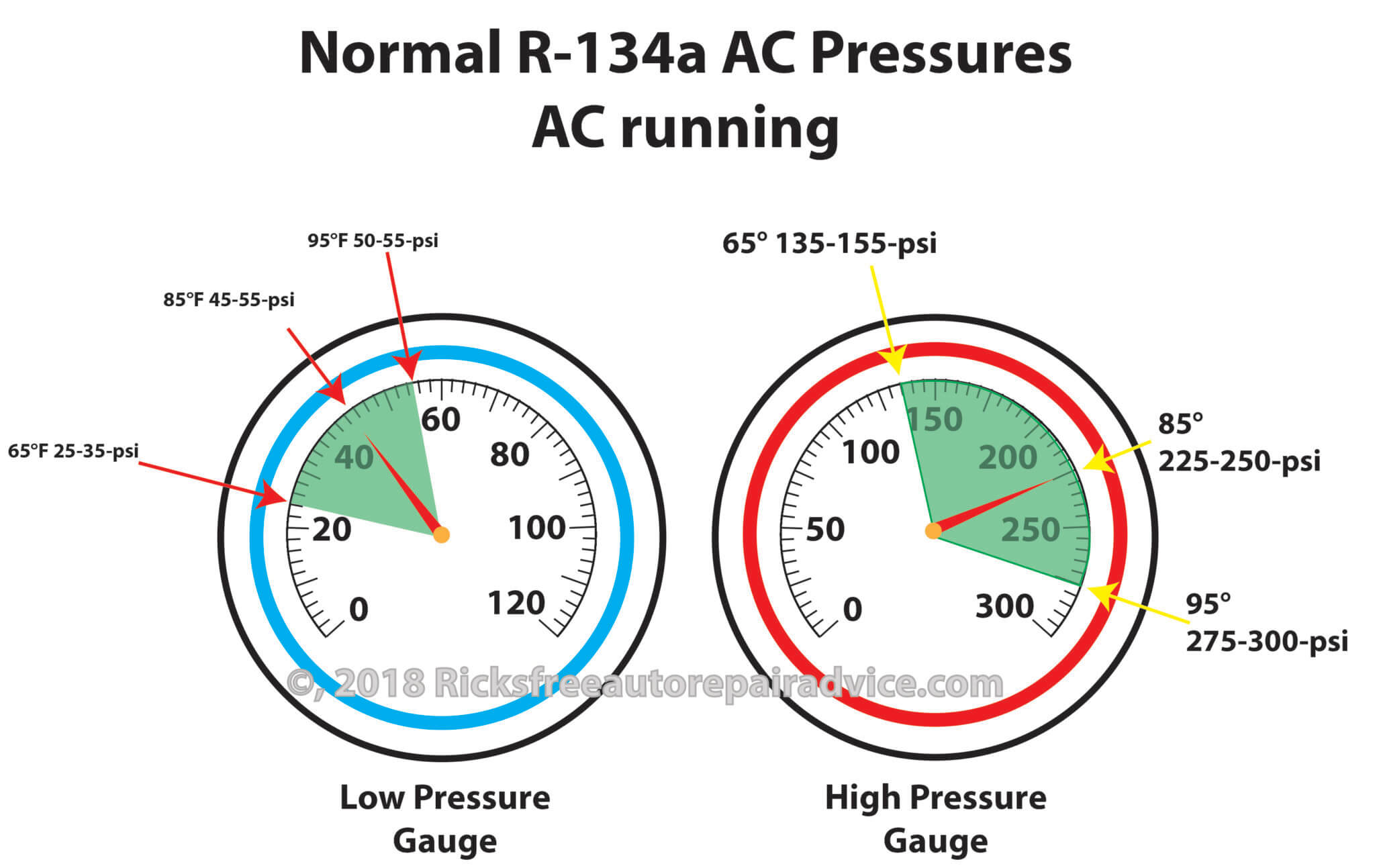

A/C pressure readings are typically measured using a manifold gauge set. This tool connects to the high-side and low-side service ports on the A/C system. Two gauges display the pressure in pounds per square inch (psi). The ambient temperature significantly impacts these readings, so always note the ambient temperature when taking measurements.

Normal Pressure Ranges (R-134a)

These ranges are approximate and can vary slightly depending on the vehicle and system design. Always consult the vehicle's service manual for specific recommendations.

- Low-Side Pressure: Typically, 25-45 psi. This pressure is measured after the refrigerant has passed through the evaporator. Lower than normal pressure suggests low refrigerant, while higher than normal can indicate a restriction in the system.

- High-Side Pressure: Typically, 150-250 psi or higher. This pressure is measured after the refrigerant has been compressed and passed through the condenser. High-side pressure readings are heavily influenced by ambient temperature.

Normal Pressure Ranges (R-1234yf)

R-1234yf systems operate at slightly different pressures than R-134a systems. The same principles of operation apply but expect to see higher pressures generally.

- Low-Side Pressure: 30-50 psi is common.

- High-Side Pressure: 170-270 psi or higher, dependent on ambient temperature.

Important Note: These pressure ranges are guidelines. Always consult the vehicle's service manual for the specific pressure specifications for your vehicle and refrigerant type. Using an incorrect refrigerant or misinterpreting pressure readings can damage the A/C system.

Interpreting Abnormal Pressure Readings

Deviations from the normal pressure ranges are strong indicators of underlying problems. Understanding these deviations is key to effective A/C diagnosis.

Low Low-Side and Low High-Side Pressure

Common Causes: Low refrigerant charge, compressor failure, or a leak in the system.

This is perhaps the most common scenario. A low refrigerant charge reduces the system's capacity to transfer heat effectively. Check for obvious leaks at connections, service ports, the condenser, and the evaporator. A UV dye test can help pinpoint leaks that are difficult to find. If the system is completely empty, it is imperative to find and repair the leak before recharging. A failed compressor might not be able to generate sufficient pressure.

High Low-Side and Low High-Side Pressure

Common Causes: Compressor issues (internal leakage), expansion valve/orifice tube problems.

This combination often indicates an internal problem with the compressor. For example, worn piston rings or valves inside the compressor can allow refrigerant to leak internally, reducing the high-side pressure and increasing the low-side pressure. A restricted or malfunctioning expansion valve or orifice tube can also cause this symptom.

Low Low-Side and High High-Side Pressure

Common Causes: Restriction in the high-side, overcharged system, condenser problems (blocked airflow).

A restriction, such as a clogged filter-drier or a kinked refrigerant line, can cause pressure to build up on the high side. An overcharged system can also lead to excessively high high-side pressures. Restricted airflow through the condenser (due to debris or a faulty cooling fan) will prevent adequate heat dissipation, also raising the high-side pressure. Carefully inspect the condenser fins for damage and ensure the cooling fan is operating correctly. Consider a refrigerant analysis; mixing refrigerants can cause odd pressure readings.

High Low-Side and High High-Side Pressure

Common Causes: Overcharged system, non-condensables in the system (air), a blockage in the condenser, or a faulty compressor.

An overcharged system has too much refrigerant, which can lead to excessive pressures on both sides. Non-condensable gases like air in the system can also elevate pressures. This is why proper evacuation of the system is crucial before recharging. Check for condenser restrictions, such as debris blocking airflow. A failing compressor can also cause this, as it struggles to effectively pump the refrigerant through the system.

Troubleshooting Tips and Considerations

- Use a Manifold Gauge Set Properly: Ensure the gauges are calibrated and that the hoses are properly connected to the service ports. Purge the hoses of air before taking readings to avoid introducing contaminants into the system.

- Consider Ambient Temperature: Pressure readings are significantly affected by ambient temperature. Consult a pressure-temperature chart for the specific refrigerant being used to determine expected pressure ranges at different temperatures. These charts are available online or in service manuals.

- Check for Leaks: Inspect all connections, service ports, the condenser, evaporator, and refrigerant lines for leaks. Use a UV dye leak detector to locate hard-to-find leaks.

- Inspect the Compressor: Listen for unusual noises from the compressor and check the compressor clutch for proper engagement.

- Evaluate the Condenser Fan: Ensure the condenser fan is operating correctly. A faulty fan can lead to high high-side pressures.

- Check the Expansion Valve/Orifice Tube: A restricted or malfunctioning expansion valve or orifice tube can cause a variety of pressure-related issues.

- Recover, Evacuate, and Recharge Properly: Use a refrigerant recovery machine to safely remove refrigerant from the system before performing any repairs. Evacuate the system to remove air and moisture, and then recharge with the correct amount of refrigerant according to the vehicle's specifications.

- Refrigerant Type: Never mix refrigerants. If converting from R-12 to R-134a (on older vehicles), ensure that the system is thoroughly flushed and that all necessary components, such as the expansion valve and receiver-drier, are replaced. Use extreme caution when working with R-1234yf systems, as this refrigerant is mildly flammable.

Real-World Example

A customer brings in a vehicle with complaints of weak A/C performance. Using a manifold gauge set at an ambient temperature of 85°F, the low-side pressure reads 20 psi, and the high-side pressure reads 120 psi. According to the pressure-temperature chart for R-134a, these readings are significantly low. A visual inspection reveals a small leak at the condenser. The condenser is replaced, the system is evacuated, and recharged to the specified amount. The A/C performance is restored, and the customer is satisfied.

Safety Precautions

Working with A/C systems involves handling pressurized refrigerants, which can be dangerous if not handled properly. Always wear safety glasses and gloves. Never release refrigerant into the atmosphere; use a refrigerant recovery machine. Be aware of the potential for frostbite from direct contact with liquid refrigerant. If working on R-1234yf systems, be mindful of the refrigerant's flammability. Disconnect the battery during repairs to prevent accidental activation of electrical components.

By understanding A/C pressure readings and their relationship to system performance, you can effectively diagnose and repair A/C problems, ensuring optimal cooling comfort for your vehicle.