Auto Air Conditioning Pressure Too High

The phenomenon of excessively high pressure within an automotive air conditioning (A/C) system is a critical concern for automotive professionals. Addressing this issue requires a comprehensive understanding of the system's components, refrigerants, operating principles, and potential failure modes. Ignoring this problem can lead to component damage, reduced efficiency, and even safety hazards.

Understanding Normal A/C System Operation and Pressure

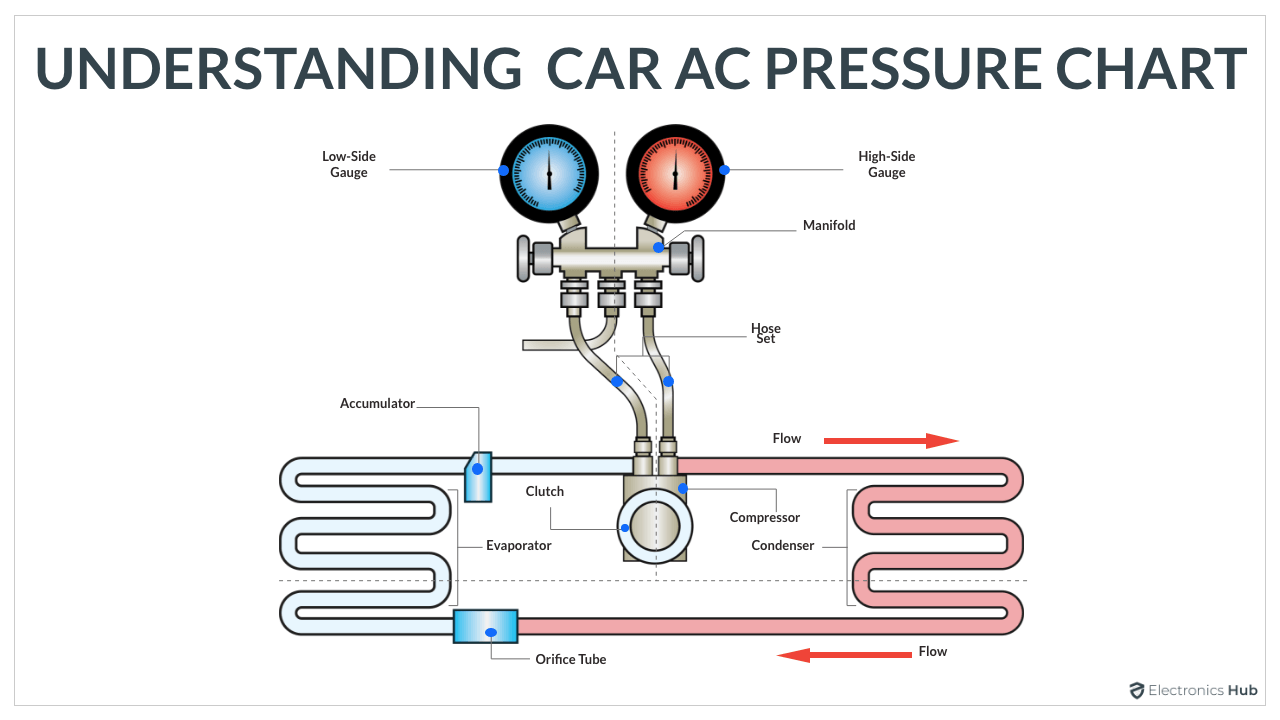

Before delving into high pressure scenarios, it's crucial to understand the normal A/C cycle. The core components are the compressor, condenser, expansion valve (or orifice tube), and evaporator. The refrigerant, currently predominantly R-134a but shifting towards R-1234yf, circulates through this closed loop, changing state between liquid and gas to absorb and release heat.

On the high side, between the compressor outlet and the expansion valve, the refrigerant exists as a hot, high-pressure gas. After passing through the condenser, it ideally transitions to a high-pressure, moderately warm liquid. Typical high-side pressures vary depending on ambient temperature and system load. As a general rule, expect pressures between 150 PSI and 250 PSI at normal operating temperatures with R-134a. R-1234yf pressures tend to be slightly lower at comparable conditions. Precise pressure readings must be verified against the vehicle manufacturer's specifications, which are often temperature-compensated charts.

Deviations from these normal ranges indicate a problem. High pressure, specifically, suggests an impediment to the refrigerant's ability to release heat and condense, or an overcharge of refrigerant.

Causes of High A/C Pressure

Several factors can contribute to excessively high A/C system pressure:

Overcharging the System

Adding too much refrigerant is a common mistake. A/C systems are designed to operate with a precise refrigerant charge. Overcharging reduces the volume available for expansion and condensation, leading to significantly elevated pressures. The effects are compounded at higher ambient temperatures.

Condenser Issues

The condenser's primary function is to dissipate heat from the hot, high-pressure refrigerant gas. Problems with the condenser include:

- Restricted Airflow: Debris (leaves, bugs, dirt) blocking the condenser fins significantly reduces its cooling capacity. This is a very common cause.

- Damaged Fins: Bent or crushed fins impede airflow and heat transfer.

- Internal Obstruction: Corrosion or debris within the condenser's tubes can restrict refrigerant flow and increase pressure. This is less common than external blockage.

- Failed Condenser Fan: If the vehicle has an auxiliary electric fan to assist the condenser at low speeds, a failed fan motor will dramatically raise high-side pressures, especially in stop-and-go traffic.

Non-Condensable Gases

Air and moisture are the most common non-condensable contaminants. These gases do not condense in the condenser like the refrigerant, occupying space and increasing the overall pressure within the system. Introducing non-condensables is typically the result of improper evacuation procedures during A/C service.

Refrigerant Contamination

Mixing different refrigerants (e.g., topping off an R-134a system with R-12) can create abnormally high pressures. Refrigerant recovery machines must be used to ensure proper refrigerant handling and prevent contamination. Furthermore, compressor oil contamination from additives or sealants can drastically affect performance.

Restriction in the High-Side Line

A kinked or collapsed high-side refrigerant line will impede flow and cause a pressure buildup upstream of the restriction. This is a less frequent occurrence but should be considered in cases where other causes are ruled out.

Compressor Malfunction

While a failing compressor can cause low-side issues, a partially blocked compressor discharge port could lead to higher than normal high-side pressure. However, this is less common than other factors.

Diagnosis and Troubleshooting

Accurate diagnosis is paramount. The following steps are crucial:

- Visual Inspection: Check the condenser for obstructions, damage, and proper fan operation. Inspect refrigerant lines for kinks or damage.

- Gauge Testing: Connect A/C manifold gauges to the high- and low-side service ports. Record the readings and compare them to the manufacturer's specifications, considering ambient temperature. A rapid rise in high-side pressure is a strong indicator of a problem.

- Temperature Measurement: Use an infrared thermometer to check the temperature of the condenser core in various locations. Uneven temperatures suggest partial blockage.

- Refrigerant Identification: Use a refrigerant identifier tool to confirm the type and purity of the refrigerant. This is critical, especially before connecting a refrigerant recovery machine.

- System Evacuation and Recharge: If contamination or overcharging is suspected, recover the refrigerant, evacuate the system to remove air and moisture, and recharge with the correct amount of specified refrigerant.

Alternatives and Engineering Choices

The automotive industry is actively transitioning to alternative refrigerants and system designs to improve efficiency and reduce environmental impact. R-1234yf is the most prominent alternative to R-134a. It has a significantly lower global warming potential (GWP) but is mildly flammable.

R-1234yf vs. R-134a:

- Pros of R-1234yf: Lower GWP, reduced environmental impact.

- Cons of R-1234yf: Mildly flammable, requires specialized service equipment, generally more expensive refrigerant.

Engineering choices regarding condenser design also affect pressure. Microchannel condensers are becoming increasingly common. They offer improved heat transfer compared to older tube-and-fin designs, allowing for more compact condensers and lower operating pressures (under optimal conditions).

Reliability and Maintenance

Proper A/C system maintenance is essential for reliability and longevity. Key maintenance practices include:

- Regular Inspections: Visually inspect the condenser for debris and damage. Check for refrigerant leaks.

- Filter/Drier Replacement: The filter/drier removes moisture and contaminants from the refrigerant. Replace it according to the vehicle manufacturer's recommendations. This is particularly crucial after opening the system for service.

- Proper Charging Procedures: Always use a calibrated A/C charging machine and adhere to the manufacturer's specified refrigerant charge.

- Leak Detection and Repair: Address refrigerant leaks promptly to prevent loss of refrigerant and potential compressor damage.

- System Flushing: If the system is contaminated with debris or oil, a complete system flush may be necessary.

Future Trends

The automotive industry is continuously evolving, and A/C systems are no exception. Future trends include:

- CO2 (R-744) Refrigerant: CO2 is a natural refrigerant with a very low GWP and excellent thermodynamic properties. However, it requires significantly higher operating pressures than R-134a or R-1234yf, presenting engineering challenges.

- Electric Compressors: Electrically driven compressors are becoming more prevalent, especially in hybrid and electric vehicles. These compressors offer improved efficiency and allow for independent A/C operation regardless of engine speed.

- Improved Condenser Designs: Continued advancements in condenser technology, such as microchannel designs and enhanced heat transfer coatings, will further improve A/C system efficiency.

- Sophisticated Control Systems: Advanced control systems will optimize A/C system performance based on real-time conditions, such as ambient temperature, humidity, and solar load.

Conclusion

High A/C pressure is a common but serious issue that automotive professionals must be equipped to address. By understanding the underlying causes, employing proper diagnostic techniques, and adhering to recommended maintenance practices, technicians can ensure the efficient and reliable operation of automotive A/C systems. The ongoing transition to new refrigerants and advanced system designs demands continuous learning and adaptation to meet the evolving needs of the automotive industry. As the industry moves towards electric vehicles and more stringent environmental regulations, the importance of efficient and sustainable A/C systems will only continue to grow. Automotive professionals who stay informed and adapt to these changes will be well-positioned to succeed in the future.