Automatic Transmission Stuck In 4th Gear

So, your automatic transmission is stuck in 4th gear. You've probably noticed a lack of initial acceleration, a sluggish feel, and maybe even a warning light on your dash. Don't panic! While it's a serious issue that needs addressing, understanding the possible causes can help you diagnose the problem and potentially save yourself a hefty repair bill. This article will walk you through the most common culprits, offering insights for experienced DIYers and modders.

Understanding "Limp Mode" or "Fail-Safe" Mode

Before diving into specific components, let's discuss the common symptom: your transmission being stuck in 4th gear. This is often referred to as "limp mode" or "fail-safe mode." Think of it as your car's way of protecting itself from further damage when it detects a significant problem. By limiting the transmission to a single gear (typically 3rd or 4th, depending on the manufacturer), the system aims to prevent further strain on potentially damaged components. This allows you to safely (albeit slowly) get the vehicle to a repair shop.

It's crucial to understand that limp mode isn't the *cause* of the problem; it's a *symptom* indicating an underlying issue. Simply resetting the system without addressing the root cause will likely result in the problem recurring.

Possible Causes: A Detailed Look

Let's explore the most common reasons your automatic transmission might be stuck in 4th gear:

1. Faulty Solenoids

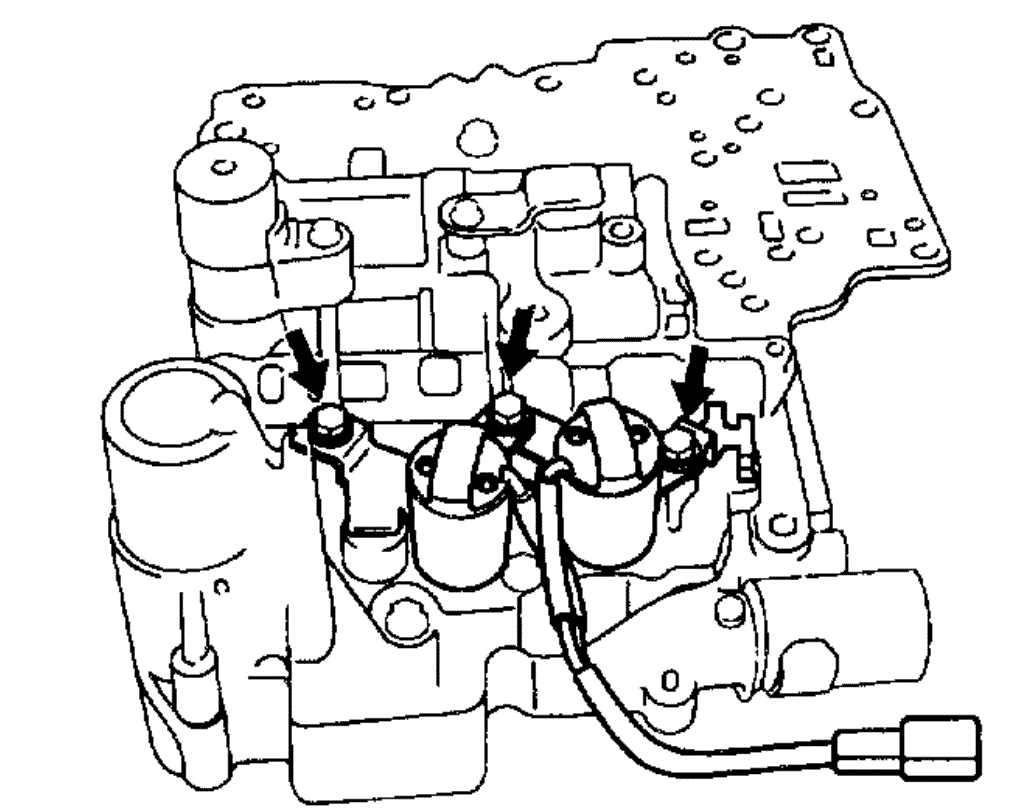

Solenoids are electromechanical valves that control the flow of transmission fluid to various parts of the transmission, enabling gear changes. They're essentially the "brains" behind the hydraulic operation. A failing or failed solenoid is a very common cause of transmission problems, including being stuck in a single gear.

How it works: Solenoids receive signals from the Transmission Control Module (TCM) – we'll get to that shortly – and open or close passages in the valve body. When a solenoid malfunctions, it might not open or close properly, preventing the transmission from shifting into the correct gear. A defective solenoid can also cause erratic shifting or harsh engagements.

Diagnosis: A diagnostic scan tool capable of reading transmission codes is essential here. Look for codes related to specific solenoids (e.g., "Shift Solenoid A Malfunction"). A multimeter can then be used to test the solenoid's resistance. An open circuit (infinite resistance) or a short circuit (zero resistance) indicates a faulty solenoid. Furthermore, you could physically inspect the solenoids after dropping the transmission pan. Look for debris or damage.

Repair: Replacing faulty solenoids often involves removing the transmission pan, accessing the valve body, and swapping out the defective unit. Be sure to use the correct type of transmission fluid after replacing solenoids.

2. Issues with the Transmission Control Module (TCM)

The Transmission Control Module (TCM), sometimes integrated with the Engine Control Module (ECM), is the computer that controls the automatic transmission. It receives input from various sensors (e.g., vehicle speed sensor, throttle position sensor) and uses this information to determine the appropriate gear and send signals to the solenoids.

How it works: A faulty TCM can misinterpret sensor data, send incorrect signals to the solenoids, or simply fail to operate properly, leading to shifting problems and limp mode. TCM failures can be caused by electrical damage, water intrusion, or internal component failure.

Diagnosis: Again, a diagnostic scan tool is crucial. Look for codes specifically related to the TCM itself. Additionally, check the TCM's wiring harness for damage, corrosion, or loose connections. Inspecting the TCM physically for signs of water damage or burnt components can also be helpful. Sometimes, issues within the ECM/PCM can also mimic TCM problems.

Repair: TCM repair can range from simple wiring repairs to complete TCM replacement. If replacement is necessary, the new TCM often needs to be programmed to match your vehicle's specific configuration. This usually requires specialized equipment and software.

3. Low or Contaminated Transmission Fluid

Transmission fluid is the lifeblood of your automatic transmission. It lubricates moving parts, cools the transmission, and provides hydraulic pressure to operate the clutches and bands. Low fluid levels or contaminated fluid can wreak havoc on transmission performance.

How it works: Low fluid levels reduce hydraulic pressure, making it difficult for the transmission to shift properly. Contaminated fluid, containing debris or friction material, can clog passages in the valve body and damage solenoids, leading to shifting problems. Over time, neglected fluid loses its lubricating properties and becomes less effective at cooling the transmission.

Diagnosis: Check the transmission fluid level using the dipstick (if your vehicle has one). The fluid should be at the correct level and appear clean and bright red or pink. Dark, burnt-smelling fluid is a sign of contamination. Look for metal shavings in the fluid, which indicate internal transmission damage.

Repair: A transmission fluid and filter change is the first step. If the fluid is severely contaminated, a transmission flush might be necessary. However, be cautious with flushes on older or high-mileage transmissions, as they can sometimes dislodge debris and cause further problems. If you find metal shavings, internal damage may be present, requiring further inspection and potentially a rebuild or replacement.

4. Faulty Sensors (Vehicle Speed Sensor, Throttle Position Sensor)

As mentioned earlier, the TCM relies on data from various sensors to determine the appropriate gear. The Vehicle Speed Sensor (VSS) and Throttle Position Sensor (TPS) are particularly important.

How it works: The VSS provides information about the vehicle's speed, while the TPS indicates the throttle position. If either of these sensors malfunctions, the TCM might receive incorrect data, leading to incorrect gear selection or limp mode.

Diagnosis: Diagnostic scan tools can often identify faulty VSS or TPS. You can also use a multimeter to test the sensors' output voltage or resistance. A reading outside the specified range indicates a faulty sensor.

Repair: Replacing a faulty VSS or TPS is usually a straightforward process. Ensure you purchase the correct sensor for your vehicle's make and model.

5. Internal Mechanical Problems

While less common than electrical or fluid-related issues, internal mechanical problems can also cause a transmission to get stuck in 4th gear. These problems can include worn or damaged clutches, bands, or gears.

How it works: Internal damage can prevent the transmission from properly engaging or disengaging gears, leading to shifting problems and limp mode. This damage is often the result of long-term wear and tear, overheating, or severe driving conditions.

Diagnosis: Diagnosing internal mechanical problems often requires a more in-depth inspection of the transmission. This might involve removing the transmission and disassembling it to inspect the internal components. Significant amounts of metal debris in the transmission fluid are a strong indicator of internal damage.

Repair: Repairing internal mechanical problems usually requires a transmission rebuild or replacement. A rebuild involves disassembling the transmission, replacing worn or damaged parts, and reassembling it. This is a complex and time-consuming process best left to experienced transmission technicians.

6. Wiring Harness Issues

A often-overlooked cause is damage to the wiring harness connecting the TCM to the various sensors and solenoids.

How it works: Broken, corroded, or shorted wires can interrupt the flow of signals, leading to incorrect data reaching the TCM and causing shifting problems. Vibrations, heat, and exposure to the elements can all contribute to wiring harness damage.

Diagnosis: Visually inspect the wiring harness for signs of damage, such as frayed wires, cracked insulation, or corroded connectors. Use a multimeter to check for continuity and shorts in the wiring circuits. A wiring diagram specific to your vehicle is essential for this process.

Repair: Repairing wiring harness issues can involve splicing damaged wires, replacing connectors, or, in severe cases, replacing the entire wiring harness. Ensure that all connections are properly secured and protected from the elements.

Important Considerations for DIYers

- Safety First: Always disconnect the negative battery terminal before working on any electrical components.

- Cleanliness: Keep your work area clean to prevent contamination of transmission components.

- Torque Specifications: Use a torque wrench to tighten bolts to the manufacturer's specified torque.

- Fluid Type: Use the correct type of transmission fluid for your vehicle.

- Documentation: Take pictures and notes as you disassemble components to aid in reassembly.

When to Seek Professional Help

While some of these repairs can be tackled by experienced DIYers, it's important to know when to seek professional help. If you're not comfortable working on complex automotive systems, or if you suspect internal transmission damage, it's best to consult with a qualified mechanic. A transmission rebuild or replacement is a significant undertaking that requires specialized knowledge and tools.

By understanding the potential causes of your automatic transmission being stuck in 4th gear, you can be better equipped to diagnose the problem and make informed decisions about repair options. Good luck!