Ball Height For Trailer Hitch

The ball height of a trailer hitch is a critical, often overlooked, parameter that significantly impacts towing safety, handling, and overall performance. For automotive professionals, understanding the intricacies of ball height selection and adjustment is paramount. This article delves into the technical aspects of ball height, compares it with alternatives, and discusses best practices for maintenance, reliability, and future trends.

Technical Specifications and Engineering Choices

Ball height, simply put, is the vertical distance from the ground to the top of the hitch ball when the tow vehicle is unladen and parked on a level surface. Standard trailer couplers are designed to mate with hitch balls at a specific height range. The Society of Automotive Engineers (SAE) has established standards, but a common rule of thumb is to aim for a ball height that results in a trailer that is either level or slightly nose-down when connected to the tow vehicle.

Understanding the Impact of Incorrect Ball Height

An incorrect ball height can have severe consequences. A trailer that is nose-up places excessive weight on the rear axle of the tow vehicle, potentially leading to reduced steering control, increased brake wear on the rear wheels, and a higher risk of trailer sway. Conversely, a trailer that is nose-down shifts weight to the front axle of the tow vehicle, which may cause the trailer to fishtail, reduce traction on the rear wheels, and increase strain on the trailer coupler.

Engineers consider several factors when designing hitch systems and advising on ball height. These include:

- Tow Vehicle Suspension: The type of suspension (leaf spring, coil spring, air suspension) and its condition directly affect ride height and therefore the required ball height. Worn or sagging suspensions will lower the vehicle and necessitate a higher hitch ball to maintain a level trailer.

- Trailer Design and Axle Placement: The trailer's axle placement and the overall design influence its natural ride height. Different trailer types (e.g., boat trailers, utility trailers, travel trailers) often require different ball heights.

- Load Distribution: How the load is distributed within the trailer also affects the ideal ball height. Improper loading can exacerbate the effects of an incorrect ball height.

- Hitch Receiver Class: Hitch receivers are classified by their weight carrying and towing capacity (Class I to V). The class dictates the receiver's design and inherent height, which in turn impacts the choice of ball mount.

Choosing the Right Ball Mount

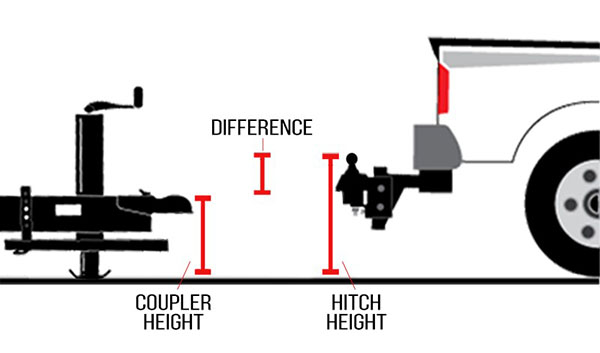

The ball mount (also known as a draw bar) is the crucial link between the hitch receiver and the hitch ball. Ball mounts come in various drop and rise configurations, allowing for precise adjustment of the ball height. Choosing the correct ball mount involves the following steps:

- Measure the receiver height: Measure the distance from the ground to the top of the hitch receiver opening.

- Measure the trailer coupler height: Measure the distance from the ground to the top of the trailer coupler when the trailer is level.

- Calculate the required drop or rise: Subtract the receiver height from the trailer coupler height. If the result is positive, you need a ball mount with a rise. If the result is negative, you need a ball mount with a drop.

- Consider the maximum drop/rise: Ensure that the chosen ball mount's drop or rise capability meets or exceeds the calculated requirement.

Alternatives to Traditional Ball Hitches

While ball hitches are the most common type of trailer hitch, alternatives exist for specialized applications:

- Gooseneck Hitches: Used primarily for heavy-duty towing, gooseneck hitches mount in the bed of the truck, directly over or slightly in front of the rear axle. They offer superior stability and weight capacity compared to ball hitches, but require significant modification to the tow vehicle.

- Fifth-Wheel Hitches: Similar to gooseneck hitches, fifth-wheel hitches are also used for heavy-duty towing, particularly for large travel trailers. They provide excellent stability and weight distribution but also necessitate in-bed mounting.

- Pintle Hitches: Employing a lunette eye and pintle hook, pintle hitches are rugged and suitable for off-road and industrial applications. They offer a looser connection than ball hitches, which can result in more noise and vibration.

Comparison of Ball Hitches with Alternatives

| Hitch Type | Pros | Cons | Typical Applications |

|---|---|---|---|

| Ball Hitch | Simple, inexpensive, widely available, compatible with a variety of trailers. | Lower weight capacity compared to alternatives, prone to sway with heavier loads. | Light to medium-duty towing of trailers, boats, and campers. |

| Gooseneck Hitch | High weight capacity, excellent stability, improved maneuverability. | Requires modification to the tow vehicle, less convenient for everyday use. | Heavy-duty towing of livestock trailers, flatbed trailers, and industrial equipment. |

| Fifth-Wheel Hitch | High weight capacity, excellent stability, comfortable towing experience. | Requires modification to the tow vehicle, takes up bed space when not in use. | Towing large travel trailers and RVs. |

| Pintle Hitch | Durable, suitable for rough terrain, allows for greater articulation. | Noisy, less precise connection, can result in more wear and tear on the towing system. | Industrial towing, construction equipment, military applications. |

Real-World Performance and Reliability

The impact of proper ball height is readily apparent in real-world towing scenarios. A correctly configured hitch significantly reduces trailer sway, improves braking performance, and enhances overall handling. Conversely, an incorrect ball height can lead to:

- Increased risk of accidents: Trailer sway and loss of control are major causes of towing accidents.

- Premature wear and tear: Uneven weight distribution can accelerate wear on tires, brakes, suspension components, and the hitch itself.

- Reduced fuel efficiency: Drag and instability can increase fuel consumption.

- Driver fatigue: Constant corrections to compensate for trailer sway and poor handling can lead to driver fatigue.

Reliability is paramount in towing applications. Regular inspection of the hitch system, including the ball mount, hitch ball, and trailer coupler, is essential. Look for signs of wear, corrosion, cracks, or deformation. The hitch ball should be properly sized for the trailer coupler and should be securely tightened to the ball mount with the correct torque. Always use a safety chain or cables that are properly rated for the trailer's weight.

Maintenance Tips

Proper maintenance extends the life of the hitch system and ensures safe towing. Here are some essential maintenance tips:

- Lubricate the hitch ball: Regularly grease the hitch ball to reduce friction and wear.

- Inspect the coupler mechanism: Ensure that the coupler latch mechanism is working smoothly and securely.

- Check the safety chains: Inspect the safety chains or cables for damage and ensure they are properly connected.

- Tighten all fasteners: Periodically check and tighten all bolts and nuts associated with the hitch system.

- Store the ball mount properly: When not in use, store the ball mount in a dry place to prevent corrosion.

Future Trends

The automotive industry is constantly evolving, and trailer hitch technology is no exception. Several trends are shaping the future of towing:

- Advanced Trailer Sway Control Systems: Modern vehicles are increasingly equipped with advanced trailer sway control systems that use sensors and electronic stability control to automatically mitigate trailer sway.

- Electric Trailer Brakes: Electric trailer brakes are becoming more common, providing improved braking performance and safety.

- Smart Towing Systems: Some manufacturers are developing "smart" towing systems that integrate with the vehicle's infotainment system to provide real-time information about trailer weight, tire pressure, and other parameters.

- Adjustable Ball Mounts: Ball mounts with adjustable height settings are becoming more sophisticated, allowing for easy customization to different trailers and load conditions.

- Autonomous Towing: The integration of autonomous driving technology into towing applications is a potential future development, which could significantly enhance safety and convenience.

Conclusion

Understanding and correctly implementing the proper ball height for trailer hitches is a fundamental aspect of safe and efficient towing. Automotive professionals must possess a thorough knowledge of the technical specifications, engineering considerations, and maintenance practices associated with hitch systems. As the automotive industry continues to innovate, staying abreast of emerging technologies and trends in towing will be crucial for ensuring the safety and satisfaction of customers. The move toward electric vehicles and more sophisticated driver-assistance systems will further integrate towing functionalities, requiring deeper expertise in this critical area. By prioritizing proper hitch selection, maintenance, and awareness of evolving technologies, automotive professionals can contribute to a safer and more enjoyable towing experience for all.