Battery Sparks When Connecting Negative

The seemingly innocuous spark that occurs when connecting the negative battery cable in a vehicle is a common observation, often dismissed with a shrug. However, for automotive professionals, understanding the underlying causes and potential consequences of this spark is crucial for safe and effective diagnostics, maintenance, and repair. This article delves into the technical aspects of this phenomenon, explores alternative charging system designs, and discusses the future trends impacting battery management in the automotive industry.

Understanding the Battery Spark Phenomenon

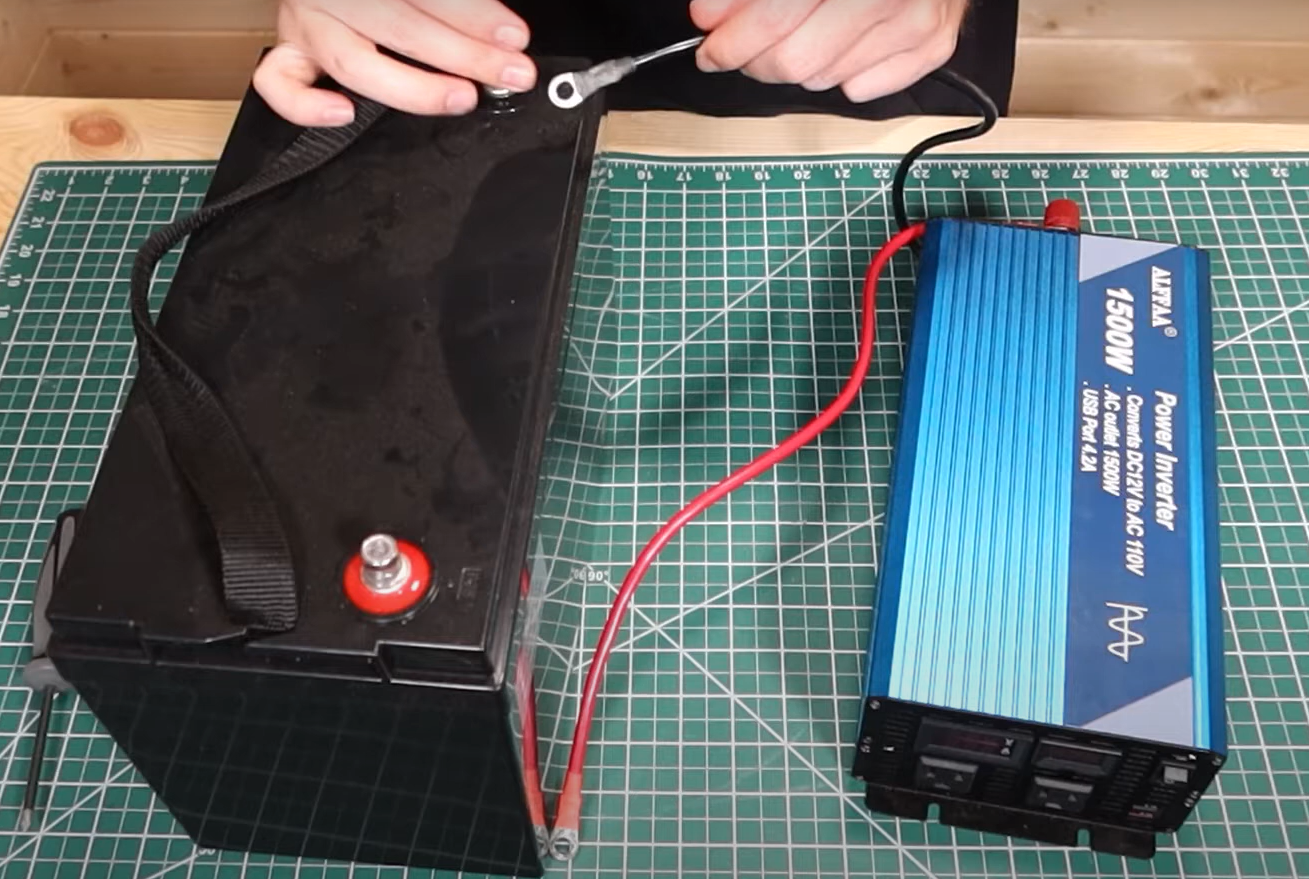

The spark observed during the final negative battery cable connection is essentially a miniature arc welding event. It's caused by a sudden surge of current as the vehicle's electrical system completes its circuit. Even with the ignition off, a modern vehicle has a significant parasitic draw, also known as dark current, which includes components like:

- Electronic Control Units (ECUs): Maintaining memory and monitoring sensors.

- Alarm Systems: Remaining active for security purposes.

- Remote Keyless Entry (RKE) Systems: Constantly listening for signals.

- Clock and Radio Presets: Requiring a small, continuous power supply.

This parasitic draw creates a voltage potential difference between the negative battery terminal and the vehicle's chassis ground. When the negative cable is connected, this potential difference is neutralized, resulting in a current flow. The magnitude of the spark is directly proportional to the current draw; a larger spark indicates a higher parasitic load.

Technical Specifications and Measurement

A healthy vehicle should exhibit a parasitic draw within a specified range, typically 25-85 milliamps (mA) for newer vehicles with complex electronic systems. Measuring this draw requires a digital multimeter (DMM) capable of measuring low amperage. The process involves disconnecting the negative battery cable, connecting the DMM in series between the cable and the negative battery terminal, and waiting for the vehicle's systems to "go to sleep" (typically 15-45 minutes). It's crucial to follow proper safety procedures, including:

- Wearing appropriate personal protective equipment (PPE), including eye protection and gloves.

- Ensuring the vehicle is in a well-ventilated area.

- Avoiding contact between the battery terminals and any metal objects.

- Consulting the vehicle's service manual for specific instructions and safety precautions.

A significantly higher-than-specified parasitic draw can indicate a faulty component or wiring harness causing excessive current leakage. Common culprits include malfunctioning ECUs, shorted interior lights, or aftermarket accessories that are not properly installed. Locating the source of the parasitic draw involves systematically disconnecting circuits and components to isolate the affected area.

Engineering Choices and Mitigation Strategies

Automotive engineers employ several strategies to minimize parasitic draw and reduce the intensity of the battery spark:

- Low-Power Microcontrollers: Utilizing microcontrollers with ultra-low power sleep modes to minimize current consumption when inactive.

- Optimized Software Algorithms: Designing software that efficiently manages power consumption and reduces unnecessary activity.

- Relay-Based Circuit Isolation: Employing relays to isolate circuits when not in use, preventing current leakage.

- Capacitive Filtering: Integrating capacitors to smooth out voltage fluctuations and reduce the surge current when the battery is connected.

However, completely eliminating parasitic draw is often impractical due to the need for certain systems to remain active. The design goal is to balance functionality with power efficiency.

Alternatives to Traditional Charging Systems

While the basic charging system architecture (alternator, battery, regulator) has remained relatively consistent, advancements in battery technology and energy management have led to the exploration of alternative designs.

Smart Alternators and Regenerative Braking

Smart alternators are electronically controlled and can adjust their output based on the vehicle's electrical load and the battery's state of charge. This improves fuel efficiency and reduces stress on the alternator. Many modern vehicles also incorporate regenerative braking systems, which capture kinetic energy during braking and use it to recharge the battery. This further reduces the load on the alternator and improves overall energy efficiency.

Advanced Battery Management Systems (BMS)

Sophisticated BMS are essential for managing advanced battery technologies like lithium-ion (Li-ion) batteries used in hybrid and electric vehicles (EVs). These systems monitor battery voltage, current, temperature, and state of charge to optimize performance and prevent damage. A BMS can also actively balance the charge between individual battery cells, extending the battery's lifespan. The integration of a comprehensive BMS significantly reduces the risk of uncontrolled current surges during connection, minimizing the battery spark.

Pros and Cons of Alternative Systems

Smart Alternators and Regenerative Braking:

- Pros: Improved fuel efficiency, reduced alternator wear, increased battery lifespan.

- Cons: More complex and expensive than traditional alternators, requires specialized diagnostic tools and training.

Advanced Battery Management Systems (BMS):

- Pros: Optimized battery performance, extended battery lifespan, improved safety, reduced risk of overcharging or discharging.

- Cons: Significantly more complex and expensive than traditional charging systems, requires specialized diagnostic and repair expertise.

Reliability, Maintenance, and Troubleshooting

While a small spark is generally considered normal, a large or persistent spark warrants investigation. This could indicate a significant parasitic draw, a short circuit, or a faulty component. Regular battery maintenance is crucial for preventing premature failure and ensuring optimal performance.

Maintenance Tips

- Regular Battery Testing: Use a battery load tester to assess the battery's health and capacity.

- Clean Battery Terminals: Remove corrosion from battery terminals using a battery terminal cleaner and a wire brush. Apply a corrosion inhibitor to prevent future corrosion.

- Check Charging System Voltage: Ensure the charging system voltage is within the specified range (typically 13.5-14.5 volts).

- Minimize Parasitic Draw: Disconnect unnecessary accessories or use a battery maintainer if the vehicle is stored for extended periods.

Troubleshooting

If a large spark is observed, follow these steps:

- Measure Parasitic Draw: Use a DMM to measure the parasitic draw and compare it to the vehicle's specifications.

- Isolate Circuits: Systematically disconnect circuits and components to identify the source of the parasitic draw.

- Inspect Wiring Harnesses: Check for damaged or corroded wiring harnesses, particularly in areas prone to moisture or heat.

- Diagnose ECUs: If a faulty ECU is suspected, use a diagnostic scan tool to check for error codes and perform functional tests.

Future Trends

The automotive industry is undergoing a rapid transformation, driven by electrification, autonomous driving, and connectivity. These trends are significantly impacting battery technology and energy management.

Higher Voltage Systems

Future EVs are likely to adopt higher voltage systems (e.g., 800V) to enable faster charging and reduce current flow, minimizing resistive losses. These high-voltage systems require advanced BMS and safety measures to prevent electrical hazards.

Solid-State Batteries

Solid-state batteries offer several advantages over traditional Li-ion batteries, including higher energy density, improved safety, and faster charging. These batteries are expected to play a significant role in the future of EVs.

Wireless Charging

Wireless charging technology is becoming increasingly popular for EVs, offering a convenient and contactless way to recharge the battery. This technology requires sophisticated power electronics and control systems to ensure efficient and safe charging.

Conclusion:

The battery spark, while often dismissed as a minor event, provides valuable insight into the health and efficiency of a vehicle's electrical system. Understanding the underlying causes, implementing proper maintenance procedures, and staying abreast of emerging technologies are essential for automotive professionals to effectively diagnose and repair modern vehicles. As the automotive industry continues to evolve, a deep understanding of battery management and energy efficiency will become increasingly critical for success.