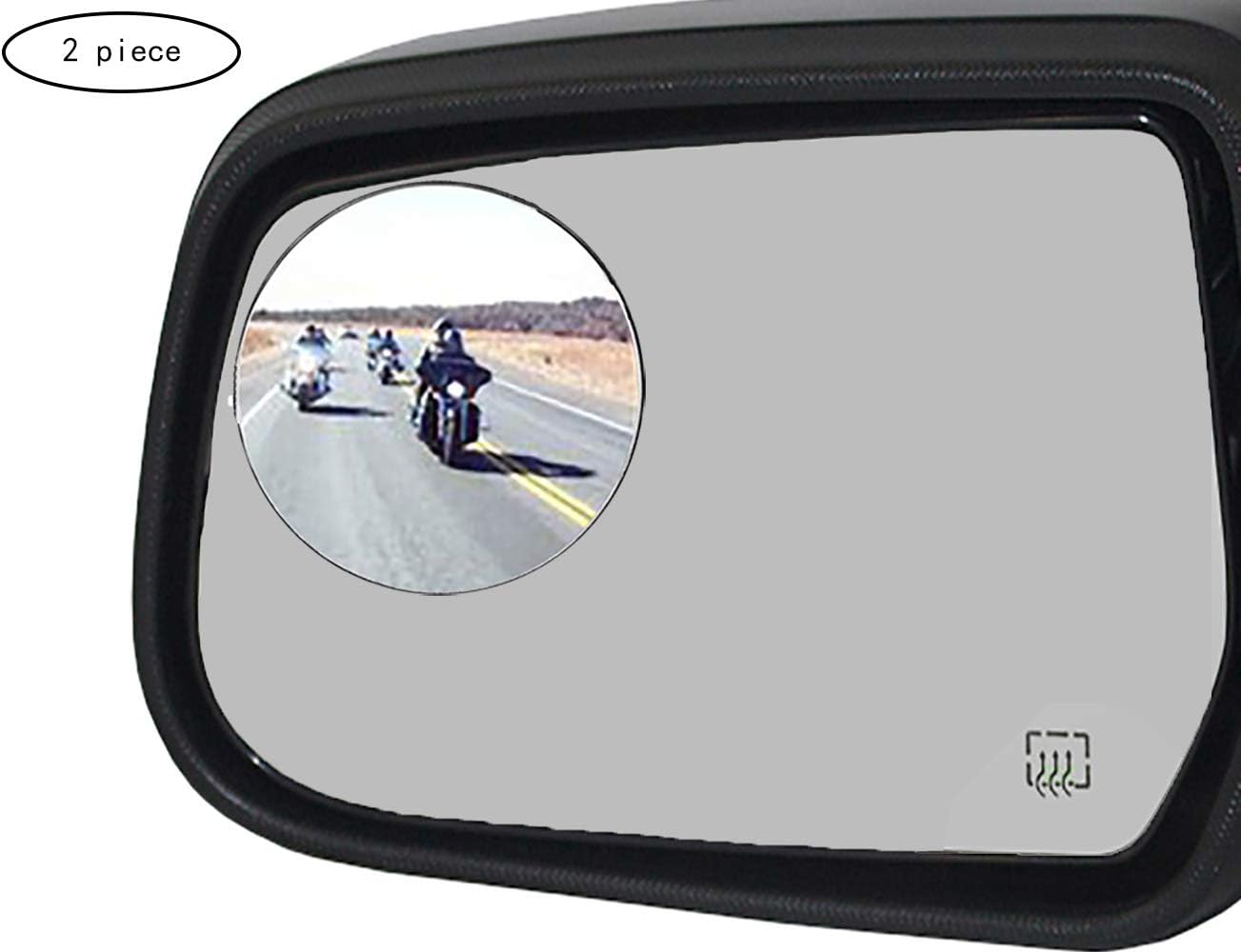

Blind Spot Mirrors For Trucks

For decades, the humble blind spot mirror has been a critical, if often overlooked, safety component for truck drivers. Glued onto side mirrors, these convex lenses offer a wider field of view, helping drivers spot vehicles lurking in those perilous areas where a direct line of sight is obscured. But in an era of rapidly evolving automotive technology, the question arises: are blind spot mirrors destined for obsolescence, or can they evolve to remain relevant in the future of trucking?

The answer, unsurprisingly, is a bit of both. While standalone blind spot mirrors might eventually fade into memory, the core function they provide – enhanced visibility – will be integrated and augmented by a wave of sophisticated technologies already hitting the road and poised to become ubiquitous in the coming years. The future isn't about eliminating the concept, it's about enhancing it.

The Rise of Digital Vision Systems

One of the most promising replacements for traditional blind spot mirrors is the digital vision system (DVS). These systems utilize cameras mounted on the truck’s exterior, feeding real-time video to screens inside the cabin. Advantages are immediately apparent:

- Elimination of Blind Spots: Cameras offer a significantly wider field of view than mirrors, potentially covering all blind spots entirely.

- Enhanced Night Vision: Many DVS systems incorporate infrared or low-light cameras, providing superior visibility in darkness or adverse weather conditions.

- Customizable Displays: Drivers can often adjust the displayed view, zoom in on specific areas, or even overlay information like lane markings and object detection warnings.

- Aerodynamic Improvements: By replacing large, protruding mirrors with smaller cameras, DVS can reduce drag and improve fuel efficiency – a crucial factor for long-haul trucking.

Several companies are already offering DVS solutions, and adoption is growing, particularly in Europe where regulations are increasingly favoring camera-based systems. However, challenges remain. Driver acceptance is a major hurdle; some drivers, accustomed to the familiar perspective of mirrors, find the transition to screens disorienting. Furthermore, the reliability of these systems in all weather conditions is paramount. Rain, snow, and glare can significantly degrade camera performance. Robust cleaning systems and advanced image processing algorithms are essential to ensuring consistent visibility.

Beyond basic visibility, DVS systems open the door to a host of advanced safety features. Imagine a system that not only shows you what's in your blind spot, but also automatically alerts you to potential collisions, or even gently steers the truck back into its lane if a merge is unsafe. This is the potential of integrating DVS with other advanced driver-assistance systems (ADAS).

Integrating with ADAS and Autonomous Driving

The convergence of DVS, ADAS, and eventually, autonomous driving technologies, is where the real revolution in truck safety lies. Blind spot monitoring becomes just one piece of a larger, integrated safety ecosystem. Consider these possibilities:

- Adaptive Cruise Control (ACC): ACC systems that utilize DVS to maintain a safe following distance even when vehicles are merging into the truck's blind spot.

- Lane Keeping Assist (LKA): LKA systems that use DVS to detect lane markings and prevent unintentional lane departures, taking into account vehicles in adjacent lanes.

- Automatic Emergency Braking (AEB): AEB systems that can automatically apply the brakes if a collision is imminent, even if the driver is distracted or unable to react quickly. The DVS provides an extra layer of perception to ensure the system is as accurate as possible.

As trucking moves closer to higher levels of autonomy, DVS will become even more critical. Self-driving trucks will rely heavily on camera-based vision systems to navigate safely and efficiently. Redundancy will be key; multiple cameras and sensors will work in concert to provide a comprehensive view of the surrounding environment, ensuring that the truck can operate safely even if one system fails.

Electric and Hybrid Trucks: A New Era of Safety Considerations

The shift towards electric and hybrid powertrains in trucking is also impacting the evolution of blind spot monitoring. Electric trucks, in particular, present some unique challenges and opportunities:

- Quieter Operation: Electric trucks are significantly quieter than their diesel counterparts, which can make them more difficult for pedestrians and cyclists to hear. This increases the importance of visual aids like blind spot mirrors and DVS to compensate for the lack of audible warning.

- Regenerative Braking: Electric trucks utilize regenerative braking, which can slow the vehicle down without activating the brake lights. This can be confusing for drivers behind the truck, particularly if they are in the truck's blind spot. Advanced DVS systems could potentially incorporate brake light indicators on the display to provide a visual warning to following drivers.

- Energy Efficiency: As mentioned earlier, DVS can improve aerodynamic efficiency, which is particularly important for electric trucks, where range is a major concern.

Furthermore, the electric truck revolution is fostering a new wave of innovation in sensor technology. Manufacturers are investing heavily in developing smaller, lighter, and more efficient cameras and sensors that can be seamlessly integrated into the vehicle's design. This is leading to more aesthetically pleasing and functional DVS systems.

Smart Automotive Solutions and the Connected Truck

The future of blind spot monitoring is inextricably linked to the concept of the connected truck. By connecting trucks to the internet and to each other, a wealth of new safety possibilities emerges:

- Real-time Hazard Alerts: Trucks could share information about road conditions, traffic congestion, and potential hazards with other vehicles in the area. This could include alerts about vehicles in blind spots, giving drivers an early warning of potential collisions.

- Predictive Maintenance: Data from DVS cameras could be used to monitor the condition of the truck's mirrors and cameras, alerting maintenance personnel to potential problems before they become critical.

- Remote Monitoring: Fleet managers could remotely monitor the performance of their drivers, including their use of blind spot mirrors and DVS systems. This could help identify areas where drivers need additional training.

However, the connected truck also presents some challenges. Cybersecurity is a major concern; connected vehicles are vulnerable to hacking, which could compromise their safety and security. Data privacy is another important issue; the vast amount of data collected by connected trucks must be protected from unauthorized access.

The Challenges Ahead

Despite the enormous potential of these technologies, significant challenges remain before they can be widely adopted:

- Cost: Advanced DVS systems and ADAS features are still relatively expensive, which can be a barrier to adoption, particularly for smaller trucking companies.

- Regulation: Regulations regarding the use of DVS and autonomous driving technologies vary widely from country to country and even from state to state. Clear and consistent regulations are needed to provide manufacturers with a clear path forward.

- Cybersecurity: As mentioned earlier, cybersecurity is a major concern that must be addressed before connected trucks can be widely deployed.

- Driver Training: Drivers need to be properly trained on how to use these new technologies. A poorly trained driver can actually be less safe with advanced technology than without it.

- Weather Reliability: Ensuring the reliability of camera systems in all weather conditions (rain, snow, fog, intense sun) is crucial.

Overcoming these challenges will require collaboration between manufacturers, regulators, and the trucking industry as a whole.

A Visionary Note

The future of blind spot monitoring is not just about replacing mirrors with cameras. It's about creating a safer, more efficient, and more connected transportation system. It's about using technology to empower drivers, prevent accidents, and ultimately, save lives. Imagine a world where truck accidents are a rarity, where roads are safer for everyone, and where goods are transported more efficiently than ever before. This is the future we can build, and the humble blind spot mirror, in its evolved digital form, will play a vital role in making it a reality. The future is bright, technologically advanced, and constantly evolving. Adaptation and embracing innovation are the keys to success in this rapidly changing landscape.