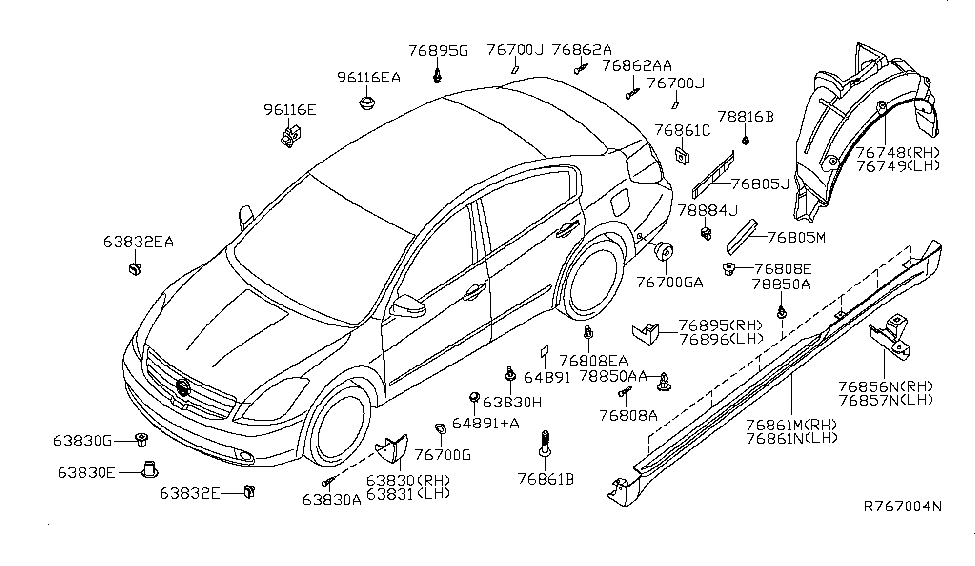

Body Parts For Nissan Altima

The Nissan Altima, a mainstay in the mid-size sedan market, owes its structural integrity and aesthetic appeal to a carefully engineered arrangement of body parts. Understanding the function and construction of these components can provide valuable insight into vehicle design, crashworthiness, and repair procedures. This guide delves into the anatomy of the Altima's body, exploring key areas and offering a technical perspective.

The Unibody Foundation: Strength and Rigidity

Unlike older vehicles with separate frames, the Altima utilizes a unibody construction, also known as a monocoque. This means the body and frame are integrated into a single structure. This design offers several advantages, including reduced weight, improved fuel efficiency, and enhanced handling. The unibody acts as a stressed skin, distributing loads across the entire structure rather than concentrating them in specific areas.

Key Unibody Components:

- Frame Rails: Running longitudinally along the vehicle's underside, frame rails are robust steel members that provide the primary structural support. They resist bending and twisting forces, protecting occupants in the event of a collision. Their design often incorporates crush zones, engineered areas designed to collapse in a controlled manner to absorb impact energy.

- Pillars (A, B, C): These vertical supports connect the roof to the unibody. The A-pillars frame the windshield, the B-pillars are located between the front and rear doors, and the C-pillars are behind the rear doors. They contribute significantly to rollover protection and overall structural rigidity. High-strength steel is often used in their construction.

- Rocker Panels: Situated below the doors, the rocker panels provide lateral stiffness and connect the front and rear sections of the unibody. They are particularly important in side-impact collisions.

- Floor Pan: The floor pan forms the foundation of the passenger compartment and provides a mounting surface for seats, consoles, and other interior components. Its design incorporates reinforcing ribs and crossmembers to enhance its strength.

- Firewall: Separating the engine compartment from the passenger compartment, the firewall is a critical safety component. It protects occupants from engine fires and fumes, and it also contributes to noise reduction.

Exterior Panels: Aerodynamics and Aesthetics

The exterior panels of the Altima serve both aerodynamic and aesthetic purposes. They are typically made of stamped steel, although aluminum and composite materials are increasingly used in some areas to reduce weight. Panel design has a significant impact on fuel efficiency, wind noise, and overall vehicle appearance.

Exterior Panel Breakdown:

- Hood: The hood provides access to the engine compartment and also plays a role in pedestrian safety. Modern hoods often incorporate crumple zones to absorb impact energy in a pedestrian collision.

- Fenders: Located above the wheels, fenders protect the body from debris and also contribute to the vehicle's aerodynamic profile. They are typically bolted to the unibody, allowing for relatively easy replacement in the event of minor damage.

- Doors: Doors provide access to the passenger compartment and are critical for occupant safety. They incorporate side-impact beams to protect occupants in side collisions. Door construction involves inner and outer panels, with reinforcement structures sandwiched in between.

- Roof: The roof provides structural support and protection from the elements. Sunroofs and moonroofs require careful integration into the roof structure to maintain its integrity.

- Trunk Lid/Hatchback: The trunk lid or hatchback provides access to the cargo area. Modern designs often incorporate aerodynamic features, such as spoilers or integrated lips, to reduce drag.

- Bumpers: Bumpers are designed to absorb low-speed impact energy and protect the vehicle's underlying structure. They consist of an outer cover, an energy-absorbing foam core, and a reinforcing beam. The design of the bumper is regulated by safety standards to minimize damage in minor collisions.

Crashworthiness and Safety Features

Modern vehicle design places a strong emphasis on crashworthiness. The Altima incorporates numerous safety features designed to protect occupants in the event of a collision. These features are integrated into the body structure and play a crucial role in mitigating injury.

Key Safety Features Embedded in the Body:

- Crush Zones: As mentioned earlier, crush zones are strategically located areas designed to collapse in a controlled manner during a collision. This absorbs impact energy and reduces the forces transmitted to the passenger compartment. They are typically found in the front and rear of the vehicle.

- High-Strength Steel: High-strength steel is used extensively throughout the Altima's body structure, particularly in critical areas such as the A-pillars, B-pillars, and frame rails. This material provides increased strength and resistance to deformation, enhancing occupant protection.

- Side-Impact Beams: Integrated into the doors, side-impact beams provide added protection in side collisions. They are typically made of high-strength steel and are designed to distribute impact forces across the door structure.

- Reinforced Passenger Compartment: The passenger compartment is designed to be a rigid "safety cage" that protects occupants from intrusion in a collision. This is achieved through the use of high-strength steel and careful structural design.

Materials and Manufacturing

The choice of materials and manufacturing processes plays a critical role in determining the performance and durability of the Altima's body. Steel remains the primary material, but aluminum and composites are increasingly used to reduce weight and improve fuel efficiency.

Material Considerations:

- Steel: Various grades of steel are used, including mild steel, high-strength steel (HSS), and ultra-high-strength steel (UHSS). HSS and UHSS are used in areas requiring maximum strength and impact resistance.

- Aluminum: Aluminum is lighter than steel and offers excellent corrosion resistance. It is increasingly used in body panels, such as the hood and trunk lid, to reduce weight.

- Composites: Composites, such as fiberglass and carbon fiber, offer exceptional strength-to-weight ratios. They are typically used in specialized applications, such as aerodynamic components and body panels on high-performance vehicles.

Manufacturing Processes:

- Stamping: Stamping is the primary manufacturing process for producing body panels. It involves pressing sheet metal between dies to form the desired shape.

- Welding: Welding is used to join various body components together. Different welding techniques are employed, including resistance welding, MIG welding, and laser welding.

- Adhesive Bonding: Adhesive bonding is increasingly used to join body panels, particularly in areas where welding is not feasible or desirable. It offers advantages such as reduced stress concentrations and improved corrosion resistance.

Repair and Maintenance Considerations

Understanding the construction of the Altima's body is essential for proper repair and maintenance. Damage to the unibody structure requires specialized repair techniques to ensure the vehicle's structural integrity is restored. Replacing body panels is a common repair procedure, and it is important to use genuine Nissan parts or high-quality aftermarket alternatives to ensure proper fit and finish.

Key Repair Considerations:

- Unibody Repair: Unibody damage requires specialized equipment and training to properly repair. This includes frame straightening machines and welding equipment.

- Panel Replacement: Replacing damaged body panels is a relatively straightforward procedure, but it requires careful alignment and welding to ensure a seamless repair.

- Corrosion Protection: Corrosion is a major concern for vehicle bodies. Proper corrosion protection measures, such as rustproofing and paint touch-ups, are essential to prolong the life of the body.

In conclusion, the body of the Nissan Altima is a complex and carefully engineered structure designed to provide strength, safety, and aesthetic appeal. Understanding the function and construction of its various components is essential for appreciating the engineering that goes into modern vehicle design and for ensuring proper repair and maintenance. By utilizing advanced materials, innovative manufacturing processes, and sophisticated safety features, the Altima's body contributes significantly to the vehicle's overall performance and occupant protection.