Bushings For Rack And Pinion

Bushings are often overlooked, yet critically important, components in automotive steering systems, particularly in rack and pinion setups. Their primary function is to isolate the rack and pinion assembly from the vehicle's chassis, absorbing vibrations and minimizing noise transfer while allowing for controlled movement. This article delves into the technical specifications, engineering considerations, real-world performance, alternatives, reliability, maintenance, and future trends related to rack and pinion bushings.

Technical Specifications and Engineering Choices

Rack and pinion bushings are typically made from elastomeric materials, with rubber and polyurethane being the most common choices. The durometer, a measure of material hardness, is a crucial specification. Softer bushings (lower durometer) offer better vibration damping and noise reduction but may compromise steering precision and responsiveness. Harder bushings (higher durometer) provide a more direct feel, enhancing steering feedback and reducing deflection under load, but they transmit more vibrations and road noise. The ideal durometer is a compromise based on the vehicle's intended use and performance characteristics.

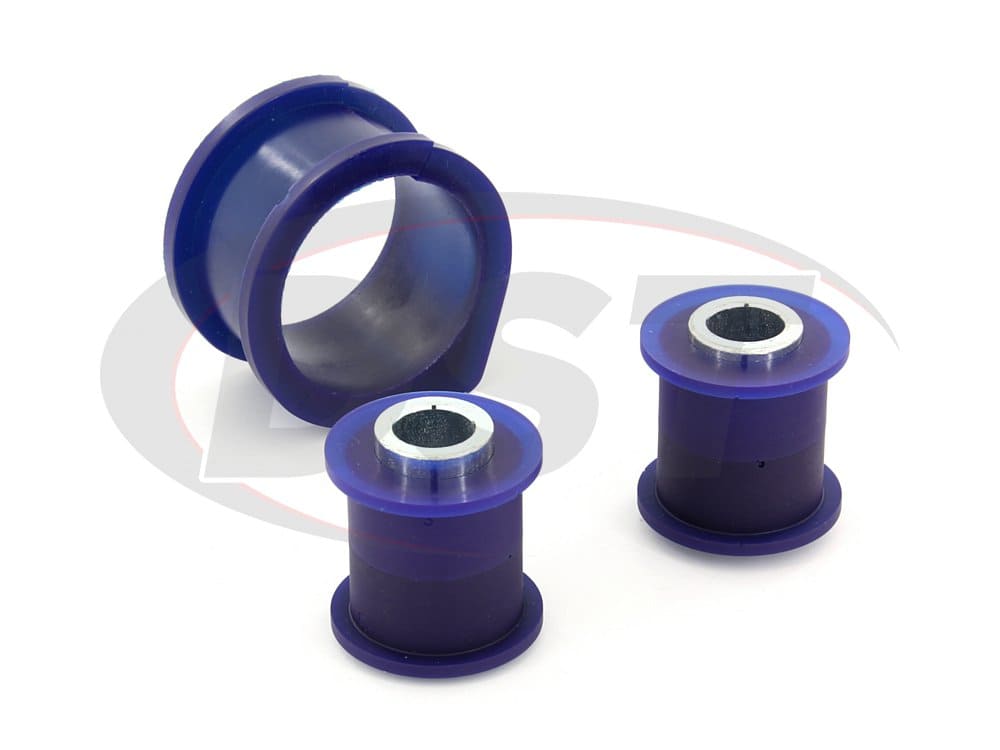

The bushing's design also plays a significant role. Common designs include:

- Sleeve bushings: Simple cylindrical bushings pressed into the rack housing. They offer basic support and vibration isolation.

- Flanged bushings: Similar to sleeve bushings but with a flange that provides additional surface area for load distribution and axial support.

- Spherical bushings: Employ a spherical bearing encased in rubber or polyurethane. These offer superior articulation and reduced binding, especially in applications with significant suspension travel.

- Hydraulic bushings: Contain fluid-filled chambers that provide variable damping based on the frequency of vibrations. These are often used in high-performance vehicles to balance comfort and handling.

The manufacturing process also affects bushing performance. Injection molding is a common method for producing rubber and polyurethane bushings, allowing for precise control over dimensions and material properties. Bonding the bushing material to a metal sleeve or housing is often necessary to ensure secure attachment and prevent slippage. The type of adhesive used and the bonding process itself can significantly impact the bushing's durability and resistance to environmental factors.

Real-World Performance and Alternatives

In the real world, rack and pinion bushings influence several key performance characteristics:

- Steering feel: Worn or inadequate bushings can result in vague or imprecise steering, making the vehicle feel less responsive.

- Vibration and noise: Degraded bushings transmit more road vibrations and noise into the cabin, reducing ride comfort.

- Wheel alignment: Excessive bushing play can affect wheel alignment, leading to uneven tire wear and handling instability.

- Steering response: Soft bushings can delay the vehicle's response to steering inputs, particularly during aggressive maneuvers.

The primary alternative to elastomeric bushings is roller bearings or needle bearings. While bearings offer minimal friction and extremely precise movement, they are considerably more expensive and require more sophisticated sealing to protect against contamination. Bearings are typically found in high-performance applications or race cars where minimizing friction and maximizing responsiveness are paramount. They are generally unsuitable for everyday vehicles due to their cost and maintenance requirements.

Pros and Cons of Rubber Bushings:

- Pros: Excellent vibration damping, low cost, readily available.

- Cons: Prone to degradation from ozone and UV exposure, less durable than polyurethane, softer durometer limits performance.

Pros and Cons of Polyurethane Bushings:

- Pros: High durability, resistant to oil and chemicals, available in a wide range of durometers, improved steering precision.

- Cons: Transmits more vibration and noise than rubber, can be more expensive than rubber, requires proper lubrication to prevent squeaking.

Pros and Cons of Bearing Solutions:

- Pros: Extremely low friction, maximum steering precision, minimal play.

- Cons: High cost, complex installation, requires meticulous maintenance, susceptible to contamination.

Reliability Aspects and Maintenance Tips

Rack and pinion bushings are subject to wear and tear from constant flexing, exposure to environmental elements, and contact with lubricating fluids. Common failure modes include:

- Cracking and tearing: Due to material fatigue or exposure to ozone and UV radiation.

- Swelling and softening: Due to contact with incompatible oils or chemicals.

- De-bonding: Separation of the bushing material from the metal sleeve or housing.

Regular inspection of rack and pinion bushings is crucial for maintaining optimal steering performance and preventing premature wear. Look for signs of cracking, tearing, or excessive play. Lubricating polyurethane bushings with a silicone-based grease can help reduce friction and prevent squeaking. Replacing worn bushings is a relatively straightforward repair that can significantly improve steering feel and handling. It's essential to use high-quality replacement bushings that meet or exceed OEM specifications.

To extend bushing life:

- Avoid exposing the steering system to harsh chemicals or solvents.

- Inspect the steering system regularly for leaks, which can damage bushings.

- Maintain proper wheel alignment to minimize stress on the bushings.

- Consider using polyurethane bushings for improved durability, especially in demanding applications.

Future Trends

Several trends are shaping the future of rack and pinion bushing technology:

- Advanced materials: Development of new elastomeric materials with improved durability, vibration damping, and resistance to environmental factors. This includes exploring advanced polymers and composites with tailored properties.

- Active damping systems: Integration of electronically controlled dampers within the bushings to provide variable damping based on driving conditions. These systems can optimize both comfort and handling.

- Smart bushings: Incorporation of sensors to monitor bushing condition and provide real-time feedback on wear and performance. This data can be used for predictive maintenance and optimizing steering system control.

- 3D printing: Using additive manufacturing techniques to create custom bushing designs with optimized geometry and material properties for specific applications.

Electric vehicles (EVs) also present new challenges and opportunities for bushing design. EVs generate less engine noise, making road and suspension noise more noticeable. This necessitates the use of bushings with enhanced vibration damping characteristics. Furthermore, the increased weight of EVs can put greater stress on suspension components, requiring more durable bushings.

Conclusion

Rack and pinion bushings are integral components of the steering system, significantly impacting vehicle handling, ride comfort, and overall performance. Understanding the technical specifications, engineering considerations, and maintenance requirements of these bushings is crucial for automotive professionals. As the automotive industry continues to evolve, with the rise of EVs and advanced driver-assistance systems (ADAS), expect to see further innovation in bushing technology to meet the demands of these new vehicles. The focus will be on developing bushings with enhanced durability, vibration damping, and intelligent features to optimize steering performance and improve the driving experience. The future will see a shift toward more sophisticated bushing designs that integrate seamlessly with advanced vehicle control systems, ensuring a safer and more enjoyable ride.