Cam Shaft Sensor Repair Cost

The camshaft position sensor (CMP), a seemingly small component nestled within your engine, plays a pivotal role in orchestrating the intricate dance of combustion. Acting as the engine's timing maestro, it relays critical information about the camshaft's position to the engine control unit (ECU), enabling precise fuel injection and ignition timing. When this sensor falters, the consequences can range from reduced fuel efficiency to a complete engine shutdown. Understanding the factors influencing camshaft position sensor repair cost is crucial for any vehicle owner. This guide delves into the sensor's function, symptoms of failure, diagnostic procedures, replacement steps, and associated costs.

Understanding the Camshaft Position Sensor

At its core, the CMP sensor is a transducer, converting mechanical information (the camshaft's rotational position) into an electrical signal. Most modern vehicles utilize either a Hall-effect sensor or a magnetoresistive sensor.

Hall-Effect Sensors

Hall-effect sensors operate on the principle that a voltage difference (the Hall voltage) is produced across an electrical conductor, transverse to an electric current in the conductor and a magnetic field perpendicular to both. A small magnet and a semiconductor element containing a current are placed near a toothed wheel (reluctor ring) attached to the camshaft. As the teeth of the wheel pass the sensor, they disrupt the magnetic field. This disruption alters the Hall voltage, creating a series of pulses. The ECU interprets these pulses to determine the camshaft's position.

Magnetoresistive Sensors

Magnetoresistive sensors, also known as variable reluctance sensors (VRS), rely on the change in resistance of a ferromagnetic material in the presence of a magnetic field. A coil of wire is wrapped around a permanent magnet. The reluctor ring passing near the sensor alters the magnetic flux, inducing a voltage in the coil. The frequency and amplitude of this voltage signal correlate directly to the camshaft's speed and position.

Regardless of the type, the sensor's output is a digital or analog signal that the ECU uses to synchronize fuel injection and ignition. This synchronization is especially critical in engines with variable valve timing (VVT) systems, where the camshaft position is actively adjusted to optimize performance and efficiency. Without accurate camshaft position data, the engine's performance suffers.

Symptoms of a Failing Camshaft Position Sensor

A malfunctioning CMP sensor can manifest in various ways, often mimicking other engine problems. Recognizing these symptoms is the first step towards accurate diagnosis and cost-effective repair.

- Check Engine Light: This is often the most immediate indication of a problem. The ECU detects an anomaly in the CMP sensor's signal and illuminates the malfunction indicator lamp (MIL). A diagnostic trouble code (DTC), such as P0340 (Camshaft Position Sensor Circuit Malfunction) or P0341 (Camshaft Position Sensor Range/Performance), will be stored in the ECU's memory.

- Rough Idling: The engine may idle erratically, stumble, or even stall. This occurs because the ECU is receiving inaccurate or intermittent information about the camshaft's position, leading to improper fuel injection and ignition timing at idle.

- Reduced Fuel Economy: Incorrect timing can lead to inefficient combustion, resulting in a noticeable decrease in fuel mileage. The engine may be consuming more fuel than usual to maintain performance.

- Hard Starting or No Start Condition: In some cases, a completely failed CMP sensor can prevent the engine from starting altogether. The ECU relies on the CMP signal to initiate the fuel injection and ignition sequence. Without it, the engine may crank but fail to fire.

- Engine Misfires: Erratic spark timing can cause misfires, resulting in a loss of power and rough running. The misfires may be intermittent or continuous, depending on the severity of the sensor's failure.

- Stalling: The engine might stall unexpectedly, especially at low speeds or when decelerating. This can be a dangerous situation, particularly in traffic.

- Loss of Power: The engine may feel sluggish and lack its usual power, especially during acceleration.

It's important to note that these symptoms can also be caused by other engine problems, such as a faulty crankshaft position sensor (CKP), vacuum leaks, or ignition system issues. Therefore, a thorough diagnosis is essential.

Diagnosing a Faulty Camshaft Position Sensor

Proper diagnosis is crucial to avoid unnecessary repairs. A systematic approach, using diagnostic tools and techniques, will help pinpoint the problem.

Retrieving Diagnostic Trouble Codes (DTCs)

The first step is to use an OBD-II scanner to retrieve any stored DTCs. This will provide a starting point for the diagnosis. Pay close attention to any codes related to the CMP sensor or the camshaft timing system. However, remember that a DTC only indicates a potential problem; it doesn't definitively diagnose the sensor's failure.

Visual Inspection

Inspect the CMP sensor and its wiring for any signs of damage, such as cracks, corrosion, or loose connections. Check the connector for proper seating and ensure that the wiring harness is not frayed or damaged. Sometimes, a simple visual inspection can reveal the culprit.

Testing the Sensor

A multimeter can be used to test the sensor's output voltage and resistance. Refer to the vehicle's service manual for the specific testing procedure and expected values.

For Hall-effect sensors, you can typically measure the voltage signal while the engine is cranking. The voltage should fluctuate as the camshaft rotates. A steady voltage or no voltage indicates a faulty sensor.

For magnetoresistive sensors, you can measure the resistance of the coil. An open circuit or a short circuit indicates a problem with the sensor.

Oscilloscope Analysis

An oscilloscope provides a graphical representation of the sensor's output signal, allowing for a more detailed analysis. You can observe the waveform's shape, amplitude, and frequency to identify any anomalies. This is particularly useful for detecting intermittent sensor failures.

Checking the Reluctor Ring

Inspect the reluctor ring on the camshaft for any damage, such as bent or broken teeth. Damage to the reluctor ring can disrupt the sensor's signal and cause false readings. In some cases, the reluctor ring is integrated into the camshaft, requiring camshaft replacement if damaged.

Camshaft Position Sensor Replacement Procedure

Replacing a CMP sensor is generally a straightforward task, but it's essential to follow the correct procedure to avoid damaging the engine or the new sensor. Always consult the vehicle's service manual for specific instructions and torque specifications.

- Disconnect the Negative Battery Terminal: This is a crucial safety step to prevent electrical shock and protect the vehicle's electrical system.

- Locate the Camshaft Position Sensor: The CMP sensor is typically located on the cylinder head, near the camshaft sprocket or at the rear of the engine. Refer to the service manual for the exact location.

- Disconnect the Electrical Connector: Carefully disconnect the electrical connector from the sensor. Be gentle to avoid damaging the connector or the wiring harness.

- Remove the Old Sensor: The sensor is usually held in place by a bolt or screw. Remove the bolt and carefully pull the sensor out of its mounting hole. Some sensors may be a tight fit due to O-rings or seals.

- Install the New Sensor: Lubricate the O-ring or seal on the new sensor with a small amount of clean engine oil. Align the sensor with the mounting hole and gently push it into place.

- Secure the Sensor: Install the retaining bolt or screw and tighten it to the manufacturer's specified torque. Overtightening can damage the sensor.

- Reconnect the Electrical Connector: Reconnect the electrical connector to the sensor, ensuring that it clicks into place securely.

- Reconnect the Negative Battery Terminal: Reconnect the negative battery terminal.

- Clear Diagnostic Trouble Codes: Use an OBD-II scanner to clear any DTCs that may have been stored during the repair process.

- Test the Engine: Start the engine and let it idle for a few minutes to ensure that the new sensor is functioning correctly. Check for any warning lights or unusual engine behavior.

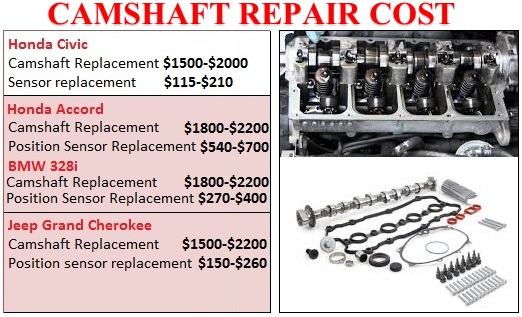

Camshaft Position Sensor Repair Cost Breakdown

The cost of replacing a camshaft position sensor can vary depending on several factors, including the vehicle's make and model, the sensor's location, and the labor rates in your area.

Parts Cost

The CMP sensor itself typically costs between $25 and $150. The price can vary depending on the sensor's quality, brand, and complexity. OEM (Original Equipment Manufacturer) sensors tend to be more expensive than aftermarket sensors, but they often offer better reliability and performance. Consider purchasing a quality aftermarket brand if budget is a major concern. Avoid the cheapest brands online as they often cause repeat failures.

Labor Cost

Labor costs can range from $50 to $200, depending on the complexity of the job and the mechanic's hourly rate. In some cases, the sensor is easily accessible and can be replaced in under an hour. However, in other cases, the sensor may be located in a difficult-to-reach area, requiring more time and effort to replace. Shops in major metropolitan areas usually have higher labor rates.

Total Cost

Therefore, the total cost to replace a camshaft position sensor can range from approximately $75 to $350. This is just an estimate, and the actual cost may vary depending on the specific circumstances.

Factors Affecting the Cost:

- Vehicle Make and Model: Some vehicles have more complex engine designs or sensor locations, which can increase the labor cost.

- Sensor Location: Sensors located in hard-to-reach areas will require more labor time to replace.

- Shop Labor Rates: Labor rates vary significantly from one shop to another.

- OEM vs. Aftermarket Parts: OEM sensors are typically more expensive than aftermarket sensors.

- Additional Repairs: In some cases, other related components, such as the wiring harness or connector, may need to be replaced, which can add to the overall cost. For example, rodent damage to the wiring harness is a common cause of sensor failure.

DIY vs. Professional Repair

Replacing a camshaft position sensor is a relatively straightforward repair that can be tackled by experienced DIYers. However, if you are not comfortable working on your vehicle's engine, it's best to leave the job to a qualified mechanic. Doing it yourself requires tools and the ability to properly torque the sensor. A mistake can cost you much more money than the labor savings.

Before attempting a DIY repair, make sure you have the necessary tools, including a socket set, a wrench set, a torque wrench, and an OBD-II scanner. Also, consult the vehicle's service manual for specific instructions and torque specifications.

Ultimately, understanding the camshaft position sensor, its function, the symptoms of failure, and the associated repair costs can empower you to make informed decisions about your vehicle's maintenance. By carefully diagnosing the problem and choosing a reputable repair shop or performing the repair yourself, you can ensure that your engine runs smoothly and efficiently for years to come.