Can You Reuse Flywheel Bolts

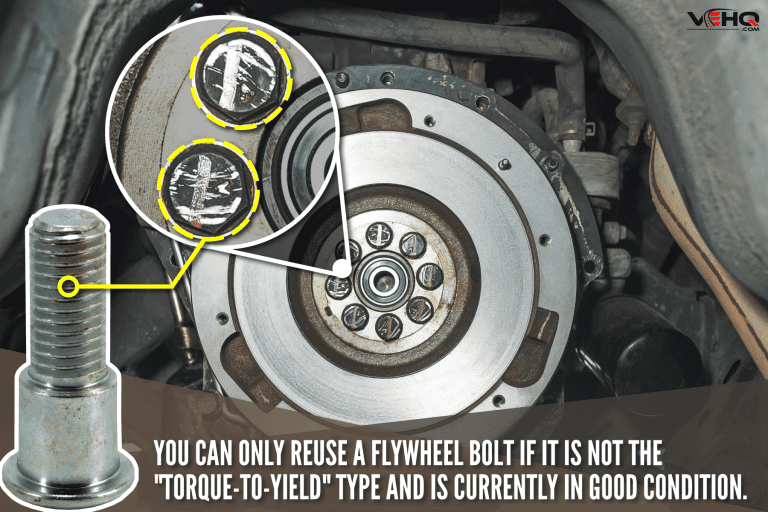

The humble flywheel bolt. It might seem like a small, insignificant part of your engine, but it's responsible for clamping the flywheel – the heavy disc that stores rotational energy – securely to the crankshaft. A failure here can lead to catastrophic engine damage, making the seemingly simple question of whether you can reuse flywheel bolts a surprisingly complex one. For the uninitiated, the short answer is: often no, but as is always the case with cars, the devil is in the details.

The Case Against Reusing Flywheel Bolts

Let's start with why you should probably ditch those old bolts. The primary reason is that many flywheel bolts are designed as torque-to-yield (TTY) or torque-angle fasteners. These bolts are intentionally stretched beyond their elastic limit when tightened. This stretching creates a very high clamping force and ensures a secure connection, even under the immense stresses of a revving engine. Once stretched, however, they don't return to their original shape, making them weaker and less reliable if reused.

Understanding Torque-to-Yield (TTY) vs. Torque-Angle

While often used interchangeably, there's a subtle difference between TTY and torque-angle bolts. TTY bolts are tightened to a specific torque value, beyond their yield point. Torque-angle bolts, on the other hand, are tightened to a lower initial torque and then further tightened by a specific angle (e.g., 90 degrees). This angle measurement provides a more precise way of achieving the desired stretch, regardless of slight variations in friction.

Here's a table summarizing the key differences:

| Feature | Torque-to-Yield (TTY) | Torque-Angle |

|---|---|---|

| Tightening Method | Torque Value | Torque Value + Angle |

| Precision | Less Precise | More Precise |

| Stretch Beyond Yield | Yes | Yes |

| Reusability | Generally Not Recommended | Generally Not Recommended |

If your car's service manual specifies a tightening procedure that includes an angle measurement, you're almost certainly dealing with a torque-angle bolt, and reusing them is a definite no-no.

Pros and Cons of Reusing Flywheel Bolts (Generally Not Recommended)

- Pros:

- Saves a small amount of money (bolts are relatively inexpensive).

- Potentially saves time if new bolts aren't immediately available.

- Cons:

- High risk of bolt failure: Reduced clamping force can lead to the flywheel loosening, causing vibrations, noise, and potential engine damage.

- Potential for catastrophic engine damage: A loose flywheel can shear the bolts, damage the crankshaft, and even crack the engine block.

- Increased risk of clutch slippage: Inconsistent clamping force can affect clutch engagement.

- Voids warranty: Using incorrect or worn parts may void any warranties on related components.

- False economy: The cost of replacing an engine far outweighs the cost of new bolts.

When *Might* You Consider Reusing? (And Why You Probably Still Shouldn't)

Okay, so we've established that reusing flywheel bolts is generally a bad idea. But are there any exceptions? Perhaps. Older vehicles, particularly those with low horsepower engines, may use standard, reusable bolts. These bolts are typically tightened to a specific torque value, and they don't stretch beyond their yield point. However, even in these cases, there are several factors to consider:

- Bolt Condition: Are the threads in good condition? Are there any signs of corrosion, stretching, or damage? If so, replace them.

- Original Equipment Manufacturer (OEM) Recommendation: Does the service manual explicitly state that the bolts can be reused? If not, err on the side of caution.

- Previous Use: How many times have the bolts been used before? If they've been torqued down multiple times, they may be fatigued.

- Your Risk Tolerance: Are you comfortable with the potential consequences of a bolt failure? If not, replace them.

Important Note: Even if you *think* your bolts are reusable, it's always a good idea to consult the service manual and inspect the bolts carefully. If you have any doubts, replace them. It's simply not worth the risk.

Real-World Driving Impressions (Or Lack Thereof!)

You won't *feel* a difference between new and old flywheel bolts – until something goes wrong. That's the insidious thing about this particular component. Everything might seem fine initially. You might even get away with reusing bolts for a while. But eventually, the weakened bolts will fail, and the consequences can be dramatic. Imagine this: You're merging onto the highway, flooring the throttle, and suddenly you hear a loud bang and feel a violent vibration. The engine stalls, and you're stranded on the side of the road with a severely damaged engine. All because you tried to save a few bucks on flywheel bolts. This is a simplified, and dramatic, picture. More likely you would hear an increasing vibration or rattle over time.

Model and Engine Specific Considerations

The type of flywheel bolts used can vary significantly depending on the vehicle model and engine. Here are a few examples:

- Older American V8s (e.g., Small Block Chevy): Often used standard, reusable bolts. However, even these engines can benefit from upgraded ARP bolts for increased strength and reliability, especially in high-performance applications.

- Modern European Cars (e.g., BMW, Audi, VW): Almost always use torque-angle bolts. Replacing them is mandatory.

- Japanese Performance Cars (e.g., Subaru WRX, Mitsubishi EVO): Typically use torque-angle bolts. Replacement is highly recommended. Many aftermarket suppliers offer stronger alternatives.

Here's a small table highlighting some differences:

| Vehicle Example | Flywheel Bolt Type | Reusability | Notes |

|---|---|---|---|

| 1969 Chevrolet Camaro with 350 V8 | Standard Bolts | Potentially Reusable (Inspect Carefully) | Consider upgrading to ARP bolts for performance applications. |

| 2015 BMW 328i (F30) | Torque-Angle Bolts | Not Reusable | New bolts are essential. |

| 2004 Subaru Impreza WRX | Torque-Angle Bolts | Not Reusable (Highly Recommended to Replace) | Aftermarket ARP bolts are a popular upgrade. |

Conclusion: When in Doubt, Throw Them Out!

The bottom line is this: replacing flywheel bolts is cheap insurance against potentially catastrophic engine damage. Unless you have absolute certainty that your bolts are reusable and in perfect condition, spend the few extra dollars and replace them. It's one of those rare instances in the automotive world where the best solution is also the cheapest.

So, here's the fun debate starter: Let's say you're in a post-apocalyptic world. New flywheel bolts are impossible to find. You have a meticulously restored classic car that's your only means of survival. Do you risk reusing the old flywheel bolts, knowing the potential consequences, or do you try to fashion some makeshift replacements from scavenged metal?