Car Aircon Wiring Diagram Pdf

Understanding your car's air conditioning system is crucial for both comfort and safety, especially in hotter climates. A key resource for both car owners and mechanics in diagnosing and repairing AC issues is the wiring diagram. While you might not be rewiring your entire system, knowing how to interpret a wiring diagram can significantly aid in troubleshooting electrical problems within the AC system. This article provides a practical guide to using car aircon wiring diagrams, focusing on maintenance, troubleshooting, and real-world issues.

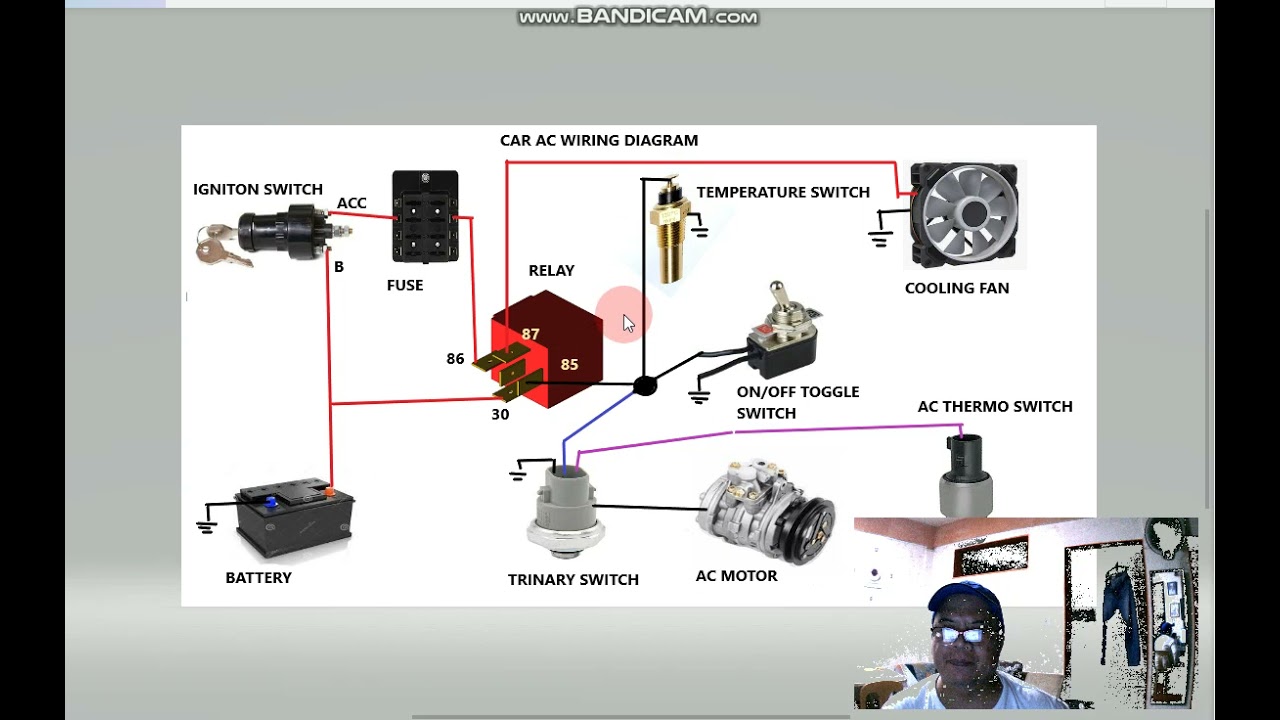

Understanding the Car Aircon Wiring Diagram

A car aircon wiring diagram is a schematic representation of the electrical circuits within the AC system. It shows the components, wires, connectors, and their interconnections. It's essentially a roadmap that helps you trace electrical signals and identify potential faults. Before diving into troubleshooting, let's discuss common components found in an AC wiring diagram:

- Compressor Clutch Relay: Controls the power to the compressor clutch.

- Pressure Switches: High and low-pressure switches protect the compressor from damage.

- Blower Motor: Powers the fan that circulates air.

- Blower Motor Resistor: Controls the fan speed.

- Temperature Sensor: Monitors the evaporator temperature.

- AC Control Unit: The brains of the operation, managing the AC system based on user input and sensor readings.

- Wiring and Connectors: The pathways for electrical signals.

When looking at a wiring diagram, pay attention to the symbols used for each component. These symbols are standardized, but it's always a good idea to consult the diagram's legend. Different colored wires represent different circuits and functions; the diagram will usually have a color code legend.

Common AC Problems and Troubleshooting with Wiring Diagrams

Let's explore some common AC problems and how a wiring diagram can help diagnose them:

1. AC Not Blowing Cold Air

Symptom: The AC system blows air, but it's not cold.

Possible Causes:

- Refrigerant leak

- Faulty compressor clutch

- Failed pressure switch

- Electrical issue in the AC control circuit

Troubleshooting with the Wiring Diagram:

Begin by checking the compressor clutch. Refer to the wiring diagram to locate the compressor clutch relay and the wiring leading to the clutch itself.

Problem: No voltage at the compressor clutch connector when the AC is turned on.

Solution:

- Use a multimeter to check the voltage at the compressor clutch relay. If there's no voltage coming into the relay, trace the wiring upstream towards the AC control unit using the wiring diagram. The problem might be a blown fuse, a faulty switch, or a break in the wiring.

- If there's voltage coming into the relay, but no voltage leaving the relay when the AC is on, the relay itself is likely faulty and needs replacement.

- Check the pressure switches. The wiring diagram will show where these switches are located in the circuit. A faulty high or low-pressure switch will prevent the compressor clutch from engaging. Bypass the switch temporarily (with caution!) to see if the compressor engages. Note: Bypassing pressure switches is for diagnostic purposes only and should not be a permanent solution.

Example (Honda Civic): The wiring diagram for a Honda Civic might show that the compressor clutch relay is located in the under-hood fuse box. It also shows the high and low-pressure switches connected in series with the compressor clutch circuit. If the low-pressure switch is faulty due to low refrigerant, the circuit will be broken, and the clutch won't engage.

2. AC Blower Not Working

Symptom: The AC blower fan doesn't blow air at all, or only works on some settings.

Possible Causes:

- Blown fuse

- Faulty blower motor resistor

- Bad blower motor

- Wiring issue

Troubleshooting with the Wiring Diagram:

Start by checking the fuse. The wiring diagram will indicate the fuse location for the blower motor circuit.

Problem: Blower motor only works on the highest setting.

Solution:

- The most likely cause is a faulty blower motor resistor. The resistor is responsible for controlling the fan speed on lower settings. Locate the blower motor resistor using the wiring diagram.

- Check the resistor for continuity using a multimeter. If there's no continuity through one or more of the resistor circuits, it needs to be replaced.

Problem: Blower motor doesn't work at all, even after replacing the fuse.

Solution:

- Check the voltage at the blower motor connector using the wiring diagram as a guide. If there's no voltage, trace the wiring back to the fuse box and the blower motor switch. There might be a break in the wire or a faulty switch.

- If there is voltage at the blower motor connector, the blower motor itself is likely faulty and needs replacement.

Example (Ford F-150): An F-150's wiring diagram will show that the blower motor resistor is often located near the blower motor itself, often behind the glove box. The diagram will also illustrate how the blower motor switch controls the ground path for the blower motor through the resistor, changing the fan speed.

3. AC Cycling On and Off Rapidly

Symptom: The AC compressor engages and disengages frequently, causing intermittent cooling.

Possible Causes:

- Low refrigerant

- Faulty pressure switch

- Problem with the expansion valve

Troubleshooting with the Wiring Diagram:

The rapid cycling is often due to the low-pressure switch cutting off the compressor when the refrigerant pressure drops too low.

Problem: AC compressor cycles on and off every few seconds.

Solution:

- Check the refrigerant level. If it's low, there's likely a leak in the system. A wiring diagram won't help you find the leak, but it will help you verify that the low-pressure switch is functioning correctly.

- Using the wiring diagram, identify the low-pressure switch. Monitor the voltage at the switch while the AC is running. If the voltage fluctuates rapidly along with the compressor cycling, the switch is likely reacting to low pressure.

Example (Toyota Camry): A Camry's wiring diagram will show the low-pressure switch connected to the AC amplifier (the control unit). The amplifier uses the signal from the low-pressure switch to protect the compressor. A leak in the system will cause the low-pressure switch to open and close repeatedly, leading to compressor cycling.

Safety Precautions

Working with electrical systems in a car can be dangerous. Always disconnect the negative battery terminal before working on any electrical components. Use a multimeter to check for voltage and continuity. Never bypass safety devices like pressure switches for extended periods. Wear appropriate safety gear, including eye protection.

Maintaining Your Car's AC System

Preventive maintenance is key to keeping your car's AC system in top condition. Here are some tips:

- Regular AC Service: Have the AC system checked and recharged as needed. This typically includes checking the refrigerant level, inspecting for leaks, and cleaning the condenser fins.

- Run the AC Regularly: Even in winter, running the AC for a few minutes each week helps keep the compressor lubricated and prevents seals from drying out.

- Inspect the Belts and Hoses: Check the compressor drive belt for cracks or wear. Replace any damaged belts or hoses.

- Keep the Condenser Clean: The condenser is located in front of the radiator and can become clogged with debris. Clean it periodically to ensure proper airflow.

Conclusion

Understanding how to use a car aircon wiring diagram is a valuable skill for both car owners and mechanics. It allows for more efficient troubleshooting and repair of AC system problems. By combining the knowledge of wiring diagrams with a systematic approach to diagnosis, you can keep your car's AC system running smoothly and comfortably for years to come. Remember to always prioritize safety and consult the vehicle's service manual for specific instructions and component locations. A well-maintained AC system not only provides comfort but also contributes to the overall reliability and value of your vehicle. Always consult a qualified mechanic if you are unsure about any aspect of AC system repair. Good luck!