Class 4 Trailer Hitch Rating

The Class 4 trailer hitch represents a significant step up in towing capability compared to lighter-duty options. It's a common choice for owners of mid-size trucks, SUVs, and vans who need to tow substantial loads, bridging the gap between recreational towing and light commercial applications. Understanding the technical specifications, engineering considerations, and real-world performance of Class 4 hitches is crucial for automotive professionals involved in sales, installation, repair, and maintenance.

Technical Specifications and Engineering

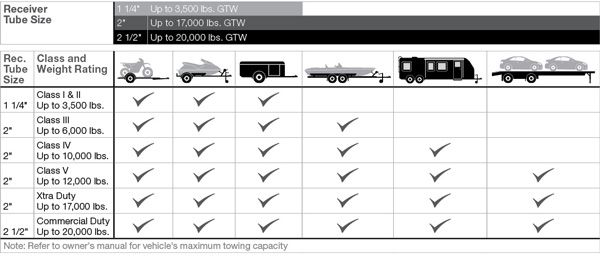

A Class 4 hitch, as defined by the Society of Automotive Engineers (SAE) J684 standard, is rated for a Gross Trailer Weight (GTW) range of 10,001 to 14,000 pounds and a Tongue Weight (TW) range of 1,001 to 1,400 pounds. These figures represent the maximum weight the hitch is designed to handle, including the trailer itself and any cargo it carries. It is imperative to always consult the vehicle manufacturer's towing capacity and never exceed the lowest rated component, whether it's the hitch, the vehicle's frame, axles, or tires.

Engineering a Class 4 hitch involves several critical considerations. The hitch typically utilizes a 2-inch receiver, allowing compatibility with a wide range of ball mounts and accessories. The hitch is constructed from high-strength steel, often employing welded construction for robustness. Key engineering aspects include:

- Material Selection: High-grade steel alloys are selected for their tensile strength and yield strength. Common choices include ASTM A36 or higher-grade steels.

- Welding Processes: Robotic welding is frequently used to ensure consistent weld quality and penetration. Welding procedures must adhere to stringent standards to prevent fatigue failures.

- Finite Element Analysis (FEA): FEA is used extensively in the design process to simulate stress distribution under various loading conditions. This helps optimize the hitch design for maximum strength and durability while minimizing weight.

- Fatigue Testing: Prototypes undergo rigorous fatigue testing to simulate the stresses experienced during real-world towing. This ensures the hitch can withstand the cyclic loading associated with long-term use.

- Corrosion Resistance: Hitches are typically coated with a durable finish, such as powder coating or e-coating, to protect against rust and corrosion. This is especially important in regions with harsh weather conditions.

Hitch Design Variations

While the Class 4 rating defines the weight capacity, various design implementations exist. Some common variations include:

- Frame-Mounted Hitches: These hitches are directly bolted to the vehicle's frame, providing a strong and secure connection.

- Cross-Tube Hitches: These hitches feature a cross-tube that spans the width of the vehicle's frame, distributing the towing load more evenly.

- Hidden Hitches: Designed for a cleaner appearance, these hitches are concealed behind the bumper when not in use. However, they may require modifications to the vehicle's bumper or fascia.

Comparison with Alternatives

Understanding the differences between Class 4 hitches and other classes is crucial for selecting the appropriate option.

- Class 3 Hitches: Rated for GTW up to 8,000 pounds and TW up to 800 pounds. Suitable for lighter towing applications like small boats or utility trailers. The primary difference lies in their lower weight capacity and often lighter-duty construction.

- Class 5 Hitches: Rated for GTW exceeding 14,000 pounds and TW exceeding 1,400 pounds. Used for heavy-duty towing applications such as large RVs or construction equipment. Class 5 hitches are significantly more robust and require heavy-duty vehicles with appropriate towing packages.

Pros and Cons of Class 4 Hitches

Pros:

- High Towing Capacity: Suitable for a wide range of trailers, including campers, boats, and equipment trailers.

- Versatility: Compatible with a 2-inch receiver, offering a broad selection of accessories.

- Strong and Durable: Constructed from high-strength steel for reliable performance.

- Wide Availability: Readily available for a variety of vehicle makes and models.

Cons:

- Can be Overkill: If only towing lighter loads, a Class 3 hitch may be more appropriate and cost-effective.

- Potential for Overloading: It's crucial to adhere to the vehicle's maximum towing capacity to prevent damage and safety risks.

- Installation Complexity: Installation can be complex, especially for hidden hitches, and may require professional assistance.

Real-World Performance

The real-world performance of a Class 4 hitch depends on several factors, including the quality of the hitch, the vehicle's towing capacity, and the driving conditions. Factors that are commonly assessed are:

- Towing Stability: A well-designed and properly installed Class 4 hitch provides excellent towing stability, minimizing sway and improving handling.

- Load Distribution: Proper load distribution is essential for safe towing. Uneven weight distribution can lead to instability and reduced braking performance.

- Braking Performance: When towing heavy loads, it's crucial to have adequate braking performance. Trailer brakes are often required for heavier trailers.

- Driving Conditions: Driving in adverse weather conditions, such as rain or snow, requires extra caution when towing. Reduced speeds and increased following distances are recommended.

Reliability and Maintenance

The reliability of a Class 4 hitch is generally high, provided it's properly installed and maintained. Regular inspection is essential to identify any signs of wear or damage. Key maintenance tips include:

- Regular Inspections: Inspect the hitch for cracks, rust, or loose bolts. Pay close attention to weld joints.

- Torque Checks: Periodically check the torque of the mounting bolts to ensure they are properly tightened. Refer to the manufacturer's specifications for torque values.

- Lubrication: Lubricate the ball mount and receiver to prevent rust and ensure smooth operation.

- Corrosion Protection: Apply touch-up paint or rust inhibitors to any areas where the coating has been damaged.

- Proper Storage: When not in use, store the hitch in a dry place to prevent corrosion.

Failure to maintain the hitch can lead to premature wear and potential failure. Regular maintenance is a critical aspect of ensuring the safety and reliability of the towing system.

Future Trends

The automotive industry is constantly evolving, and several trends are likely to impact the future of Class 4 hitches:

- Lightweight Materials: The use of lightweight materials, such as aluminum alloys and composite materials, could reduce the weight of hitches while maintaining strength.

- Integrated Towing Systems: Automakers are increasingly offering integrated towing systems with advanced features such as trailer sway control and integrated brake controllers.

- Electric Vehicles: The growth of electric vehicles (EVs) is driving the development of new towing solutions optimized for EV powertrains. EVs have unique towing considerations such as range reduction and regenerative braking compatibility.

- Smart Towing Technology: Sensor-based systems that monitor trailer weight and stability could provide real-time feedback to the driver and automatically adjust vehicle settings to optimize towing performance.

Conclusion

The Class 4 trailer hitch plays a vital role in enabling a wide range of towing applications. Automotive professionals need a thorough understanding of the technical specifications, engineering considerations, and real-world performance of these hitches to provide informed advice and service. As the automotive industry continues to evolve, innovation in materials, technology, and integration will further enhance the capabilities and safety of Class 4 hitches, ensuring they remain a valuable asset for drivers who need to tow substantial loads. The push towards electric vehicles and smart technology provides exciting opportunities for advancement and requires continuous learning and adaptation for those in the automotive field.