Cleaning Direct Injection Intake Valves

Understanding Direct Injection and the Intake Valve Problem

Direct injection (DI) engines have become increasingly common in modern vehicles due to their improved fuel efficiency and power output compared to traditional port fuel injection engines. However, this technology comes with a unique set of challenges, particularly concerning the cleanliness of intake valves. Unlike port injection systems that spray fuel upstream of the intake valves, direct injection systems inject fuel directly into the combustion chamber. This means there's no fuel washing over the intake valves to keep them clean. Consequently, carbon deposits can build up on the intake valves over time, leading to performance issues.

This article aims to provide a clear and helpful understanding of the intake valve cleaning process in direct injection engines, addressing the problem, the symptoms, and the available solutions. We'll focus on providing information that's accessible to the general public, regardless of their mechanical expertise.

Why Carbon Deposits Form on Direct Injection Intake Valves

The buildup of carbon deposits on intake valves in direct injection engines is primarily due to the absence of fuel washing the valves. Several factors contribute to this:

- Crankcase Ventilation System (PCV): The PCV system vents blow-by gases from the crankcase back into the intake manifold to be re-burned. These gases contain oil vapors and other contaminants that can condense on the intake valves.

- Oil Vapor: Even with a well-functioning PCV system, some oil vapor can still make its way into the intake manifold. This oil is exposed to high temperatures and can bake onto the valve surfaces.

- Exhaust Gas Recirculation (EGR): EGR systems recirculate exhaust gases back into the intake manifold to reduce nitrogen oxide (NOx) emissions. These exhaust gases contain soot and other particles that can contribute to carbon buildup.

- Lack of Fuel Washing: As mentioned earlier, the direct injection system doesn't spray fuel onto the intake valves, so there's no solvent action to remove these deposits.

Symptoms of Dirty Direct Injection Intake Valves

Recognizing the symptoms of carbon buildup on intake valves is crucial for timely intervention. Early detection can prevent more severe problems and potentially costly repairs. Here are some common signs:

- Reduced Fuel Economy: Carbon deposits restrict airflow into the cylinders, forcing the engine to work harder and consume more fuel.

- Rough Idling: Irregular airflow can cause the engine to idle roughly or even stall.

- Hesitation During Acceleration: The engine may hesitate or stumble when accelerating due to insufficient airflow.

- Loss of Power: Carbon deposits reduce the engine's volumetric efficiency, leading to a noticeable loss of power.

- Check Engine Light: In some cases, severe carbon buildup can trigger the check engine light, indicating a problem with the engine's air-fuel mixture or emissions.

- Increased Emissions: Carbon deposits can negatively affect combustion, leading to increased emissions of harmful pollutants.

It's important to note that these symptoms can also be caused by other issues, so it's always best to have a qualified mechanic diagnose the problem accurately.

Methods for Cleaning Direct Injection Intake Valves

Several methods are available for cleaning carbon deposits from direct injection intake valves. Each method has its pros and cons, and the best choice depends on the severity of the buildup and the vehicle's specific needs.

1. Walnut Blasting

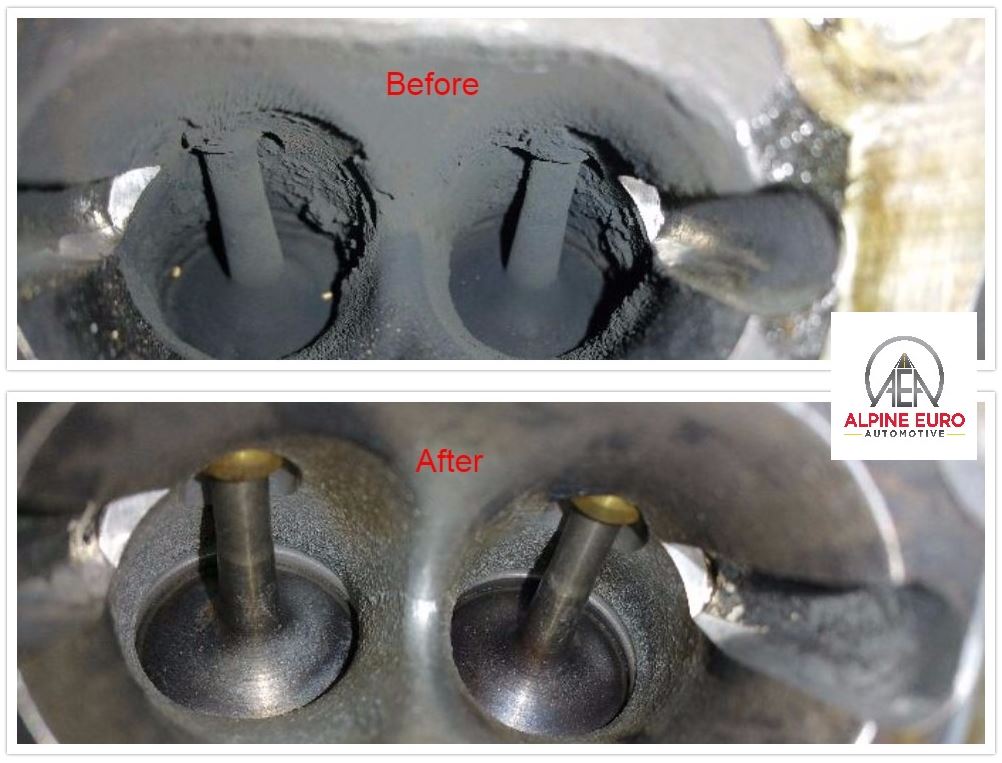

Walnut blasting is considered one of the most effective methods for cleaning intake valves. This process involves using compressed air to propel finely ground walnut shells against the valves, effectively removing carbon deposits without damaging the valve surfaces. Here's how it works:

- The intake manifold is removed to access the intake valves.

- The engine is rotated so that the valves are closed in each cylinder being cleaned.

- A special adapter is attached to the intake port.

- The walnut blasting tool is used to spray walnut shells at the valve.

- A vacuum system removes the spent walnut shells and carbon debris.

- The process is repeated for each valve.

- The intake manifold is reinstalled.

Pros: Very effective at removing carbon deposits, relatively safe for the engine, and environmentally friendly (walnut shells are biodegradable).

Cons: Requires specialized equipment and expertise, can be time-consuming, and may be more expensive than other methods.

2. Chemical Cleaning

Chemical cleaning involves using specialized solvents to dissolve carbon deposits. This method can be performed either with the engine running (using a fuel system cleaner added to the fuel tank) or with the engine off (using a spray-in cleaner directly applied to the intake valves). Direct application is much more effective.

Pros: Less expensive than walnut blasting, can be performed by DIY enthusiasts (with caution), and requires less specialized equipment.

Cons: Less effective than walnut blasting for heavy carbon buildup, some chemicals can be harsh on engine components, and proper ventilation and safety precautions are essential.

How to use a spray-in cleaner (general guidelines):

- Consult your vehicle's repair manual or a trusted mechanic for specific instructions and recommended products.

- Disconnect the intake air duct from the throttle body.

- Start the engine and allow it to idle.

- Carefully spray the cleaner directly into the throttle body, following the product's instructions. Be careful to not stall the engine. Short bursts are preferable.

- After spraying, allow the engine to idle for a specified period of time.

- Reinstall the intake air duct.

- Take the car for a drive so the cleaner can work at operating temperature.

Important Note: Always follow the manufacturer's instructions and safety precautions when using chemical cleaners. Some cleaners may not be compatible with certain engine components.

3. Intake Valve Cleaning Additives

Some fuel additives claim to clean intake valves by dissolving carbon deposits. While these additives may help prevent further buildup, they are generally not effective at removing existing heavy deposits. They are best used as a preventative measure after a thorough cleaning has been performed.

Pros: Easy to use, inexpensive, and can help prevent future carbon buildup.

Cons: Not effective at removing existing heavy deposits, and their long-term effectiveness is debatable.

Preventing Carbon Buildup on Direct Injection Intake Valves

While cleaning is necessary when carbon buildup occurs, preventative measures can significantly reduce the frequency and severity of the problem. Here are some tips to help prevent carbon buildup on direct injection intake valves:

- Use High-Quality Fuel: Using premium fuel with detergents can help keep the fuel system clean and reduce the amount of deposits that form on the intake valves.

- Consider an Oil Catch Can: An oil catch can is a device that intercepts oil vapors from the PCV system before they enter the intake manifold. This can significantly reduce the amount of oil that contaminates the intake valves.

- Regular Oil Changes: Changing your oil regularly with a high-quality synthetic oil can help reduce the amount of oil vapor that is vented into the intake manifold.

- Short Trip Avoidance: Short trips don't allow the engine to fully warm up, which can lead to increased condensation and deposit formation. Try to combine short trips or take longer routes when possible.

- Periodic Italian Tune-Ups: While not a scientifically proven method, some mechanics recommend occasionally running the engine at high RPMs for short periods to help burn off some of the carbon deposits. However, this should be done safely and responsibly.

When to Seek Professional Help

While some cleaning methods can be performed by DIY enthusiasts, it's often best to seek professional help for cleaning direct injection intake valves. A qualified mechanic has the necessary expertise, equipment, and experience to perform the job safely and effectively.

Consider seeking professional help if:

- You're not comfortable working on your engine.

- You don't have the necessary tools or equipment.

- The carbon buildup is severe.

- You're unsure about which cleaning method is best for your vehicle.

- You experience any difficulties or complications during the cleaning process.

A professional mechanic can accurately diagnose the problem, recommend the best cleaning method, and ensure that the job is done correctly, minimizing the risk of damage to your engine.

Conclusion

Carbon buildup on intake valves is a common problem in direct injection engines, but it can be effectively addressed with proper cleaning and preventative measures. By understanding the causes, symptoms, and available solutions, you can keep your engine running smoothly and efficiently for years to come. Remember to prioritize safety and consult a qualified mechanic if you're unsure about any aspect of the cleaning process. Regular maintenance and preventative measures are key to avoiding costly repairs down the road. Don't neglect your DI engine!