Clutch On Car Air Conditioner

The air conditioning (AC) system in your car is a complex network of components working together to keep you cool and comfortable. A crucial part of this system is the AC clutch, a mechanism that engages and disengages the compressor, allowing it to pump refrigerant and cool the air. Understanding the AC clutch's function, common issues, and maintenance practices can save you time, money, and discomfort. This article provides a practical guide for car owners and mechanics on diagnosing and addressing AC clutch problems.

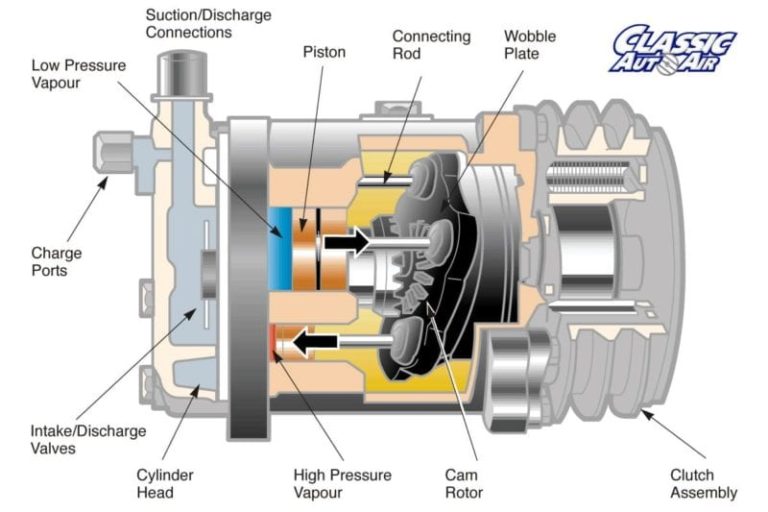

Understanding the AC Clutch

The AC clutch is an electromagnetic device that connects the compressor pulley to the compressor shaft. When the AC is turned on, an electrical current flows through the clutch coil, creating a magnetic field. This magnetic field pulls the clutch plate towards the pulley, engaging the compressor and allowing it to start pumping refrigerant. When the AC is turned off, the electrical current stops, the magnetic field collapses, and the clutch disengages, stopping the compressor.

Components of the AC Clutch

The AC clutch assembly typically consists of the following parts:

- Pulley: This is driven by the engine's serpentine belt and spins continuously when the engine is running.

- Clutch Plate (or Armature Plate): This is the part that engages with the pulley to drive the compressor shaft. It has a friction surface that contacts the pulley.

- Electromagnet Coil (or Stator Coil): This coil creates the magnetic field that pulls the clutch plate towards the pulley.

- Air Gap: The small space between the clutch plate and the pulley when the AC is off. This gap is critical for proper clutch operation.

Common AC Clutch Problems: Symptoms, Causes, and Solutions

1. AC Not Cooling

Symptom: The AC system blows warm air, or no air at all, even when set to the coldest setting.

Possible Causes:

- Faulty AC Clutch: The clutch is not engaging, preventing the compressor from pumping refrigerant. This could be due to a failed coil, excessive air gap, or damaged clutch plate.

- Low Refrigerant Level: Insufficient refrigerant prevents the compressor from operating efficiently.

- Electrical Issues: Problems with the wiring, relay, or AC control switch can prevent the clutch from receiving power.

- Compressor Failure: The compressor itself may be faulty, even if the clutch is working.

Troubleshooting and Solutions:

- Check the Clutch Engagement: With the engine running and the AC on, observe the AC clutch. Does it engage (spin with the pulley) or remain stationary? If it doesn't engage, proceed to the next steps.

- Check for Power at the Clutch: Use a multimeter to check for voltage at the clutch connector when the AC is turned on. If there's no voltage, investigate the wiring, relay, fuse, and AC control switch. Consult your car's wiring diagram. For example, on a Honda Civic, a faulty AC relay is a common cause of this issue. Replacing the relay might solve the problem.

- Check the Air Gap: Use a feeler gauge to measure the air gap between the clutch plate and the pulley. The recommended air gap is typically between 0.020 and 0.040 inches (0.5 to 1.0 mm). An excessively large air gap can prevent the clutch from engaging, even with sufficient voltage. Adjusting the air gap often involves removing shims from the clutch plate. On some Ford F-150 models, shimming the clutch is a routine maintenance item.

- Inspect the Clutch Coil: If power is reaching the clutch but it still doesn't engage, the coil may be faulty. Use a multimeter to check the coil's resistance. An open circuit (infinite resistance) indicates a failed coil. Replacing the clutch assembly (or just the coil if possible) is necessary.

- Check Refrigerant Level: Use AC manifold gauges to check the refrigerant pressure. If the pressure is low, recharge the system. However, address any leaks first, as simply recharging a leaking system is a temporary fix.

2. Clutch Slipping or Noisy Operation

Symptom: The AC clutch makes a squealing or grinding noise, or the AC cools intermittently.

Possible Causes:

- Worn Clutch Plate: The friction surface on the clutch plate is worn, causing it to slip and produce noise.

- Excessive Air Gap: A large air gap requires the electromagnet to work harder, leading to slippage and noise.

- Damaged Pulley Bearing: A worn bearing in the pulley can cause noise and prevent the clutch from engaging smoothly.

- Contamination: Dirt, oil, or other contaminants on the clutch surfaces can cause slippage and noise.

Troubleshooting and Solutions:

- Inspect the Clutch Plate: Visually inspect the clutch plate for wear, damage, or contamination. If the friction surface is worn thin or glazed, the clutch assembly needs to be replaced.

- Check the Air Gap: As mentioned earlier, ensure the air gap is within the specified range. Adjust as needed.

- Listen for Pulley Bearing Noise: With the engine running and the AC off, listen carefully to the pulley. If you hear a grinding or rumbling noise, the bearing is likely worn. The pulley and bearing assembly should be replaced. A mechanic's stethoscope can be helpful for pinpointing the source of the noise.

- Clean the Clutch Surfaces: If the clutch surfaces are contaminated, use a clean cloth and brake cleaner to remove the contaminants. Be careful not to get brake cleaner on other parts of the AC system.

3. Clutch Engages and Disengages Repeatedly (Cycling)

Symptom: The AC clutch engages and disengages rapidly, causing the AC to blow cool air intermittently.

Possible Causes:

- Low Refrigerant Level: The low-pressure switch detects low refrigerant and cycles the compressor to protect it from damage.

- Faulty Low-Pressure Switch: The switch itself may be malfunctioning, even if the refrigerant level is adequate.

- Electrical Issues: Intermittent electrical problems can cause the clutch to cycle on and off.

- Overheating: The compressor may be overheating, causing a high-pressure switch to cycle the clutch.

Troubleshooting and Solutions:

- Check Refrigerant Level: Use AC manifold gauges to check the refrigerant pressure. If the pressure is low, recharge the system and address any leaks.

- Test the Low-Pressure Switch: Use a multimeter to test the low-pressure switch for continuity. If the switch is open even when the refrigerant pressure is adequate, it may be faulty and need to be replaced.

- Check for Electrical Issues: Inspect the wiring and connectors for corrosion or damage. Use a multimeter to check for voltage drops in the circuit.

- Check for Overheating: Ensure the condenser is clean and free of debris. A clogged condenser can cause the compressor to overheat. Also, check the cooling fan operation.

Preventative Maintenance for the AC Clutch

Regular maintenance can help prevent AC clutch problems and extend the life of your AC system.

- Regular AC System Check: Have your AC system inspected annually by a qualified technician. This includes checking the refrigerant level, inspecting the clutch, and testing the system's performance.

- Belt Inspection: Inspect the serpentine belt regularly for wear, cracks, or fraying. A worn belt can slip, causing the AC clutch to engage improperly. Replace the belt as needed.

- Clean the Condenser: Keep the condenser clean and free of debris. A clogged condenser restricts airflow and can cause the compressor to overheat.

- Proper Refrigerant Charge: Maintain the proper refrigerant charge. Overcharging or undercharging the system can damage the compressor and other components.

- Listen for Unusual Noises: Pay attention to any unusual noises coming from the AC system. Early detection of problems can prevent more serious damage.

Real-World Examples

- Toyota Camry: A common issue with older Camrys is a failing AC clutch coil. Replacing the coil is often a more cost-effective solution than replacing the entire compressor.

- Chevrolet Silverado: The AC clutch on Silverados can be prone to slippage due to excessive air gap. Adjusting the air gap by removing shims can often resolve this issue.

- Jeep Wrangler: Wranglers often experience AC problems due to off-road driving. Mud and debris can contaminate the clutch surfaces, leading to slippage and noise. Regular cleaning of the clutch is important.

Conclusion

The AC clutch is a vital component of your car's air conditioning system. By understanding its function, common problems, and maintenance practices, you can keep your AC system running smoothly and efficiently. Regular inspections, prompt repairs, and proper maintenance will ensure that you stay cool and comfortable on the road. Don't neglect your AC system; addressing small issues early can prevent costly repairs down the line. Remember to consult your car's service manual for specific maintenance recommendations and troubleshooting procedures. For complex AC problems, always seek the assistance of a qualified automotive technician.