Constant Velocity Joint Replacement Cost

Alright, let's talk about CV joint replacement cost. It's a topic that comes up frequently, especially with vehicles that are front-wheel drive or all-wheel drive. As someone who's likely turned a wrench or two yourself, you know that understanding the components and labor involved is crucial for budgeting and making informed decisions.

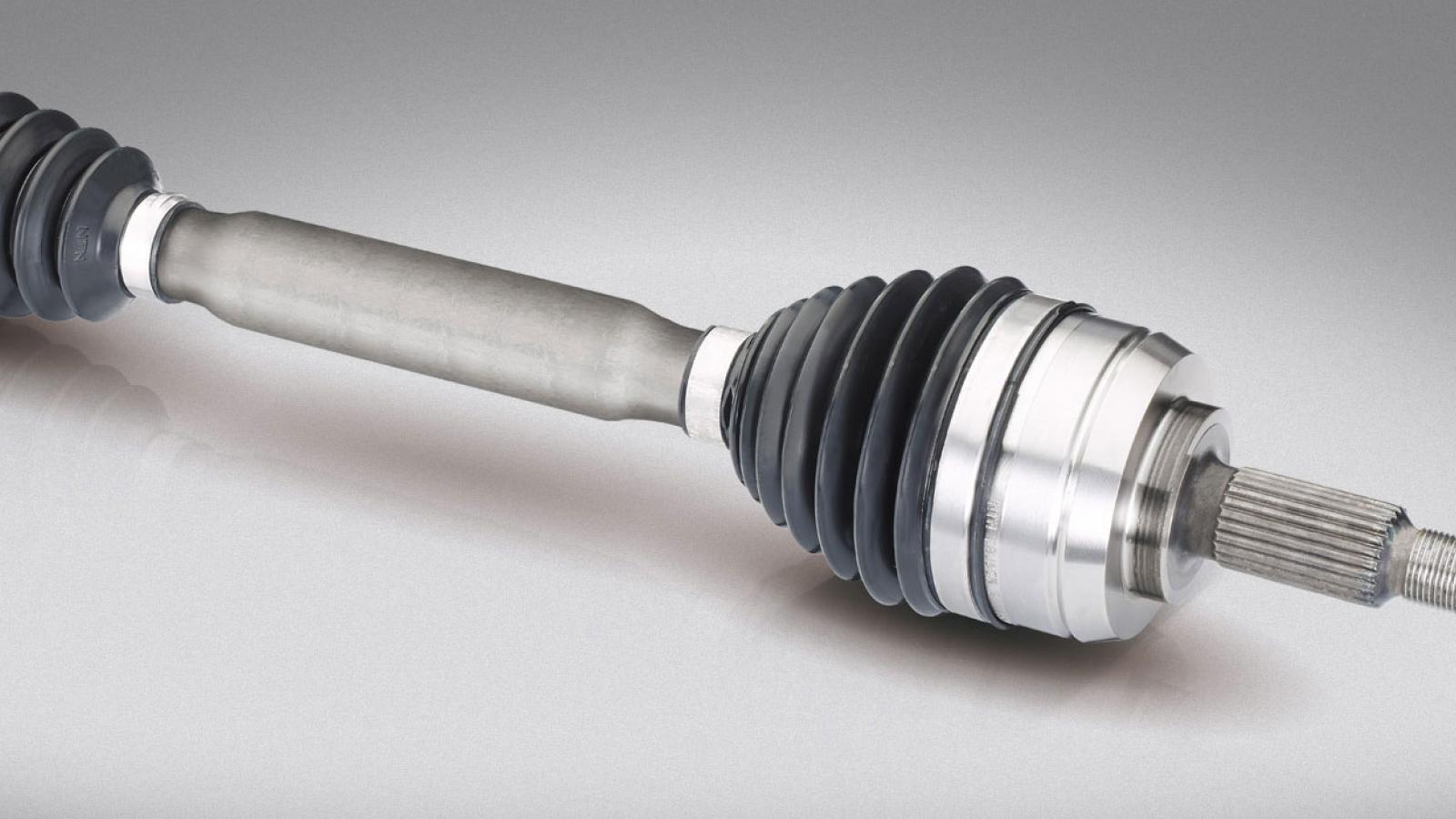

Understanding Constant Velocity (CV) Joints

Before we dive into the cost, let's quickly recap what CV joints are and why they're so vital. A CV joint, or Constant Velocity joint, is a type of flexible coupling that allows a rotating shaft to transmit power through a variable angle without significant changes in rotational speed. Think of it as a universal joint (U-joint), but much smoother at higher angles. They're primarily found in front-wheel drive (FWD) vehicles at the drive axles, connecting the transmission to the wheels. You'll also find them in all-wheel drive (AWD) and independent rear suspension (IRS) vehicles.

Specifically, you'll find two CV joints on each axle: an inner CV joint, which connects to the transmission (or differential in the case of a rear axle) and an outer CV joint, which connects to the wheel hub. The outer joint allows for the wheel to turn left and right, while both joints compensate for suspension travel, ensuring constant power delivery to the wheels regardless of steering angle or road conditions.

There are a few different types of CV joints. The most common are:

- Rzeppa Joint: This is the most common type, using ball bearings within a cage to transmit power.

- Tripod Joint: Often used as the inner joint, this type uses three rollers that slide within a housing, allowing for axial movement as well as angular movement.

When a CV joint fails, it's usually due to grease leakage and subsequent contamination by dirt and debris. The grease keeps the joint lubricated and cool, but if the protective boot tears or cracks, the grease escapes and contaminants enter, leading to accelerated wear and eventual failure. Typical symptoms of a failing CV joint include clicking or popping noises, especially when turning. You might also experience vibrations, particularly at higher speeds. Don't ignore these signs, as a completely failed CV joint can leave you stranded and can potentially damage other suspension components.

Factors Affecting CV Joint Replacement Cost

Now, let's get down to the brass tacks: the cost. Several factors influence the price of a CV joint replacement, and understanding them will help you estimate the expenses involved.

1. Type of Replacement

You generally have three options for replacing a CV joint:

- Complete Axle Assembly: This is often the easiest and most common route. It involves replacing the entire axle shaft, including both inner and outer CV joints. While it might seem more expensive upfront, it saves time on labor and ensures that all components are new and properly matched. This is generally recommended if the axle itself has significant wear or damage.

- Individual CV Joint Replacement: This involves replacing only the damaged CV joint (either inner or outer). This can be a cheaper option if only one joint is failing and the axle itself is in good condition. However, it requires more labor and specialized tools. This is a more DIY friendly option if you're comfortable working with presses and separating joints.

- Rebuilt CV Joint/Axle: Rebuilt axles are core exchanges, where old axles are refurbished and resold. They are a good middle-ground between the cost of a brand new part and the increased labor of only replacing one joint.

2. Part Cost

The cost of the CV joint or axle assembly itself varies significantly depending on the vehicle's make, model, and year. Aftermarket parts are often cheaper than OEM (Original Equipment Manufacturer) parts, but the quality can vary. It's essential to research reputable brands and read reviews before opting for the cheapest option. A good rule of thumb is to stick with known brands, even if they cost a bit more. Some reputable brands include GSP, Cardone, and Moog.

Expect to pay anywhere from $50 to $300 for a single CV joint, and $100 to $500+ for a complete axle assembly, depending on the factors mentioned above. High-performance vehicles or those with specialized axles (e.g., heavy-duty trucks) will typically have higher part costs.

3. Labor Cost

Labor costs can also vary significantly depending on your location, the shop's hourly rate, and the complexity of the job. Replacing an entire axle assembly is generally less labor-intensive than replacing a single CV joint, which requires removing the axle, disassembling the joint, and pressing the new joint onto the shaft. Book time for this job ranges from 1 to 3 hours per side. At a shop rate of $100-$150/hr, labor can add $100 - $450 per axle.

4. Vehicle Complexity

Some vehicles are simply more difficult to work on than others. For example, vehicles with limited access to the axle assembly or those with complex suspension systems may require more labor time, increasing the overall cost. Rust is another big factor - seized bolts and corroded components can dramatically increase labor time, as mechanics may need to use penetrating oil, heat, or even specialized tools to remove parts without damaging them. Vehicles with complex electronic systems, such as those with electronic stability control (ESC) or anti-lock braking systems (ABS), may require additional diagnostic procedures, which can also add to the cost.

5. Location, Location, Location

Labor costs vary greatly depending on where you live. Mechanics in larger cities with higher costs of living often charge more per hour. Expect to pay more for the same job in a major metropolitan area compared to a rural area.

DIY vs. Professional Replacement

If you're a seasoned DIYer with the right tools and experience, you might consider replacing the CV joint yourself. This can save you a significant amount on labor costs. However, it's essential to be realistic about your skills and abilities. This job involves working with suspension components, which can be dangerous if not handled properly. You'll need a good set of tools, including a socket set, wrenches, a torque wrench, a ball joint separator (pickle fork or ball joint press), and possibly a slide hammer. A shop press is almost essential for replacing an individual CV joint.

Safety is paramount. Always use jack stands to support the vehicle securely, and wear appropriate safety gear, including eye protection and gloves. Follow the manufacturer's instructions carefully and consult a repair manual or online resources if you're unsure about any step. If you're not comfortable with any aspect of the job, it's best to leave it to a professional.

Estimating the Total Cost

To get a rough estimate of the total cost, consider the following breakdown:

- Part Cost: $50 - $500+ (depending on the type of replacement and the vehicle)

- Labor Cost: $100 - $450 (depending on the complexity of the job and the shop's hourly rate)

- Miscellaneous Costs: $20 - $50 (for grease, penetrating oil, and other consumables)

Therefore, the total cost of CV joint replacement can range from $170 to $950+ per axle. Getting quotes from multiple shops is always a good idea to compare prices and services. Be sure to ask about the warranty offered on the parts and labor.

Preventative Maintenance

While replacement is sometimes unavoidable, you can extend the life of your CV joints with proper maintenance. Periodically inspect the CV joint boots for any signs of damage, such as cracks or tears. If you find any damage, replace the boot immediately to prevent grease leakage and contamination. Avoid driving aggressively, especially when turning, as this puts extra stress on the CV joints. Following these simple tips can help you avoid costly repairs down the road.

Final Thoughts

CV joint replacement is a common repair, especially on vehicles with front-wheel drive or all-wheel drive. Understanding the factors that influence the cost, such as the type of replacement, the part cost, the labor cost, and the vehicle's complexity, will help you budget for the repair and make informed decisions. Whether you choose to tackle the job yourself or leave it to a professional, be sure to prioritize safety and quality to ensure a long-lasting repair. Good luck!