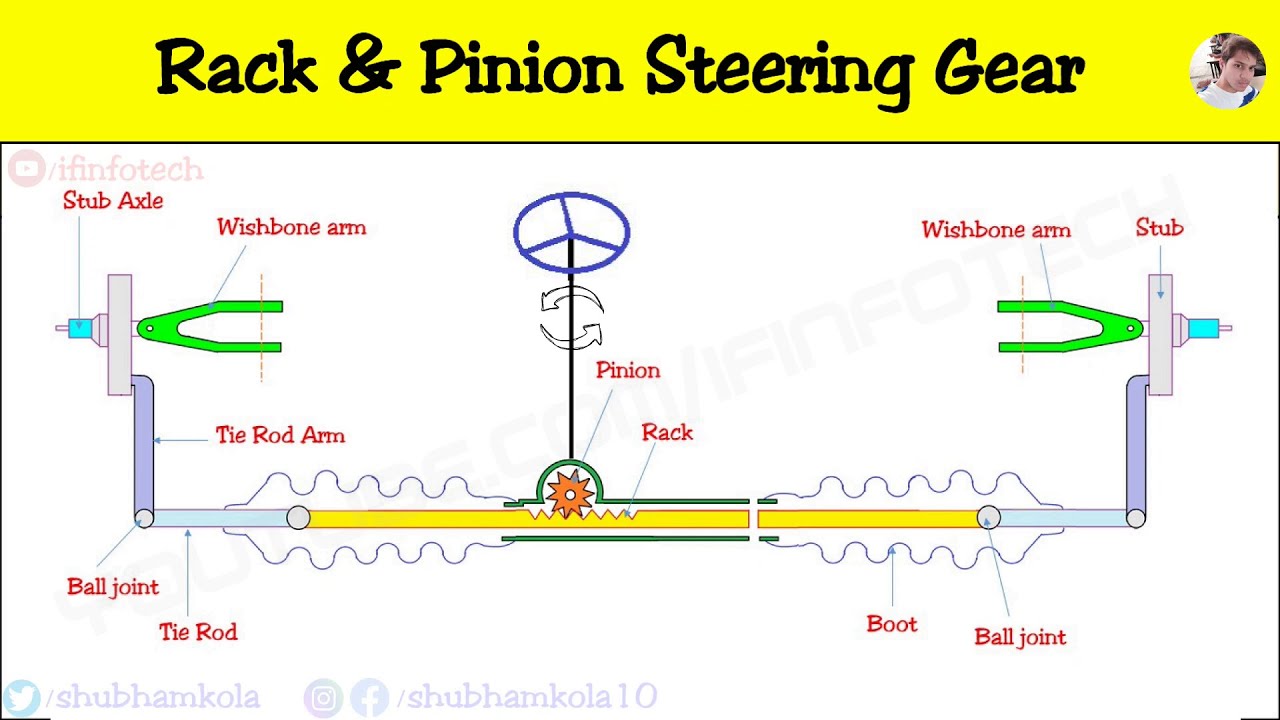

Diagram Of A Rack And Pinion

Alright, let's dive deep into the heart of your steering system: the rack and pinion. This is a crucial component that translates the rotational motion of your steering wheel into the linear motion that steers your wheels. Whether you're experiencing steering issues or planning an upgrade, understanding its mechanics is key.

The Core Components

At its simplest, a rack and pinion system consists of two primary parts:

- The Pinion Gear: A small, circular gear attached to the steering shaft. It's what *you* control when you turn the steering wheel.

- The Rack: A linear toothed bar that meshes with the pinion gear. Think of it as a long, straight gear.

But that's just the beginning. A complete rack and pinion system has several other important components that work together seamlessly. Let's break them down:

Detailed Breakdown

- Steering Shaft: This connects your steering wheel to the pinion gear. It's usually comprised of one or more sections joined by universal joints (U-joints) to allow for angular movement and accommodate the vehicle's design. Consider it the communication line between your hands and the steering mechanism.

- Pinion Gear Housing: This sturdy housing supports the pinion gear and its bearings. It's designed to withstand the significant forces generated during steering. Inside, you'll find:

- Pinion Bearings: These allow the pinion gear to rotate smoothly and freely within the housing, minimizing friction and wear. They are typically ball or tapered roller bearings for handling both radial and axial loads.

- Seals: These prevent lubricant leakage and keep contaminants out of the pinion gear housing, protecting the bearings and ensuring proper operation.

- Rack Housing: This houses the rack itself and provides a rigid structure for it to slide within. It's often made of high-strength steel or aluminum. Inside the rack housing, you'll typically find:

- Rack Bushings (or Bearings): These support the rack and allow it to slide smoothly and precisely within the housing. They are crucial for maintaining steering accuracy and preventing play. Worn bushings are a common cause of loose steering.

- Seals: Like in the pinion housing, seals prevent fluid leakage and protect the rack from dirt and debris.

- Tie Rods: These connect the ends of the rack to the steering knuckles (also known as spindle or hub carrier) on the wheels. They transmit the linear motion of the rack to the wheels, causing them to turn. Tie rods are typically adjustable to allow for precise wheel alignment.

- Tie Rod Ends: These are ball joints that connect the tie rods to the steering knuckles. They allow for articulation as the wheels turn and the suspension moves up and down. Tie rod ends are wear items and should be inspected regularly for play.

- Bellows Boots (or Dust Boots): These rubber boots protect the tie rod ends and the ends of the rack from dirt, moisture, and debris. Keeping these boots intact is essential for extending the life of the steering components.

- Power Steering Components (If Applicable): Many modern vehicles use power steering to reduce the effort required to turn the steering wheel. This typically involves:

- Power Steering Pump: This pump, usually driven by the engine via a belt, provides hydraulic pressure to assist the steering.

- Hydraulic Lines: These hoses carry the pressurized hydraulic fluid from the pump to the rack and pinion unit.

- Rotary Valve (or Control Valve): Located on the pinion housing, this valve directs hydraulic fluid to either side of the rack based on the direction you're turning the steering wheel. More fluid to the left means the rack moves left, assisting you in turning left.

- Hydraulic Cylinder (Inside Rack Housing): Integrated within the rack housing, this cylinder uses hydraulic pressure to move the rack, significantly reducing the effort you need to apply to the steering wheel.

How It Works: From Wheel to Wheels

The beauty of the rack and pinion system lies in its simplicity and efficiency. Here's the step-by-step process:

- You Turn the Steering Wheel: This rotates the steering shaft, which in turn rotates the pinion gear.

- Pinion Engages the Rack: As the pinion gear rotates, its teeth mesh with the teeth on the rack.

- Rack Moves Linearly: The rotation of the pinion forces the rack to move either left or right, depending on the direction you turned the steering wheel.

- Motion Transferred to Wheels: The linear motion of the rack is transmitted through the tie rods and tie rod ends to the steering knuckles, causing the wheels to turn.

- Power Steering Assistance (If Equipped): If your vehicle has power steering, the rotary valve senses the direction you're turning the wheel and directs hydraulic fluid to assist the rack's movement, making steering much easier.

Understanding Steering Ratio

The steering ratio is a critical parameter that defines the relationship between the steering wheel rotation and the resulting wheel deflection. It's expressed as a ratio, such as 16:1 or 13:1. A lower ratio (e.g., 13:1) means that for every 13 degrees of steering wheel rotation, the wheels turn 1 degree. This results in quicker steering response but requires more effort. A higher ratio (e.g., 16:1) means that for every 16 degrees of steering wheel rotation, the wheels turn 1 degree. This provides slower steering response but requires less effort.

Modifying the steering ratio is a common modification for enthusiasts. A quicker ratio can improve handling and responsiveness, especially in performance driving situations. However, it can also make the car feel twitchier and require more precise steering inputs.

Common Issues and Troubleshooting

Like any mechanical system, the rack and pinion is susceptible to wear and tear. Here are some common problems and how to diagnose them:

- Loose Steering: This can be caused by worn tie rod ends, loose rack bushings, or excessive play in the pinion gear. To diagnose, have someone rock the steering wheel back and forth while you inspect the tie rod ends and rack bushings for movement.

- Power Steering Fluid Leak: This is often caused by damaged hydraulic lines, leaky seals in the rack housing, or a failing power steering pump. Check for fluid stains near these components.

- Stiff Steering: This can be caused by a failing power steering pump, a clogged hydraulic line, or a seized rotary valve. Start by checking the power steering fluid level and the condition of the belt driving the pump.

- Knocking or Clunking Noises: These noises can indicate worn tie rod ends, loose rack bushings, or a failing rack and pinion unit. Pay close attention to the sounds as you turn the steering wheel.

- Uneven Tire Wear: Can be a symptom of misaligned wheels, often caused by damaged or worn tie rods.

Maintenance and Care

Proper maintenance can significantly extend the life of your rack and pinion system:

- Regular Inspections: Visually inspect the steering components for signs of wear, damage, or leaks during routine maintenance.

- Grease Fittings: Some tie rod ends and rack bushings have grease fittings (zerks). Lubricate them regularly with a quality grease gun.

- Power Steering Fluid: Check and top off the power steering fluid regularly. Use the correct type of fluid recommended by your vehicle manufacturer. Periodically, usually every two years or 30,000 miles, the power steering fluid should be completely flushed and replaced. This removes contaminants and ensures optimal performance.

- Wheel Alignment: Maintain proper wheel alignment to prevent excessive wear on the steering components and tires. After replacing any steering or suspension component, getting a wheel alignment is crucial.

- Replace Worn Components Promptly: Address any steering issues promptly to prevent further damage and ensure your safety.

Rack and Pinion Replacement: When to Bite the Bullet

Sometimes, despite your best efforts, the rack and pinion unit itself will need to be replaced. Signs that point to replacement include:

- Excessive Internal Wear: If there's significant play within the rack housing, even after replacing bushings, the rack itself is likely worn.

- Severe Leaks: If you have persistent power steering fluid leaks that cannot be fixed by replacing seals, the rack may be corroded or damaged internally.

- Unrepairable Damage: Physical damage to the rack housing or pinion gear housing warrants replacement.

Replacing a rack and pinion is a moderately complex job that often requires specialized tools, especially for disconnecting the hydraulic lines in power steering systems. Unless you're experienced with automotive repair, it's best left to a professional. However, with the right knowledge and tools, a capable DIYer can tackle this project.

Understanding the rack and pinion system empowers you to diagnose steering problems, perform necessary maintenance, and make informed decisions about repairs or upgrades. Safe driving starts with a properly functioning steering system!