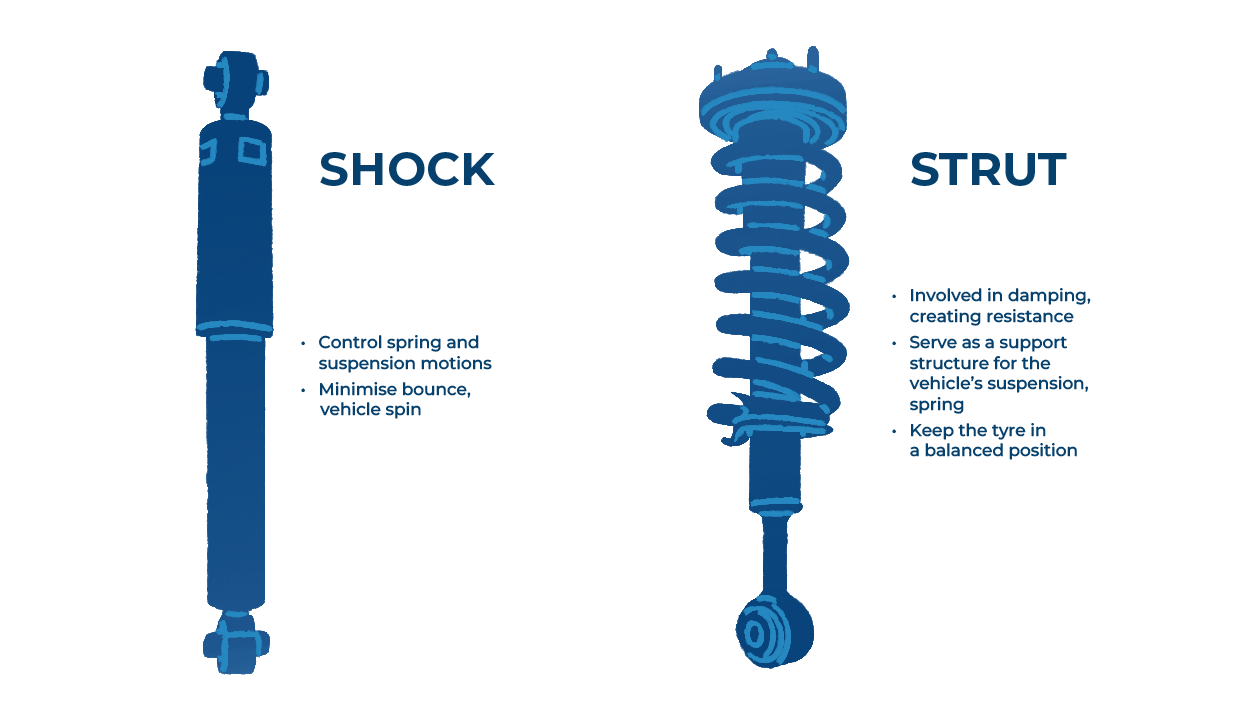

Diagram Of Shocks And Struts

The humble shock absorber and strut, often relegated to the background of automotive discussions, are on the cusp of a radical transformation. As the automotive industry hurtles toward electrification, advanced driver-assistance systems (ADAS), and increasingly personalized driving experiences, these unsung heroes of ride quality are set to become smarter, more adaptable, and integral to the overall vehicle performance. Forget the basic coil-over setup; we're entering an era of electronically controlled, predictive, and even self-healing suspension systems.

The Electric Revolution: A New Demand on Dampers

The shift to electric vehicles (EVs) presents both opportunities and challenges for shock and strut technology. EVs, with their instant torque and often heavier battery packs, place significantly different demands on suspension systems compared to their internal combustion engine (ICE) counterparts. The increased weight necessitates more robust damping to control body roll and maintain stability, particularly during acceleration and regenerative braking. Consider the raw power delivery of a Tesla Model S Plaid - traditional shock absorbers would struggle to provide the necessary control without compromising ride comfort.

Moreover, the silent nature of EVs amplifies the perception of road noise and vibrations. This heightened sensitivity demands more sophisticated noise, vibration, and harshness (NVH) control from the suspension system. Engineers are exploring adaptive damping technologies that can actively counteract road irregularities and minimize unwanted vibrations transmitted to the cabin. Expect to see a wider adoption of magnetorheological (MR) dampers, which use a fluid whose viscosity can be controlled by a magnetic field. This allows for near-instantaneous adjustments to damping force based on road conditions and driving style.

Predictive suspension systems are also gaining traction in the EV space. These systems utilize sensors, cameras, and GPS data to anticipate upcoming road imperfections and proactively adjust the dampers before the vehicle encounters the bump or pothole. Imagine a vehicle that "sees" a pothole ahead and instantly stiffens the suspension to minimize impact and maintain a smooth ride. This level of proactive control not only enhances comfort but also improves vehicle handling and safety.

Challenges of EV Suspension: Weight and Range

However, the integration of advanced damping technologies into EVs is not without its hurdles. MR dampers, while highly effective, are more complex and expensive than traditional dampers. Their increased weight can also negatively impact the vehicle's overall efficiency and range, a critical consideration for EV owners. Furthermore, the power consumption of electronically controlled systems needs to be carefully managed to avoid significantly draining the battery.

Manufacturers are actively addressing these challenges through material science and innovative design. Lightweight materials like aluminum and composites are being incorporated into shock and strut construction to minimize weight. Sophisticated algorithms are being developed to optimize the energy consumption of adaptive damping systems, ensuring that they only draw power when needed.

Hybrid Systems: Bridging the Gap with Intelligent Damping

Hybrid vehicles, with their combination of electric and gasoline power, present a unique set of demands on suspension systems. They require damping solutions that can seamlessly transition between different driving modes and energy regeneration strategies. For instance, during regenerative braking, the suspension needs to provide additional support to counteract the deceleration forces and maintain vehicle stability. Similarly, when switching between electric and gasoline power, the suspension needs to adapt to the changing weight distribution and power delivery characteristics.

Adaptive dampers play a crucial role in optimizing the performance of hybrid vehicles. By continuously adjusting the damping force based on driving conditions and energy management strategies, they can ensure a smooth and efficient ride. Some hybrid vehicles are even equipped with electronically controlled air suspension systems that can adjust the ride height to improve aerodynamics and fuel economy at higher speeds.

Smart Automotive Solutions: The Rise of Connected Suspension

The future of shock and strut technology is inextricably linked to the broader trend of smart automotive solutions. As vehicles become increasingly connected and autonomous, suspension systems will evolve from passive components to active participants in the overall vehicle control system. Imagine a scenario where the suspension system is integrated with the ADAS suite, providing real-time feedback on road conditions and vehicle dynamics. This information could be used to optimize the performance of other safety systems, such as electronic stability control (ESC) and automatic emergency braking (AEB).

Cloud connectivity will also play a significant role in the future of suspension technology. Vehicles will be able to share data about road conditions and suspension performance with a central server. This data could be used to create real-time maps of road hazards, allowing vehicles to proactively adjust their suspension settings to avoid potential damage. Furthermore, cloud-based diagnostics could enable predictive maintenance, alerting drivers to potential suspension issues before they become major problems.

One fascinating development is the exploration of self-healing materials for shock absorber components. Researchers are investigating polymers and other materials that can automatically repair minor damage, extending the lifespan of the suspension system and reducing maintenance costs. While still in its early stages, this technology has the potential to revolutionize the automotive industry.

Challenges of Smart Suspension: Data Security and Reliability

The increasing complexity and connectivity of suspension systems also raise concerns about data security and reliability. The potential for hackers to compromise the vehicle's control systems is a serious threat that needs to be addressed. Manufacturers must implement robust security measures to protect against unauthorized access and ensure the integrity of the suspension system.

Furthermore, the reliability of electronically controlled components in harsh automotive environments is a constant challenge. Shock absorbers are subjected to extreme temperatures, vibrations, and road debris. Manufacturers must design and test these components to ensure that they can withstand these conditions and provide reliable performance over the vehicle's lifespan.

The Road Ahead: A Vision of Seamless Mobility

The evolution of shock and strut technology is not simply about improving ride comfort or handling performance. It's about creating a more seamless and intuitive driving experience. As vehicles become increasingly autonomous, the suspension system will play an even more critical role in ensuring passenger safety and comfort. Imagine a future where vehicles can effortlessly navigate any terrain, providing a smooth and stable ride regardless of road conditions. This vision requires a holistic approach to vehicle design, where the suspension system is seamlessly integrated with other advanced technologies, such as artificial intelligence (AI) and machine learning (ML).

The challenges are real, from managing weight and energy consumption to ensuring data security and reliability. But the potential rewards – safer, more comfortable, and more efficient vehicles – are too great to ignore. By embracing innovation and collaborating across disciplines, the automotive industry can unlock the full potential of shock and strut technology and create a truly transformative driving experience. We are on the cusp of a new era of mobility, where the seemingly simple shock absorber becomes a sophisticated and intelligent component, paving the way for a future of seamless and personalized transportation.