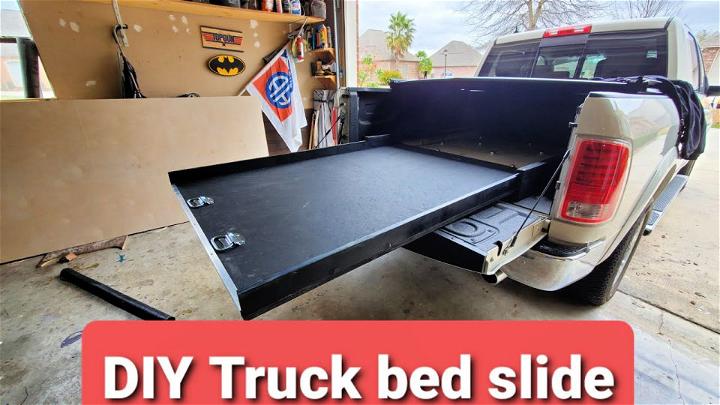

Diy Truck Bed Slide Out Rails

Truck bed slide-out rails are rapidly gaining popularity among automotive enthusiasts and professionals alike, offering an efficient solution for accessing cargo stored in the truck bed. While commercially available options offer integrated designs and advanced features, building your own DIY truck bed slide-out rails presents a cost-effective and customizable alternative. However, approaching this project requires a thorough understanding of the technical aspects, engineering principles, and potential trade-offs involved.

DIY vs. Commercial Options: A Detailed Comparison

Choosing between a DIY and a commercial truck bed slide-out system hinges on factors such as budget, skill level, and desired features. Commercial systems offer the advantage of pre-engineered designs, robust construction with high-quality materials (typically steel or aluminum), and integrated features like locking mechanisms, tie-down points, and weatherproofing. They are thoroughly tested for load capacity and durability, ensuring a reliable and safe solution. Brands like Decked, BedSlide, and CargoGlide are known for their quality and features. However, these systems can be quite expensive, often costing upwards of $1,000 or even $2,000 depending on the size and features.

DIY slide-out rails, on the other hand, offer significant cost savings and allow for complete customization to fit specific needs and truck bed dimensions. The materials can be sourced from local hardware stores or metal suppliers, and the design can be tailored to accommodate specific cargo requirements. However, the onus is on the builder to ensure structural integrity, load capacity, and safety. This requires careful planning, precise fabrication, and a solid understanding of engineering principles.

Technical Specifications and Engineering Choices

Material Selection

The choice of materials is paramount for a durable and reliable DIY slide-out system. Steel offers excellent strength and load-bearing capacity but is susceptible to rust and corrosion. Using a high-quality steel alloy and applying a durable coating like powder coating or bed liner material is crucial for longevity. Aluminum is lighter than steel and corrosion-resistant but is generally more expensive and may require specialized welding techniques. The aluminum alloy used should be carefully selected based on its strength-to-weight ratio and weldability. Common alloys include 6061 and 5052.

Rail and Bearing Design

The rails are the backbone of the slide-out system, and their design directly impacts the load capacity and smoothness of operation. Several types of rails can be used, including:

- Heavy-duty drawer slides: These are commercially available slides designed for heavy loads and feature roller bearings or ball bearings for smooth movement. They are relatively easy to install but can be more expensive than other options.

- Steel tubing and rollers: This approach involves using square or rectangular steel tubing as the rails and incorporating rollers or bearings that glide within the tubing. This method can be very strong but requires precise alignment and fabrication.

- Angle iron and UHMW (Ultra-High Molecular Weight) plastic: Angle iron provides structural support, while UHMW plastic strips act as the sliding surface. UHMW offers excellent wear resistance and low friction but may require periodic replacement depending on the load and usage.

The choice of bearings or sliding surfaces is equally important. Roller bearings offer smooth movement and high load capacity, while ball bearings are suitable for lighter loads and require less maintenance. UHMW plastic provides a cost-effective and durable sliding surface, but it may generate more friction than bearings. Regardless of the choice, ensuring proper lubrication and alignment is essential for smooth and reliable operation.

Frame Construction

The frame provides the structural support for the slide-out system and must be designed to withstand the expected loads. A robust frame can be constructed from welded steel or aluminum tubing, depending on the material choice. Reinforcements, such as gussets or cross members, should be incorporated to prevent bending or twisting under load. The frame should also be securely attached to the truck bed using bolts or welding. Using existing bed mounting points will reduce the need for custom drilling and maintain structural integrity.

Locking Mechanisms

A locking mechanism is crucial to prevent the slide-out from unintentionally rolling out during transit or when parked on an incline. Simple latching mechanisms or more sophisticated locking pins can be used. The locking mechanism should be easily accessible and robust enough to withstand repeated use and potential impacts.

Real-World Performance and Reliability

The performance of a DIY truck bed slide-out system depends heavily on the quality of materials, the precision of fabrication, and the attention to detail during assembly. A well-designed and properly built system can provide years of reliable service. However, several factors can impact performance and reliability:

- Load capacity: Exceeding the designed load capacity can lead to premature wear, bending of the rails, or failure of the bearings. It is crucial to accurately estimate the expected load and design the system accordingly.

- Environmental factors: Exposure to harsh weather conditions, such as rain, snow, and salt, can accelerate corrosion and degrade the bearings or sliding surfaces. Regular maintenance and lubrication are essential to mitigate these effects.

- Vibration and impact: Off-road driving or rough road conditions can subject the slide-out system to significant vibration and impact, which can loosen fasteners, damage bearings, or cause the frame to crack. Regular inspections and maintenance are crucial to identify and address any potential issues.

Maintenance Tips

To ensure the longevity and reliability of a DIY truck bed slide-out system, regular maintenance is essential. This includes:

- Lubrication: Regularly lubricate the bearings or sliding surfaces with a suitable lubricant to reduce friction and prevent wear. Use a lubricant specifically designed for the chosen bearing type or sliding surface.

- Inspection: Periodically inspect the rails, frame, and locking mechanism for any signs of damage, wear, or corrosion. Address any issues promptly to prevent further deterioration.

- Cleaning: Keep the slide-out system clean and free from debris, such as dirt, dust, and leaves. These contaminants can accelerate wear and reduce the smoothness of operation.

- Fastener tightening: Regularly check and tighten all fasteners, such as bolts and screws, to ensure that the system remains securely assembled.

- Corrosion protection: If using steel, regularly inspect for rust and apply touch-up paint or corrosion inhibitors as needed.

Future Trends

The market for truck bed accessories is constantly evolving, and several trends are likely to impact the design and functionality of both commercial and DIY slide-out systems. These include:

- Advanced materials: The use of lightweight, high-strength materials, such as carbon fiber composites and advanced aluminum alloys, will enable the development of lighter and stronger slide-out systems.

- Smart features: Integration of sensors, actuators, and wireless connectivity will enable features like remote operation, load monitoring, and automated locking.

- Modular designs: Modular slide-out systems will allow users to easily customize and reconfigure their truck bed to accommodate different cargo requirements.

- Improved safety features: Development of advanced locking mechanisms, overload protection systems, and anti-pinch sensors will enhance the safety of slide-out systems.

A Forward-Looking Note

The automotive industry is undergoing a rapid transformation, driven by factors such as electrification, autonomous driving, and connectivity. These trends are not only impacting the design and functionality of vehicles but also creating new opportunities for aftermarket accessories like truck bed slide-out systems. As trucks become more integrated with the digital world, expect to see more sophisticated and intelligent slide-out systems that enhance the functionality and versatility of these vehicles. The DIY market will likely benefit from more readily available materials and online resources, making it easier for enthusiasts to create custom solutions tailored to their specific needs. Ultimately, the future of truck bed slide-out systems lies in innovation, customization, and a commitment to safety and reliability, both for commercial and DIY solutions. This will require automotive professionals to stay up-to-date with the latest technologies and best practices to ensure that they can provide their customers with the best possible solutions. The key is to prioritize safety and reliability when designing and building any DIY system.