Engine Oil Pump Replacement

The engine oil pump is the heart of your car's lubrication system. It ensures that critical engine components receive a constant supply of oil, reducing friction, dissipating heat, and preventing premature wear. A failing oil pump can lead to catastrophic engine damage, making its maintenance and timely replacement crucial. This article provides a practical guide for car owners and mechanics on diagnosing, troubleshooting, and replacing engine oil pumps.

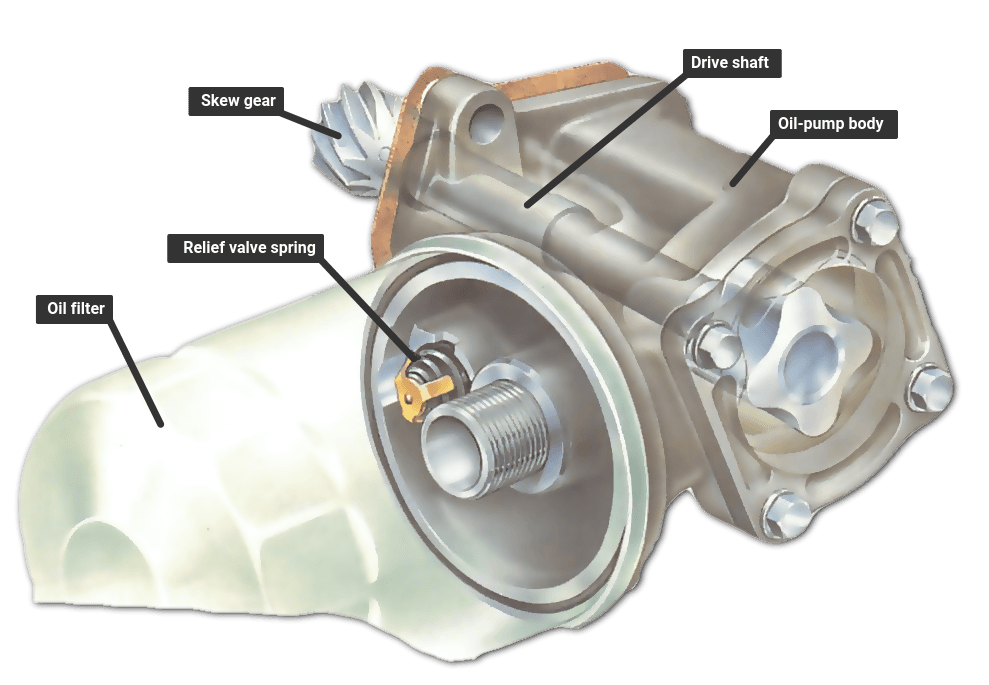

Understanding the Engine Oil Pump

The oil pump is typically a gear-type or rotor-type pump driven by the engine's crankshaft or camshaft. Its primary function is to draw oil from the oil pan and circulate it under pressure throughout the engine. This pressurized oil reaches bearings, pistons, camshafts, and other vital parts, forming a protective film that prevents metal-to-metal contact.

Common Symptoms of a Failing Oil Pump

Recognizing the symptoms of a failing oil pump early can save you from expensive repairs. Here are some common indicators:

- Low Oil Pressure Warning Light: This is the most obvious sign. The oil pressure sensor detects insufficient oil pressure and triggers the warning light on your dashboard. Don't ignore this light! Continuing to drive with low oil pressure can severely damage your engine.

- Engine Noises: A lack of lubrication can cause various engine noises, including rattling, knocking, or ticking sounds, especially at higher RPMs. These sounds indicate that engine parts are rubbing together without adequate oil protection.

- Overheating: Insufficient lubrication leads to increased friction, generating excessive heat. If your engine is overheating more frequently than usual, a failing oil pump could be a contributing factor.

- Poor Engine Performance: Reduced power and sluggish acceleration can also result from inadequate lubrication. The engine has to work harder to overcome the increased friction.

- Hydraulic Lifter Noise: Vehicles with hydraulic lifters may experience excessive lifter noise, particularly at startup. Lifters require adequate oil pressure to function correctly.

Troubleshooting Oil Pump Issues

If you suspect an oil pump problem, a systematic troubleshooting approach is essential. Here's a step-by-step guide:

1. Check Oil Level and Condition

Start with the basics. Ensure the oil level is within the recommended range. Low oil level is the easiest solution to many of these problems. Examine the oil for contamination (e.g., coolant, fuel) or excessive sludge. Dirty or contaminated oil can restrict oil flow and damage the oil pump.

Problem: Low oil level.

Solution: Top off the oil to the correct level, following the manufacturer's recommendations.

Problem: Dirty or sludged oil.

Solution: Perform an oil change using the correct oil type and filter. Consider using an engine flush additive to help remove sludge buildup if the engine has a history of neglected oil changes.

2. Inspect the Oil Pressure Sensor

A faulty oil pressure sensor can provide false readings. Use a scan tool to check the sensor's output. If the reading is inconsistent or doesn't correlate with the actual oil pressure (verified with a mechanical gauge), the sensor may need replacement.

Problem: Faulty oil pressure sensor.

Solution: Replace the oil pressure sensor with a new, quality replacement. Ensure the replacement sensor matches the original specifications.

3. Use a Mechanical Oil Pressure Gauge

Connect a mechanical oil pressure gauge to the engine to verify the actual oil pressure. Compare the readings to the manufacturer's specifications. Low oil pressure readings confirm a potential oil pump issue.

Problem: Low oil pressure confirmed by mechanical gauge.

Solution: Proceed with further investigation of the oil pump, oil pickup tube, and internal engine components.

4. Check the Oil Pickup Tube

The oil pickup tube draws oil from the oil pan. A clogged or damaged pickup tube can restrict oil flow. Remove the oil pan and inspect the pickup tube for debris or damage. Common on cars like older Honda Civics where oil changes aren't done regularly and sludge builds up.

Problem: Clogged oil pickup tube.

Solution: Clean the oil pickup tube thoroughly. If it's severely damaged, replace it.

Problem: Damaged oil pickup tube.

Solution: Replace the oil pickup tube.

5. Inspect the Oil Pump

Visually inspect the oil pump for wear, damage, or excessive play. Check the pump gears or rotors for scoring or breakage. If the pump shows signs of significant wear, replacement is necessary.

Problem: Worn or damaged oil pump.

Solution: Replace the oil pump with a new, quality replacement.

Oil Pump Replacement Procedure

Replacing an oil pump can vary depending on the vehicle model, but here's a general overview of the process:

- Preparation: Disconnect the negative battery terminal. Gather necessary tools, including sockets, wrenches, a torque wrench, and safety glasses. Refer to the vehicle's service manual for specific instructions and torque specifications.

- Draining the Oil: Drain the engine oil completely. Remove the oil filter.

- Removing the Oil Pan: Remove the oil pan. This may require disconnecting exhaust components or other parts that obstruct access.

- Accessing the Oil Pump: The oil pump is typically located inside the oil pan, often driven by the crankshaft. Disconnect any electrical connectors or lines attached to the pump.

- Removing the Old Oil Pump: Unbolt the oil pump from the engine block. Note the orientation of the pump and any shims or spacers.

- Installing the New Oil Pump: Install the new oil pump, ensuring it's properly aligned. Use new gaskets or O-rings as needed. Torque the bolts to the manufacturer's specifications.

- Reassembling: Reinstall the oil pickup tube, oil pan, and oil filter. Use new gaskets for the oil pan to prevent leaks.

- Refilling: Refill the engine with the correct type and amount of oil.

- Priming the Oil System: Prime the oil system by cranking the engine for a few seconds without starting it. This allows the new oil pump to draw oil and circulate it through the engine. Some vehicles may have a specific priming procedure outlined in the service manual.

- Starting the Engine: Start the engine and monitor the oil pressure gauge or warning light. Ensure the oil pressure reaches the normal operating range.

- Checking for Leaks: Inspect for any oil leaks around the oil pan, oil filter, and oil pump area.

Example: On a Ford F-150 with a 5.4L engine, oil pump failure can be related to timing chain issues. Metal debris from worn timing chain guides can contaminate the oil and damage the oil pump. In this case, replacing both the timing chains and the oil pump simultaneously is often recommended.

Real-World Issues and Considerations

- Aftermarket vs. OEM Oil Pumps: While aftermarket oil pumps can be more affordable, consider the quality and reliability. OEM (Original Equipment Manufacturer) pumps are generally more reliable and come with a warranty.

- Oil Pump Gaskets and Seals: Always use new gaskets and seals when replacing an oil pump. Old gaskets can leak, leading to oil pressure loss.

- Torque Specifications: Adhere to the manufacturer's torque specifications when tightening bolts. Overtightening can damage the pump or the engine block. Undertightening can cause leaks.

- Engine Sludge: If the engine has a history of neglect and sludge buildup, cleaning the oil pan and oil passages is crucial before installing a new oil pump. Otherwise, the new pump may quickly become clogged.

- Professional Assistance: If you're not comfortable performing the oil pump replacement yourself, consult a qualified mechanic. Improper installation can lead to serious engine damage. For example, some Subaru models require precise alignment during oil pump installation to ensure proper oil flow to the horizontally opposed cylinders.

Preventative Maintenance for a Healthy Oil Pump

Preventative maintenance is key to extending the life of your engine oil pump and avoiding costly repairs:

- Regular Oil Changes: Adhere to the manufacturer's recommended oil change intervals. Use the correct type and viscosity of oil. Regular oil changes remove contaminants and sludge that can damage the oil pump.

- Use Quality Oil Filters: A good quality oil filter removes dirt and debris from the oil, protecting the oil pump and other engine components.

- Avoid Extended Idling: Prolonged idling can increase engine wear and contribute to oil sludge buildup.

- Address Oil Leaks Promptly: Repair any oil leaks immediately to maintain adequate oil levels and prevent oil pump starvation.

- Listen to Your Engine: Pay attention to any unusual engine noises, such as knocking or rattling. These sounds can be early warning signs of oil pump problems.

Conclusion

The engine oil pump is a critical component for engine longevity. By understanding the symptoms of a failing oil pump, following a systematic troubleshooting approach, and performing regular maintenance, you can keep your car's engine properly lubricated and running smoothly for years to come. Remember, when in doubt, consult a qualified mechanic to ensure the job is done correctly. Taking care of your oil pump is an investment in the long-term health and reliability of your vehicle. Neglecting it can result in costly repairs and potentially catastrophic engine failure. Don't wait for the warning light to come on; be proactive about your engine's lubrication system! Regular oil checks and preventative maintenance are your best defenses against oil pump problems.

A little bit of prevention is worth a pound of cure.By following these guidelines, you can ensure your car's engine stays in top condition.