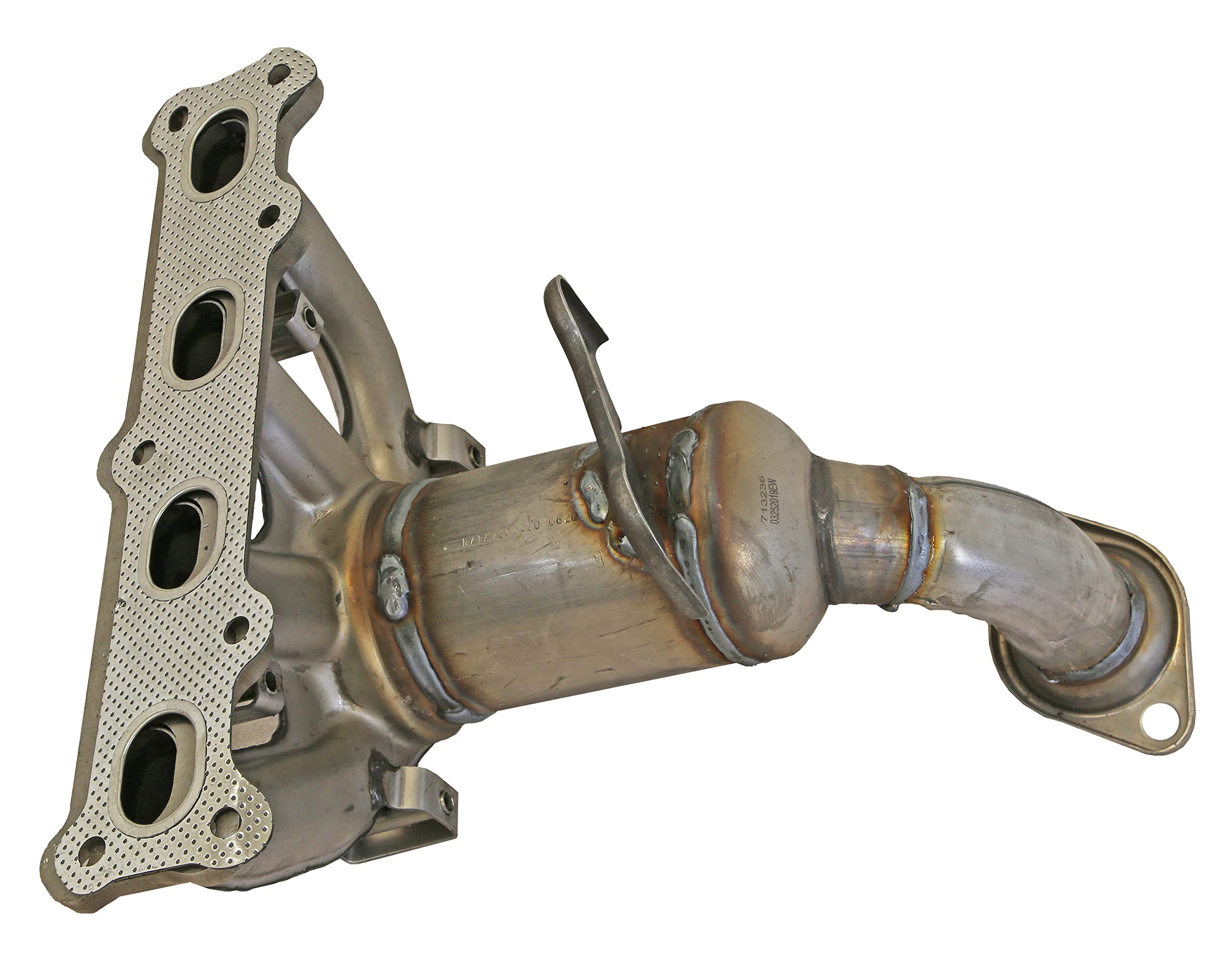

Exhaust Manifold To Catalytic Converter

The connection between the exhaust manifold and the catalytic converter is a crucial, yet often overlooked, part of an engine's exhaust system. It's more than just a pipe; it's an engineered interface that dictates performance, emissions, and longevity. This article delves into the intricacies of this vital connection, exploring its technical specifications, engineering choices, performance impacts, alternatives, and future trends.

Technical Specifications and Engineering Considerations

The primary function of this connection is to channel hot exhaust gases from the exhaust manifold to the catalytic converter with minimal energy loss and efficient flow. Several technical specifications govern its design:

- Material Selection: Typically, this section is constructed from stainless steel or aluminized steel. Stainless steel provides superior corrosion resistance, especially in harsh environments with road salt. Aluminized steel is a more cost-effective option offering decent corrosion protection. The choice often depends on the vehicle's target market and price point.

- Pipe Diameter: The diameter is carefully calculated to optimize exhaust gas velocity. Too small, and backpressure increases, hurting engine performance. Too large, and the exhaust gas velocity drops, reducing the effectiveness of the catalytic converter and potentially leading to increased emissions.

- Wall Thickness: Wall thickness is determined by the thermal and mechanical stresses the pipe must withstand. Thicker walls offer better durability but increase weight and cost.

- Flexibility: A flexible section is often incorporated to absorb engine vibrations and thermal expansion, preventing stress on the exhaust manifold and catalytic converter. This flex section is usually a braided stainless steel bellows.

- Flange Design: The flanges at each end, connecting to the exhaust manifold and catalytic converter, are critical for a gas-tight seal. They must be robust and resistant to warping under high temperatures. Gaskets are also crucial, with multi-layer steel (MLS) gaskets being a common choice for their superior sealing capabilities and resistance to blowout.

- Heat Shielding: Heat shields are frequently employed to reduce radiant heat transfer to surrounding components, protecting wiring harnesses, fuel lines, and other heat-sensitive parts.

Engineering choices heavily influence performance. For example, some manufacturers use mandrel bending to ensure a consistent pipe diameter throughout the bends, minimizing flow restriction. Others may opt for crush bending, which is less expensive but can reduce flow efficiency.

Real-World Performance and Alternatives

The performance of the exhaust manifold-to-catalytic converter connection directly impacts several key areas:

- Engine Power and Torque: A restrictive connection increases backpressure, reducing engine power and torque, particularly at higher RPMs.

- Fuel Efficiency: Increased backpressure forces the engine to work harder, leading to reduced fuel efficiency.

- Emissions: An inefficient connection can negatively impact the performance of the catalytic converter, increasing emissions of harmful pollutants such as hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx).

- Sound: The design can influence exhaust sound, with some aftermarket options tuned to produce a more aggressive tone.

Alternatives to a traditional pipe connection include:

- Integrated Manifold/Converter: Some vehicles, particularly those with space constraints, integrate the exhaust manifold and catalytic converter into a single unit. This reduces the number of connections and can improve thermal efficiency but makes individual component replacement more difficult and expensive.

- Cast Manifold/Converter: Using a casting to integrate both components can improve flow dynamics and thermal management, but increases weight and complexity.

Pros and Cons: Comparison

Traditional Pipe Connection:

- Pros: Relatively inexpensive, easier to replace individual components, flexible design.

- Cons: More connections increase the risk of leaks, potential for higher backpressure compared to integrated designs, more susceptible to corrosion at joints.

Integrated Manifold/Converter:

- Pros: Reduced connections and potential leak points, improved thermal efficiency in some designs, potentially lower backpressure.

- Cons: More expensive to replace (the entire unit needs replacement if either component fails), less flexible design, can be more challenging to install/remove.

Reliability Aspects and Maintenance Tips

The exhaust manifold-to-catalytic converter connection is subjected to harsh conditions, including high temperatures, vibrations, and corrosive exhaust gases. This can lead to several reliability issues:

- Corrosion: Road salt and moisture can accelerate corrosion, particularly on aluminized steel components.

- Leakage: Gaskets can degrade over time, leading to exhaust leaks. Loose bolts or warped flanges can also cause leaks.

- Cracking: Thermal stress and vibration can cause cracks to form, especially in the flex section or at weld points.

- Catalytic Converter Damage: Leaks upstream of the catalytic converter can negatively impact its performance and lifespan.

Maintenance tips to ensure reliability:

- Regular Inspections: Visually inspect the connection for signs of corrosion, leaks, or damage during routine maintenance.

- Torque Checks: Periodically check the torque of the flange bolts to ensure a proper seal.

- Gasket Replacement: Replace gaskets whenever the connection is disassembled or if there are signs of leakage. Use high-quality MLS gaskets for optimal sealing.

- Anti-Seize Compound: Apply anti-seize compound to the flange bolts to prevent them from seizing due to corrosion.

- Proper Installation: Follow the manufacturer's instructions carefully during installation to avoid over-tightening bolts or damaging the flanges.

Future Trends

Several trends are shaping the future of exhaust systems, including the connection between the exhaust manifold and catalytic converter:

- Advanced Materials: The use of lightweight and high-temperature resistant materials, such as titanium alloys and advanced composites, is being explored to reduce weight and improve thermal efficiency.

- Improved Catalytic Converter Technology: As emission standards become stricter, catalytic converters are becoming more efficient and complex. This requires more precise control of exhaust gas flow and temperature, influencing the design of the connecting pipe.

- Electric Vehicles (EVs) and Hybridization: The increasing popularity of EVs and hybrid vehicles is significantly impacting the exhaust system market. While EVs eliminate the need for an exhaust system altogether, hybrid vehicles still require efficient and lightweight exhaust systems.

- Active Exhaust Systems: These systems use valves to control exhaust flow and sound, allowing for adjustable performance and noise levels. The connection to the catalytic converter must be designed to accommodate these valves and their associated actuators.

- Computational Fluid Dynamics (CFD) Optimization: CFD simulations are increasingly used to optimize the design of exhaust systems, ensuring optimal flow characteristics and minimizing backpressure.

As engines shrink in size and become more sophisticated, the manifold-to-converter connection is becoming increasingly critical to overall system performance. The trend of minimizing weight and maximizing efficiency drives innovation in materials and designs. Moreover, onboard diagnostic (OBD) systems are becoming more adept at monitoring exhaust system performance, helping to quickly identify any faults or degradation that could impact emissions.

Conclusion

The exhaust manifold-to-catalytic converter connection, while seemingly simple, is a complex and vital component of the modern automotive exhaust system. Understanding its technical specifications, engineering choices, and performance impacts is crucial for automotive professionals. As the automotive industry continues to evolve, with a focus on fuel efficiency, emissions reduction, and electrification, this connection will undoubtedly undergo further innovation and refinement, playing a key role in meeting future environmental regulations and performance demands. The integration of advanced materials, intelligent systems, and sophisticated control strategies will continue to shape its future, solidifying its role as a crucial link in the powertrain ecosystem. Adapting to these changes is critical for automotive technicians and engineers alike.