Gas Tank Filler Neck Problems

Alright, let's dive into a common, yet often overlooked, area of automotive maintenance and repair: the gas tank filler neck. While it seems like a simple component, problems with your filler neck can lead to fuel leaks, difficulty filling up, and even emissions test failures. This article will cover common problems, their causes, diagnosis, and repair solutions for the experienced DIYer.

Understanding the Anatomy of a Filler Neck

Before we start troubleshooting, it's essential to understand the basic components. The filler neck is the pipe that connects the fuel tank to the gas cap opening on the exterior of your vehicle. It allows you to safely and efficiently refuel your car. It's usually made of metal (steel or aluminum) or, increasingly, durable plastic composites. Key components include:

- Filler Neck Pipe: The main conduit for fuel. Its diameter and shape are crucial for proper fuel flow.

- Vent Pipe(s): Often smaller pipes running parallel to the main pipe. These are critical for venting air from the tank as it fills, preventing backpressure and allowing for a smoother fill. They're integral to the EVAP (Evaporative Emission Control) system.

- Fuel Cap Connection: The threaded or bayonet-style receiver for your gas cap. This needs to seal tightly to prevent fuel vapor leaks.

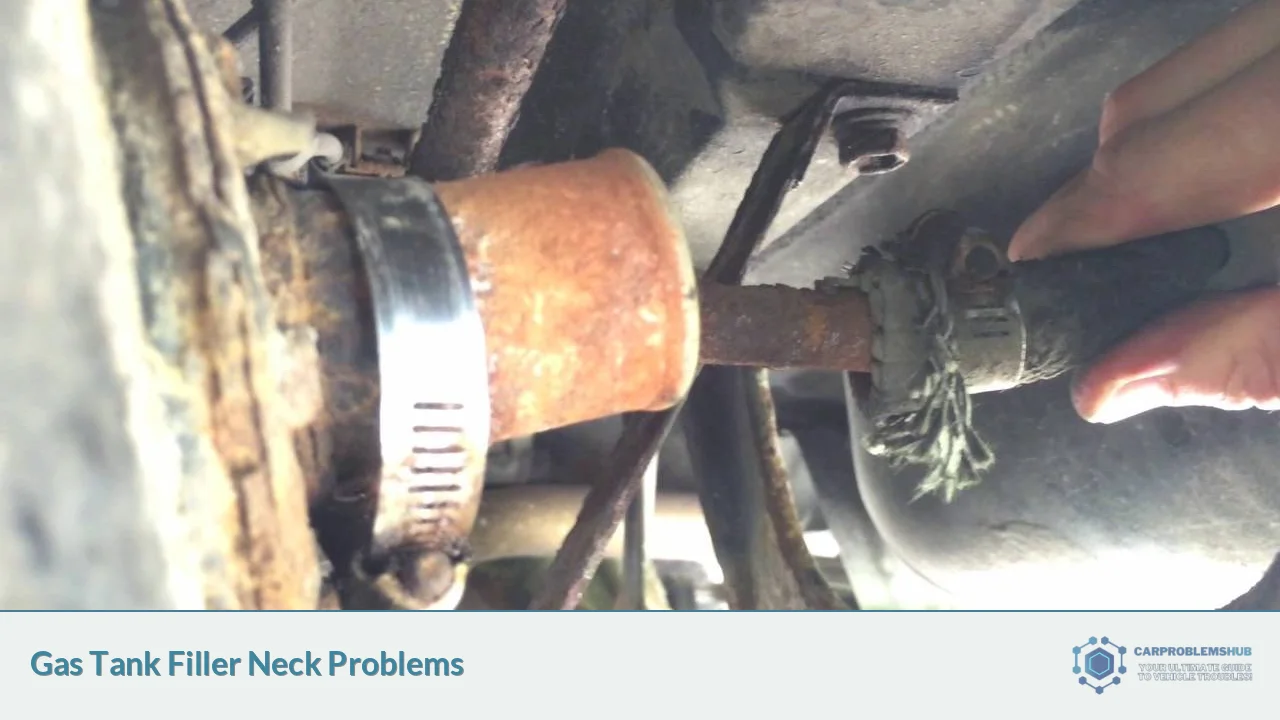

- Fuel Tank Connection: The point where the filler neck attaches to the fuel tank, usually with a rubber hose and clamps, or sometimes welded directly to the tank.

- Drainage System: Often a small channel or tube to route spilled fuel away from sensitive areas and towards the ground.

Common Filler Neck Problems

Now, let's explore the common issues you might encounter:

Rust and Corrosion

This is the most prevalent problem, especially in older vehicles or those operating in regions with harsh winters and road salt. Steel filler necks are susceptible to rust, particularly at seams, welds, and areas exposed to the elements. Corrosion can lead to:

- Fuel Leaks: Small pinholes in the metal can develop due to rust, causing fuel to leak out, especially when the tank is full. The smell of gasoline is a telltale sign.

- Weakened Structure: Extensive rust weakens the neck, making it susceptible to damage from impacts or stress.

- EVAP System Failures: Rust can compromise the vent pipes, leading to leaks in the EVAP system and triggering a "Check Engine" light with codes like P0440, P0442, or P0455, indicating a small or large EVAP leak.

Damage from Impacts

Even minor fender benders or accidents can damage the filler neck, even if the external damage seems minimal. Impacts can:

- Dent the Neck: A dent can restrict fuel flow and make filling up difficult.

- Crack the Neck: Especially in plastic filler necks, impacts can cause cracks that lead to fuel leaks or EVAP system failures.

- Damage the Fuel Cap Connection: A damaged connection can prevent the fuel cap from sealing properly, leading to fuel vapor leaks.

Deteriorated Rubber Hoses and Clamps

The rubber hose connecting the filler neck to the fuel tank can deteriorate over time due to exposure to fuel, heat, and ozone. Clamps can also rust or loosen. This can cause:

- Fuel Leaks: Leaks are most likely to occur at the hose connections.

- EVAP System Leaks: Cracks in the hose can introduce leaks into the EVAP system.

Blocked Vent Pipes

Debris, rust, or even insect nests can block the vent pipes, leading to:

- Slow Fueling: Fuel may splash back out of the filler neck while fueling because the air in the tank cannot escape quickly enough.

- Fuel Shut-Off Issues: The fuel pump at the gas station may repeatedly shut off, even though the tank isn't full.

Fuel Cap Issues

While not technically part of the filler neck itself, a faulty fuel cap can mimic filler neck problems. A worn or damaged fuel cap can:

- Cause EVAP System Leaks: A loose or cracked cap won't seal properly, triggering EVAP system codes.

Diagnosis and Troubleshooting

Identifying the root cause of your filler neck problem is crucial before attempting any repairs. Here's a step-by-step approach:

- Visual Inspection: Start with a thorough visual inspection. Look for signs of rust, corrosion, cracks, dents, and leaks. Pay close attention to the seams, welds, hose connections, and fuel cap connection. Use a flashlight to inspect hard-to-reach areas.

- Smell Test: A strong gasoline odor, especially near the fuel filler area, is a clear indication of a leak. Try to pinpoint the source of the smell.

- EVAP System Testing: If you have a "Check Engine" light with EVAP codes, use an OBD-II scanner to read the codes. Then, perform a smoke test. This involves injecting smoke into the EVAP system and looking for leaks. Leaks often manifest around the filler neck. A smoke machine is a valuable tool for this purpose.

- Pressure Testing: Some shops use pressure testing to check the fuel tank and filler neck for leaks. This involves pressurizing the system and monitoring for pressure drops.

- Fuel Cap Inspection: Inspect the fuel cap for cracks, damage to the rubber seal, and proper tightness. A simple test is to try tightening the cap until it clicks. If it doesn't click or feels loose, the cap is likely faulty. You can also try a new, known-good fuel cap to see if the problem resolves.

- Hose and Clamp Inspection: Carefully inspect the rubber hose connecting the filler neck to the fuel tank. Look for cracks, swelling, or signs of deterioration. Check the clamps for rust and tightness.

Repair and Replacement Options

Once you've identified the problem, you have several options, depending on the severity and nature of the damage:

Minor Rust Repair

If the rust is superficial and hasn't compromised the structural integrity of the filler neck, you can try to repair it. This involves:

- Cleaning: Thoroughly clean the affected area with a wire brush and sandpaper to remove all rust and loose paint.

- Rust Converter: Apply a rust converter to neutralize any remaining rust.

- Primer: Apply a rust-inhibiting primer.

- Paint: Apply a durable topcoat of paint designed for automotive use.

Important: This is only a temporary fix for surface rust. If the rust is deep or has created holes, the filler neck needs to be replaced.

Hose and Clamp Replacement

Replacing deteriorated rubber hoses and clamps is a straightforward repair. Use fuel-resistant hose that meets or exceeds OEM specifications. Ensure the clamps are properly sized and tightened to prevent leaks.

Filler Neck Replacement

If the filler neck is severely rusted, damaged, or cracked, replacement is the best option. This is a more involved repair, but it's essential for safety and proper operation. Here's a general outline:

- Safety First: Disconnect the negative battery cable. Depressurize the fuel system. Work in a well-ventilated area and have a fire extinguisher nearby.

- Drain Fuel: If possible, drain as much fuel as possible from the tank to reduce the risk of spills and fire.

- Disconnect Hoses and Clamps: Carefully disconnect the rubber hoses and clamps connecting the filler neck to the fuel tank. Be prepared for some fuel spillage.

- Remove Mounting Hardware: Remove any bolts, screws, or straps that secure the filler neck to the vehicle.

- Remove the Old Filler Neck: Carefully maneuver the old filler neck out of the vehicle.

- Install the New Filler Neck: Install the new filler neck in the reverse order of removal. Ensure all hoses are properly connected and clamps are tightened.

- Refill and Test: Add a small amount of fuel to the tank and check for leaks. Start the engine and monitor for leaks. Clear any EVAP system codes.

Note: Some vehicles may require removing the fuel tank to access the filler neck. Refer to your vehicle's repair manual for specific instructions.

Fuel Cap Replacement

A new fuel cap is an inexpensive and easy way to address potential EVAP system leaks. Choose a cap that is specifically designed for your vehicle's make and model.

Preventive Maintenance

Preventing filler neck problems is always better than dealing with repairs. Here are a few tips:

- Regular Inspection: Inspect the filler neck and surrounding area regularly for signs of rust, corrosion, or damage.

- Undercoating: Apply undercoating to protect the filler neck from rust and corrosion, especially in areas prone to road salt.

- Prompt Repairs: Address any minor rust or damage promptly to prevent it from worsening.

- Fuel Additives: Use fuel additives that contain corrosion inhibitors to help protect the fuel system.

By understanding the anatomy, common problems, diagnosis, and repair options for gas tank filler necks, you can confidently tackle this often-overlooked area of automotive maintenance and keep your vehicle running smoothly and safely. Remember to always prioritize safety and consult your vehicle's repair manual for specific instructions and torque specifications.