Head Bolt Torque Nissan Torque Specs

The cylinder head is a critical component in any internal combustion engine, responsible for sealing the combustion chamber and housing vital components like valves and camshafts. Ensuring a proper seal and preventing catastrophic engine failure hinges significantly on the correct installation and, most importantly, the precise torque application to the head bolts. This article provides an in-depth look at head bolt torque specifications for Nissan engines, focusing on the engineering choices behind them, real-world performance, and comparing them to alternative fastening strategies.

Understanding Nissan Head Bolt Torque Specifications

Nissan, like other automotive manufacturers, employs specific torque specifications for its head bolts, meticulously determined through extensive engineering and testing. These specifications are not arbitrary; they are calculated to achieve the optimal clamping force between the cylinder head and the engine block. This clamping force must be sufficient to withstand the immense pressures generated during combustion, prevent coolant and oil leaks, and maintain the integrity of the cylinder head gasket. Nissan often uses a combination of torque-to-yield (TTY) and torque-angle specifications. TTY bolts are designed to stretch elastically beyond their yield point when tightened, providing a more consistent and reliable clamping force. This approach allows for tighter tolerances and better sealing compared to traditional torque-only methods.

Common Nissan Torque Specifications: A Closer Look

Torque specifications vary considerably between different Nissan engine families and even within different variations of the same engine. Factors like engine displacement, materials used in the block and head, and the type of cylinder head gasket all influence the specified torque values and tightening sequence. Here are a few examples to illustrate the variation:

- VQ35DE (3.5L V6): Commonly found in vehicles like the 350Z and Altima, this engine often utilizes a TTY bolt system with a preliminary torque value followed by an angle turn (e.g., 22 lb-ft + 90 degrees).

- QR25DE (2.5L Inline-4): Used in various models including the Altima and Sentra, the QR25DE also often uses TTY bolts with a specific torque sequence and angle tightening.

- KA24DE (2.4L Inline-4): A slightly older engine found in models like the 240SX and pickup trucks, may use more traditional torque specifications without the angle tightening.

It is absolutely critical to consult the correct service manual for the specific engine and model year to obtain the accurate torque specifications and tightening sequence. Using incorrect values can lead to severe engine damage, including blown head gaskets, warped cylinder heads, and even cracked engine blocks.

Engineering Choices and Rationale

Nissan's choice to use TTY bolts stems from the desire for greater precision and consistency in clamping force. Traditional torque-only methods are subject to variations due to friction, thread condition, and lubrication. TTY bolts, by stretching beyond their yield point, minimize these variables and provide a more uniform clamping load across all bolts. The angle tightening step further refines the process, ensuring that each bolt is stretched to the precise length required.

The specific torque values and angle turns are determined through extensive finite element analysis (FEA) and physical testing. Engineers carefully model the cylinder head and block, simulating the forces and stresses that occur during combustion. This analysis allows them to optimize the bolt size, material, and tightening specifications to achieve the desired clamping force while minimizing the risk of bolt failure or component damage.

Comparison with Alternatives

While TTY bolts are widely used, alternative fastening strategies exist, each with its own pros and cons:

- Traditional Torque-Only Bolts: These bolts are tightened to a specific torque value and do not rely on stretching beyond the yield point.

Pros: Reusable in some cases, simpler installation. Cons: Less consistent clamping force, more susceptible to variations due to friction.

- Studs and Nuts: Replacing head bolts with studs and nuts can offer increased clamping force and improved thread engagement.

Pros: Superior clamping force, more consistent clamping, reduced risk of thread damage in the block. Cons: More expensive, more complex installation, potential clearance issues.

- Aftermarket High-Performance Bolts/Studs: Companies like ARP offer specialized head bolts and studs made from high-strength materials.

Pros: Highest clamping force, improved durability, designed for high-performance applications. Cons: Most expensive, often require block modification.

For most stock Nissan engine rebuilds, using OEM TTY bolts and adhering to the specified torque and angle values is sufficient. However, for high-performance applications or engines experiencing repeated head gasket failures, upgrading to studs and nuts may be a worthwhile investment.

Real-World Performance and Reliability

When properly installed and torqued, Nissan head bolts provide excellent sealing and reliability. However, several factors can compromise their performance:

- Over-Torquing: Exceeding the specified torque can damage the bolts or the threads in the block, leading to premature failure.

- Under-Torquing: Insufficient torque will not provide adequate clamping force, resulting in head gasket leaks and potential engine damage.

- Thread Damage: Damaged threads in the block can prevent proper clamping and lead to bolt failure.

- Incorrect Lubrication: Using the wrong type of lubricant or applying it improperly can affect the torque readings and clamping force. Always use the lubricant specified in the service manual.

- Reusing TTY Bolts: TTY bolts are designed for single use only. Reusing them can compromise their strength and lead to failure.

Regular maintenance, including proper cooling system maintenance and avoiding engine overheating, is crucial for preserving the integrity of the head gasket and head bolts. Overheating can weaken the bolts and cause the cylinder head to warp, leading to leaks and potential engine damage.

Maintenance Tips and Best Practices

To ensure proper head bolt installation and prevent future problems, follow these best practices:

- Consult the Service Manual: Always refer to the correct service manual for the specific engine and model year to obtain the accurate torque specifications, tightening sequence, and lubrication recommendations.

- Use a Torque Wrench: Use a high-quality torque wrench that is properly calibrated.

- Clean Threads: Thoroughly clean the threads in the block and on the bolts.

- Lubricate Properly: Apply the specified lubricant to the threads and under the bolt heads.

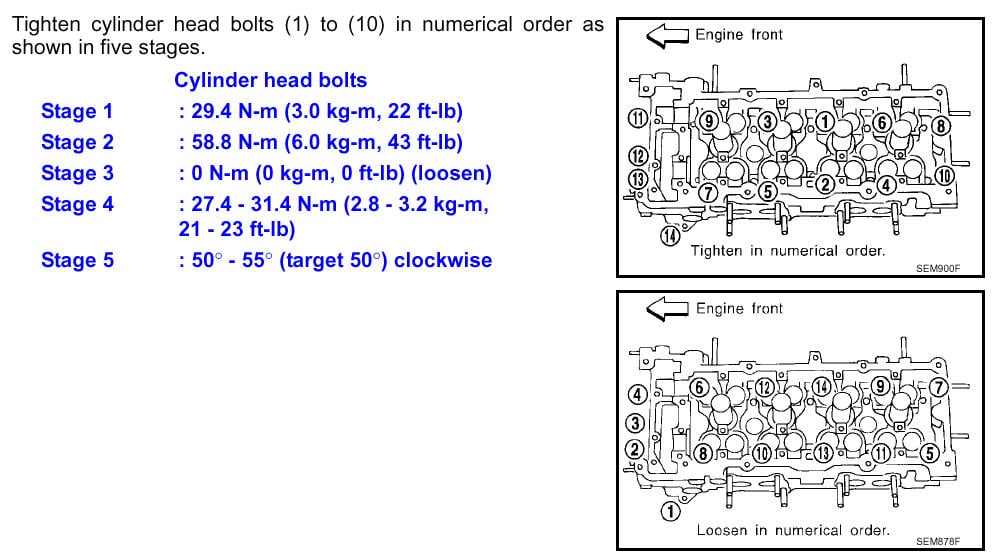

- Follow the Tightening Sequence: Adhere to the specified tightening sequence to ensure even clamping force across the cylinder head.

- Use New Bolts: Always use new TTY bolts.

- Angle Tightening: Use an accurate angle meter or torque angle gauge for angle tightening.

- Inspect the Cylinder Head and Block: Inspect the cylinder head and block for any signs of warping, cracks, or damage before installation.

Future Trends in Automotive Fastening

The automotive industry is constantly evolving, and advancements in engine technology are driving changes in fastening strategies. Some future trends include:

- Lightweight Materials: The increasing use of aluminum and composite materials in engine construction requires more sophisticated fastening solutions.

- Higher Cylinder Pressures: Modern engines are designed to operate at higher cylinder pressures, demanding stronger and more reliable head bolts.

- Advanced Torque Control: Electronic torque control systems are becoming more prevalent, allowing for precise monitoring and adjustment of clamping force.

- Self-Locking Fasteners: The development of self-locking fasteners that do not require external locking devices is gaining momentum.

Conclusion

Understanding and adhering to the correct head bolt torque specifications is paramount for ensuring the reliability and longevity of Nissan engines. By appreciating the engineering principles behind TTY bolts and following best practices for installation, automotive professionals can minimize the risk of engine failure and provide their customers with dependable service. The automotive industry's ongoing pursuit of improved engine performance and fuel efficiency will continue to drive innovation in fastening technology, requiring technicians to stay informed and adapt to new techniques and materials. The future of engine building will depend on understanding the nuances of these advanced technologies and applying them with precision and care.