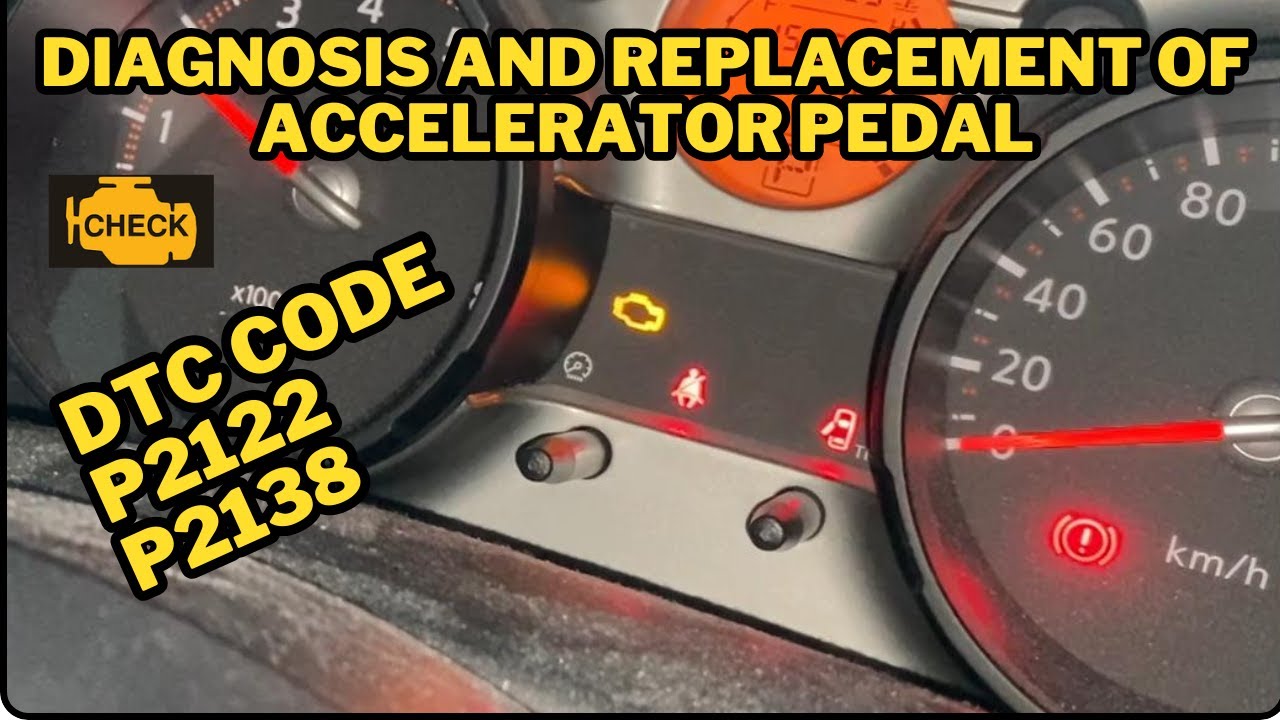

How Do I Fix Error Code P2138

The diagnostic trouble code (DTC) P2138, "Throttle/Pedal Position Sensor/Switch 'D'/'E' Voltage Correlation," is a common thorn in the side of many modern vehicles. It indicates a discrepancy between the readings of the two throttle position sensors (TPS) or accelerator pedal position sensors (APPS). Because modern engine control systems rely heavily on accurate throttle input, resolving a P2138 promptly is crucial for maintaining drivability and preventing potential engine damage. This article provides a comprehensive guide to diagnosing and repairing error code P2138, catering to enthusiasts, DIY mechanics, and seasoned professionals alike.

Understanding the P2138 Code

Before diving into diagnostics, let's clarify what the P2138 code signifies. Most vehicles employ two or more throttle position sensors (TPS) or accelerator pedal position sensors (APPS) for redundancy and to improve accuracy. These sensors are potentiometers, meaning they provide a variable voltage signal to the engine control module (ECM) that corresponds to the throttle or pedal position. The ECM continuously monitors these signals and expects them to correlate within a specified range. When the ECM detects a significant deviation between the sensor signals, it triggers the P2138 code.

This discrepancy can lead to various drivability issues, including reduced engine power, hesitation during acceleration, erratic shifting in automatic transmissions, and even limp-home mode activation. Limp-home mode is a safety feature designed to protect the engine and transmission by severely limiting engine output.

Common Causes of P2138

Several factors can trigger a P2138 code. Identifying the root cause is paramount for an effective repair. Here are some of the most common culprits:

- Faulty Throttle Position Sensor (TPS) or Accelerator Pedal Position Sensor (APPS): These sensors can degrade over time, leading to inaccurate readings. This is the most frequent cause.

- Wiring Issues: Damaged, corroded, or shorted wiring in the sensor circuits can disrupt the signal transmission to the ECM. This includes the signal wires, the 5-volt reference wire, and the ground wire.

- Connector Problems: Loose or corroded connectors at the TPS/APPS or the ECM can cause signal interruptions.

- ECM Malfunction: Although less common, a faulty ECM can misinterpret sensor signals or generate erroneous fault codes.

- Throttle Body Issues: In some cases, a dirty or sticking throttle body can interfere with the TPS operation, leading to a P2138 code. Carbon buildup can prevent the throttle plate from moving freely.

- Pedal Assembly Problems: Issues within the accelerator pedal assembly itself, such as a worn pedal pivot or internal damage, can contribute to the code.

Diagnostic Procedure

A systematic approach is crucial for accurately diagnosing a P2138 code. Follow these steps to pinpoint the problem:

1. Preliminary Inspection and Code Verification

Begin by connecting a scan tool to the vehicle's OBD-II port and verifying the presence of the P2138 code. Record any other related DTCs, as they can provide valuable clues. Clear the codes and perform a test drive to see if the P2138 code returns. This helps confirm whether the problem is intermittent or persistent.

2. Visual Inspection

Thoroughly inspect the wiring and connectors associated with the TPS and APPS. Look for any signs of damage, corrosion, or loose connections. Pay close attention to areas where the wiring harness may rub against other components. Ensure the throttle body is clean and the throttle plate moves freely without sticking. Check the accelerator pedal assembly for any signs of damage or binding.

3. Sensor Testing

This is where a multimeter becomes your best friend. You will be testing both the TPS and the APPS.

TPS Testing: Refer to the vehicle's service manual for the specific voltage range of the TPS. With the ignition on but the engine off, back-probe the TPS signal wires with a multimeter. Slowly open and close the throttle and observe the voltage readings. The voltage should increase smoothly and linearly as the throttle opens, without any abrupt jumps or dead spots. If the voltage readings are erratic or outside the specified range, the TPS is likely faulty.

APPS Testing: The APPS operates similarly to the TPS. Consult the service manual for the correct voltage range. With the ignition on, back-probe the APPS signal wires and slowly depress and release the accelerator pedal. Monitor the voltage readings for smooth, linear changes. Any erratic readings or deviations from the specified range indicate a faulty APPS.

Important Note: Some vehicles require specialized scan tools to properly diagnose the TPS and APPS. These tools can display the sensor readings in real-time and allow for more comprehensive testing.

4. Wiring Circuit Testing

If the sensors appear to be functioning correctly, the next step is to test the wiring circuits. Use a multimeter to check for the following:

- Continuity: Verify the continuity of each wire in the TPS/APPS circuit, from the sensor connector to the ECM connector.

- Voltage: Check the 5-volt reference voltage at the TPS/APPS connector.

- Ground: Ensure a good ground connection at the TPS/APPS connector.

- Short to Ground/Voltage: Check for shorts to ground or voltage in the signal wires.

Any open circuits, shorts, or excessive resistance in the wiring indicate a wiring problem that needs to be addressed.

5. ECM Diagnosis

If all other components and wiring check out okay, the ECM may be the culprit. However, before condemning the ECM, double-check all previous steps to rule out any other possibilities. ECM diagnosis often requires specialized tools and expertise, so it's best left to a qualified technician.

Repair Procedures

Once you've identified the cause of the P2138 code, you can proceed with the appropriate repair.

Replacing a Faulty TPS/APPS

Replacing a faulty TPS or APPS is a relatively straightforward procedure. Disconnect the negative battery cable, locate the sensor, disconnect the electrical connector, and remove the mounting screws. Install the new sensor, ensuring it's properly aligned, and tighten the mounting screws to the specified torque. Reconnect the electrical connector and the negative battery cable. Clear the DTCs and perform a test drive to verify the repair.

Repairing Wiring and Connectors

Repairing wiring involves splicing or replacing damaged wires. Use high-quality connectors and ensure proper crimping. Protect the repaired wiring with heat shrink tubing or electrical tape. Clean corroded connectors with electrical contact cleaner and apply dielectric grease to prevent future corrosion.

Cleaning the Throttle Body

If the throttle body is dirty, clean it with a throttle body cleaner. Remove the air intake duct and spray the cleaner onto the throttle plate and surrounding area. Use a soft cloth or brush to remove carbon buildup. Be careful not to damage the throttle plate or the throttle body bore.

ECM Repair/Replacement

ECM repair or replacement is a complex procedure that typically requires reprogramming. It's best left to a qualified technician with the necessary tools and expertise. After replacing the ECM, it needs to be programmed to the vehicle using a scan tool. This typically involves entering the vehicle's VIN and other relevant information.

Preventative Measures

While some failures are unavoidable, the following measures can help prevent P2138 and other related issues:

- Regular Vehicle Maintenance: Adhere to the manufacturer's recommended maintenance schedule, including throttle body cleaning and inspection of wiring and connectors.

- Protect Wiring: Ensure wiring harnesses are properly secured and protected from chafing.

- Use Quality Parts: When replacing sensors or other components, use high-quality parts from reputable manufacturers.

- Address Issues Promptly: Don't ignore warning signs such as drivability issues or illuminated check engine lights. Address these issues promptly to prevent further damage.

Real-World Examples

Example 1: A 2012 Honda Civic experienced intermittent hesitation during acceleration and a recurring P2138 code. After a thorough inspection, the technician found a corroded connector at the APPS. Cleaning the connector and applying dielectric grease resolved the issue.

Example 2: A 2015 Ford F-150 displayed a P2138 code and went into limp-home mode. Testing revealed that one of the TPS sensors was producing erratic voltage readings. Replacing the faulty TPS sensor fixed the problem.

Example 3: A 2018 Chevrolet Silverado exhibited a P2138 code and poor fuel economy. The throttle body was found to be heavily carbonized, restricting airflow. Cleaning the throttle body improved drivability and fuel economy, and the P2138 code disappeared.

Conclusion

The P2138 code can be a frustrating issue, but with a systematic diagnostic approach and a thorough understanding of the system, it can be effectively resolved. By following the steps outlined in this guide, you can diagnose and repair the P2138 code and restore your vehicle's performance. Remember to always consult the vehicle's service manual for specific procedures and specifications. Whether you're an automotive enthusiast, a DIY mechanic, or a seasoned professional, a solid understanding of the P2138 code will prove invaluable in maintaining and repairing modern vehicles.