How Do You Fix A Cracked Dashboard

The bane of many automotive interiors, a cracked dashboard is not only an aesthetic eyesore but can also impact resale value and even safety. For automotive professionals, understanding the causes, repair options, and preventative measures for dashboard cracks is crucial. This article delves into the complexities of dashboard crack repair, examining the technical specifications, engineering choices, real-world performance, and future trends.

Understanding the Root Cause of Dashboard Cracks

Before attempting any repair, it's vital to understand why dashboards crack in the first place. Several factors contribute, with the primary culprit being prolonged exposure to ultraviolet (UV) radiation from the sun.

Dashboards are typically constructed from a combination of materials, often including:

- Polyvinyl Chloride (PVC): A common plastic known for its durability and cost-effectiveness. However, it's susceptible to UV degradation, leading to embrittlement and cracking.

- Acrylonitrile Butadiene Styrene (ABS): Offers better impact resistance than PVC but is also affected by UV exposure.

- Polyurethane (PU) Foam: Used for padding and impact absorption. Its breakdown contributes to surface imperfections that can exacerbate cracking.

- Vinyl or Leather Covering: Provides the aesthetic finish but can dry out and crack under intense sunlight and heat.

The thermal expansion and contraction of these materials under extreme temperature fluctuations also play a significant role. The dashboard experiences significant temperature swings, especially in direct sunlight. This repeated expansion and contraction creates stress points, eventually leading to cracks, particularly in areas with pre-existing weaknesses, such as seams or mounting points.

Furthermore, the specific formulation of the dashboard materials, including the amount of UV inhibitors added during manufacturing, directly affects its resistance to cracking. Older vehicles often lack the advanced UV protection found in newer models.

Repair Options: A Comparative Analysis

Several repair options exist, each with its own set of advantages and disadvantages. Choosing the appropriate method depends on the severity of the damage, the type of material, and the desired outcome.

1. DIY Repair Kits

Description: These kits typically include a filler compound, a texturing tool, and color-matching pigments. They are designed for small cracks and imperfections.

Pros:

- Cost-effective for minor damage.

- Relatively easy to use for basic repairs.

Cons:

- The color match can be difficult to achieve, resulting in a visible repair.

- The repair may not be durable, especially in high-stress areas.

- Not suitable for large or complex cracks.

- The filler material's thermal expansion coefficient may differ from the original dashboard material, leading to further cracking over time.

Reliability: Low to moderate, depending on the user's skill and the quality of the kit.

2. Professional Crack Repair

Description: Involves a skilled technician using specialized tools and materials to repair the crack. This often includes cleaning the area, applying a flexible filler, matching the texture and color, and sealing the repair.

Pros:

- More durable and aesthetically pleasing than DIY repairs.

- Better color matching and texture replication.

- Suitable for a wider range of crack sizes and complexities.

Cons:

- More expensive than DIY kits.

- Requires a skilled technician for optimal results.

- May still be visible under close inspection.

Reliability: Moderate to high, depending on the technician's expertise and the quality of the materials used.

3. Dashboard Replacement

Description: Replacing the entire dashboard with a new or refurbished unit.

Pros:

- Provides a like-new appearance.

- Eliminates the cracked dashboard entirely.

Cons:

- Most expensive option.

- Labor-intensive installation, requiring the removal of numerous interior components.

- Potential for damage to other parts during the removal and installation process.

- Finding a matching dashboard for older vehicles can be challenging.

- Airbag deployment systems need to be carefully handled and recalibrated, adding to the complexity.

Reliability: High, provided the new dashboard is of good quality and the installation is performed correctly.

4. Dashboard Cover or Overlay

Description: A molded cover that fits over the existing dashboard, concealing the cracks.

Pros:

- Relatively inexpensive.

- Easy to install.

- Conceals existing damage effectively.

Cons:

- May not perfectly match the original dashboard's texture and color.

- Can alter the appearance of the interior.

- May affect airbag deployment if not properly designed.

- Can trap heat and exacerbate cracking in the long run.

- Sensor functionality (e.g., light sensors for automatic headlights) might be impacted depending on the design.

Reliability: Moderate, but may not be a long-term solution.

Detailed Repair Procedures and Material Considerations

For professional crack repair, consider the following steps:

- Cleaning: Thoroughly clean the area around the crack with a specialized plastic cleaner to remove dirt, grease, and any loose debris.

- Preparation: Widen the crack slightly to create a better bonding surface. Use a small rotary tool with a fine grinding bit for this purpose.

- Filler Application: Apply a flexible filler specifically designed for automotive plastics. Two-part epoxy fillers offer superior strength and durability. Ensure the filler is compatible with the dashboard material.

- Texturing: Use a texturing tool or a mold to replicate the original dashboard texture. Practice on a scrap piece of material to achieve a consistent result.

- Color Matching: Mix color pigments to precisely match the dashboard color. Use a spectrophotometer for accurate color matching. Apply the color in thin layers, allowing each layer to dry completely before applying the next.

- Sealing: Apply a clear coat sealant to protect the repair from UV radiation and wear.

Material Considerations:

- Filler: Choose a filler with high flexibility, UV resistance, and a similar thermal expansion coefficient to the dashboard material.

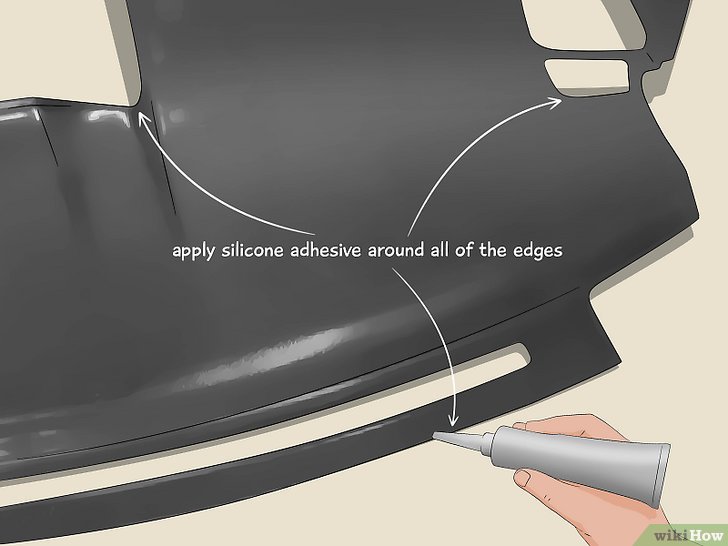

- Adhesive: Use a high-quality adhesive specifically designed for bonding plastics.

- Color Pigments: Opt for automotive-grade pigments that are resistant to fading and discoloration.

- Sealant: Apply a UV-resistant clear coat sealant to protect the repair from the elements.

Maintenance Tips and Preventative Measures

Preventing dashboard cracks is always better than trying to repair them. Here are some preventative measures:

- Parking in the Shade: Whenever possible, park your vehicle in the shade to minimize exposure to direct sunlight.

- Using a Sunshade: Use a sunshade to reflect sunlight away from the dashboard.

- Applying a UV Protectant: Regularly apply a UV protectant specifically designed for automotive interiors. These products help to block UV radiation and prevent the dashboard from drying out.

- Regular Cleaning: Clean the dashboard regularly with a mild detergent and water. Avoid using harsh chemicals or abrasive cleaners.

- Conditioning: Use a vinyl or leather conditioner to keep the dashboard supple and prevent it from drying out.

- Window Tinting: Consider installing window tinting to reduce the amount of UV radiation entering the vehicle.

Reliability Aspects

The reliability of a dashboard crack repair depends on several factors, including the quality of the materials used, the skill of the technician, and the severity of the damage. DIY repairs are generally less reliable than professional repairs. Dashboard replacements offer the highest level of reliability, but are also the most expensive.

It's important to choose a repair method that is appropriate for the type and severity of the damage. Minor cracks can often be repaired successfully with a DIY kit or professional crack repair. However, larger or more complex cracks may require dashboard replacement.

Future Trends in Dashboard Materials and Repair

The automotive industry is constantly evolving, and new materials and technologies are being developed to improve the durability and longevity of dashboards. Some of the future trends include:

- Advanced Polymers: The use of advanced polymers with enhanced UV resistance and thermal stability.

- Self-Healing Materials: The development of self-healing materials that can automatically repair minor cracks and scratches.

- 3D Printing: 3D printing technology could be used to create custom dashboard components and repair parts.

- Sustainable Materials: Increased use of sustainable and eco-friendly materials in dashboard construction.

Forward-Looking Note

The automotive industry is undergoing a rapid transformation, with a focus on sustainability, electrification, and autonomous driving. These trends will undoubtedly impact the design and construction of automotive interiors, including dashboards. We can expect to see the development of more durable, sustainable, and technologically advanced dashboard materials in the future. Furthermore, as vehicles become more connected and autonomous, the role of the dashboard will likely evolve, with a greater emphasis on information display and driver interaction. Automotive professionals need to stay abreast of these developments to provide the best possible service to their customers.