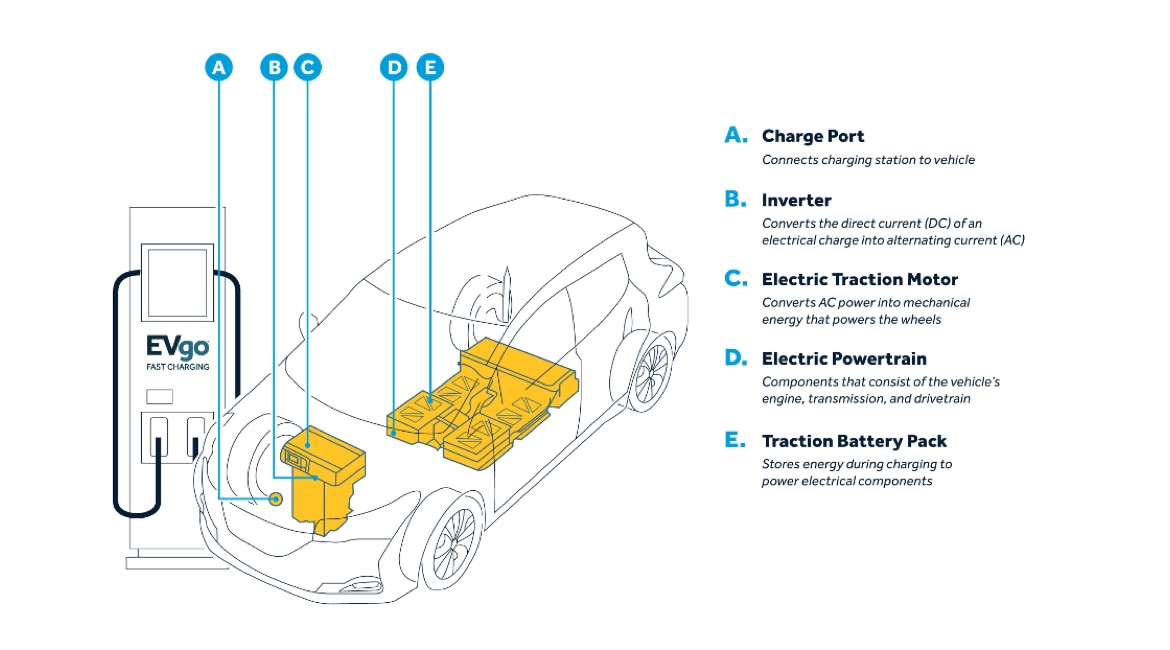

How Electric Cars Work Diagram

Alright, let's dive into the guts of an electric car. We're going to break down how these machines actually work, moving beyond the marketing buzzwords and getting into the nitty-gritty. This isn't about comparing brands or models; it's about understanding the core components and their functions. Think of it as taking apart an engine, but instead of pistons and valves, we're dealing with inverters and batteries.

The Electric Car Diagram: A Walkthrough

At its heart, an electric car's operation can be visualized with a relatively straightforward block diagram. Let's trace the flow of power, starting from the source:

1. The High-Voltage Battery Pack

This is the fuel tank of our electric vehicle. Unlike a gasoline engine's easily refillable tank, the battery pack stores energy in chemical form, ready to be released as electricity. These packs are typically composed of hundreds or even thousands of individual lithium-ion battery cells, arranged in series and parallel configurations to achieve the desired voltage and amperage.

Technical Deep Dive: Series connections increase the voltage (think of it like stacking batteries in a flashlight), while parallel connections increase the current capacity (allowing the battery to deliver more power for a longer time). The overall capacity is measured in kilowatt-hours (kWh), which is akin to gallons of gas in a traditional car – it dictates how far you can drive on a single charge.

Important Note: Handling high-voltage battery packs is extremely dangerous. Never attempt to disassemble or tamper with them unless you are a trained and qualified technician with the proper safety equipment. Seriously.

2. Battery Management System (BMS)

The BMS is the unsung hero of the EV. It’s a sophisticated electronic control unit (ECU) that constantly monitors the battery pack's health and performance. Its primary functions include:

- Voltage Monitoring: Tracking the voltage of each individual cell (or cell group) to identify any imbalances or failures.

- Temperature Monitoring: Ensuring the battery pack remains within its optimal temperature range for efficient operation and longevity. Excessive heat or cold can significantly degrade battery performance.

- State of Charge (SOC) Estimation: Calculating the remaining charge level, typically expressed as a percentage.

- State of Health (SOH) Estimation: Assessing the overall health and degradation of the battery pack over time. This helps predict its remaining lifespan.

- Cell Balancing: Redistributing charge between cells to maintain uniform voltage levels and prevent overcharging or over-discharging, which can damage the battery.

- Safety Control: Disconnecting the battery pack in case of overvoltage, undervoltage, overcurrent, or excessive temperature conditions to prevent damage or hazards.

The BMS is constantly communicating with other vehicle systems, providing crucial data and ensuring the safe and efficient operation of the battery pack.

3. DC-DC Converter

While the high-voltage battery pack provides the main power source, various components in the car, such as the lights, infotainment system, and auxiliary systems (e.g., air conditioning compressor), require a lower voltage, typically 12V or 24V. This is where the DC-DC converter comes in. It steps down the high-voltage DC from the battery pack to a lower, usable voltage for these accessories.

Technical Detail: A DC-DC converter uses switching regulators to efficiently convert voltage levels. Instead of simply dissipating excess energy as heat (like a resistor), it uses electronic switches (transistors) and inductors to store and release energy, resulting in significantly higher efficiency.

4. Inverter

This is a critical component in most electric car designs. The motor, which drives the wheels, typically uses alternating current (AC). However, the battery pack provides direct current (DC). The inverter bridges this gap by converting the high-voltage DC power from the battery into AC power for the motor.

The inverter not only converts DC to AC but also controls the frequency and voltage of the AC power, which in turn controls the speed and torque of the motor. Sophisticated control algorithms are used to optimize the motor's performance based on the driver's input.

Advanced Insights: Modern inverters use insulated-gate bipolar transistors (IGBTs) or silicon carbide (SiC) MOSFETs for their switching elements. SiC MOSFETs are becoming increasingly popular due to their higher efficiency and ability to operate at higher temperatures, leading to improved overall vehicle performance.

5. Electric Motor

The electric motor is the heart of the drivetrain. It takes the AC power from the inverter and converts it into mechanical energy to turn the wheels. There are several types of electric motors used in EVs, but the most common are:

- Permanent Magnet Synchronous Motor (PMSM): Highly efficient and offers excellent torque characteristics. Uses permanent magnets in the rotor, eliminating the need for brushes and slip rings, resulting in lower maintenance and higher reliability.

- Induction Motor: Robust and relatively inexpensive. Uses electromagnetic induction to generate torque in the rotor.

Regardless of the type, the motor's speed is directly related to the frequency of the AC power supplied by the inverter. The higher the frequency, the faster the motor spins.

Technical Point: EVs often use regenerative braking. When the driver slows down, the motor acts as a generator, converting the kinetic energy of the vehicle back into electricity. This electricity is then fed back into the battery pack, effectively increasing the car's range. The inverter plays a crucial role in controlling the regenerative braking process.

6. Gearbox (Transmission)

Unlike traditional internal combustion engine (ICE) cars with multi-speed transmissions, many EVs use a single-speed gearbox or a simple reduction gear. This is because electric motors produce high torque over a wide range of speeds, eliminating the need for multiple gear ratios.

The gearbox simply reduces the high rotational speed of the motor to a more suitable speed for the wheels, while also increasing the torque delivered to the wheels. Some high-performance EVs may use a two-speed gearbox to further optimize acceleration and top speed, but this is less common.

7. Charging System

Recharging the battery pack is, of course, essential. The charging system typically consists of two main components:

- Onboard Charger: Converts AC power from the grid into DC power suitable for charging the battery pack. The onboard charger has limitations on the amount of power it can handle, which determines the charging speed.

- Charging Port (Connector): The physical interface between the car and the charging station. Common charging standards include CHAdeMO, CCS (Combined Charging System), and Tesla's proprietary connector.

Charging can be done at different levels:

- Level 1 Charging: Using a standard household outlet (120V in North America). This is the slowest charging method, typically adding only a few miles of range per hour.

- Level 2 Charging: Using a 240V outlet, similar to what's used for dryers or ovens. Level 2 charging is significantly faster than Level 1, adding 20-30 miles of range per hour.

- DC Fast Charging (Level 3): Using high-power DC charging stations. DC fast charging can add hundreds of miles of range in a short amount of time (e.g., 30 minutes).

8. Thermal Management System

Both the battery pack and the motor generate heat during operation, especially under heavy load or during fast charging. A thermal management system is crucial for maintaining optimal operating temperatures and preventing overheating. This system typically uses liquid cooling to circulate coolant through the battery pack and motor, dissipating heat through a radiator or heat exchanger.

Technical Point: The thermal management system also plays a role in pre-heating the battery pack in cold weather. Battery performance is significantly reduced at low temperatures, so pre-heating helps to improve range and performance in cold climates.

Conclusion

Electric cars may seem complex at first, but understanding the fundamental components and their functions can demystify the technology. By tracing the flow of power from the battery pack to the wheels, we can appreciate the elegant engineering that makes these vehicles tick. Remember safety when working with high voltage systems. This overview provides a foundation for further exploration and understanding of the exciting world of electric vehicle technology.