How Many Crankshaft Sensors Are In A Car

The question "How many crankshaft sensors are in a car?" seems simple enough, but the answer, while usually straightforward, requires a bit of context. For the vast majority of modern passenger vehicles, the answer is one. However, understanding why this is the case, and what factors might lead to a different answer, requires a deeper dive into the function of the crankshaft sensor and the evolution of engine management systems.

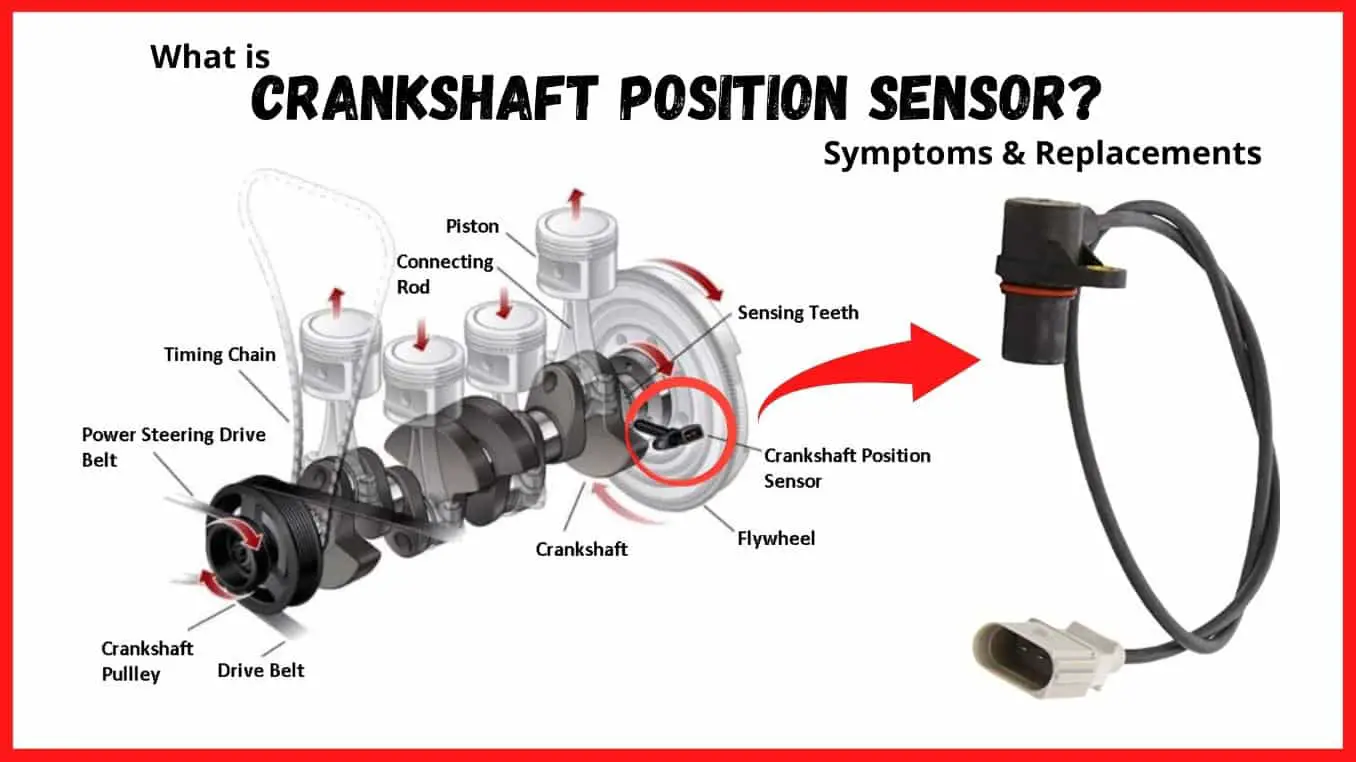

The Crankshaft Sensor: A Vital Component

The crankshaft sensor, often abbreviated as CKP sensor, plays a crucial role in modern internal combustion engines. Its primary function is to provide the engine control unit (ECU), sometimes also called the engine control module (ECM), with information about the crankshaft's position and rotational speed. This data is absolutely critical for precise ignition timing and fuel injection, the two pillars of efficient and powerful engine operation.

To understand why this information is so vital, consider the four-stroke engine cycle: intake, compression, combustion (power), and exhaust. Each of these strokes requires precise timing relative to the crankshaft's rotation. The ECU uses the crankshaft sensor data to determine when each cylinder is at the top of its compression stroke, enabling it to fire the spark plug at the optimal moment for combustion. Similarly, the ECU uses this data to determine when to inject fuel into the cylinder.

Without accurate crankshaft position information, the engine wouldn't know when to fire the spark plugs or inject fuel, leading to misfires, rough running, or even a complete inability to start. Think of it like trying to play a musical instrument without any sense of rhythm – the timing would be off, and the result would be chaotic and unpleasant.

Types of Crankshaft Sensors

There are two main types of crankshaft sensors: magnetic pickup sensors (also known as inductive sensors) and Hall effect sensors. Both types rely on detecting the passage of teeth or notches on a toothed wheel (reluctor ring) attached to the crankshaft.

- Magnetic Pickup Sensors: These sensors contain a coil of wire wrapped around a permanent magnet. As a tooth on the reluctor ring passes by the sensor, it disrupts the magnetic field, inducing a voltage pulse in the coil. The ECU reads these pulses to determine the crankshaft's position and speed. Magnetic pickup sensors are generally robust and relatively inexpensive, but their signal strength can weaken at low engine speeds.

- Hall Effect Sensors: These sensors use a semiconductor material that generates a voltage when exposed to a magnetic field. A reluctor ring with teeth or slots interrupts a magnetic field applied to the Hall effect sensor, creating a digital signal (on/off) that the ECU can interpret. Hall effect sensors provide a consistent signal even at low speeds and are less susceptible to interference than magnetic pickup sensors.

The choice between magnetic pickup and Hall effect sensors often depends on factors such as cost, operating environment, and the specific requirements of the engine management system.

Why Usually Just One? Redundancy and Camshaft Sensors

Given the critical nature of the crankshaft sensor, why doesn't every car have two or more for redundancy? The answer lies in a combination of factors, including cost, complexity, and the increasing sophistication of engine management systems.

While redundancy might seem like a good idea, adding a second crankshaft sensor would increase the cost and complexity of the engine design. It would require additional wiring, connectors, and processing power in the ECU. Furthermore, if the two sensors provided conflicting data, the ECU would need a sophisticated algorithm to determine which sensor was providing the correct information, further increasing complexity.

Instead of adding a second crankshaft sensor, many modern engines rely on a camshaft position sensor (CMP sensor) as a secondary source of information. The camshaft sensor monitors the position of the camshaft, which is directly linked to the crankshaft through the timing belt or chain. The camshaft sensor provides the ECU with information about which cylinder is on its intake stroke, allowing the ECU to distinguish between cylinders that are at the top of their compression stroke simultaneously (e.g., in a four-cylinder engine, cylinders 1 and 4, or 2 and 3). If the crankshaft sensor fails, the ECU can often use the camshaft sensor signal, in conjunction with other sensor data, to keep the engine running, albeit possibly in a degraded mode (e.g., reduced power, increased emissions).

This arrangement provides a level of indirect redundancy. While the camshaft sensor can't directly replace the crankshaft sensor's function of precisely determining crankshaft position and speed, it provides enough information to keep the engine operational in an emergency.

Exceptions to the Rule: When Might You Find More Than One?

While the vast majority of modern cars use a single crankshaft sensor, there are a few exceptions, primarily in high-performance or specialized applications. These exceptions are usually driven by the need for enhanced accuracy, reliability, or diagnostic capabilities.

- High-Performance Engines: In some high-performance engines, particularly those used in racing or extreme performance applications, multiple crankshaft sensors might be used to provide extremely precise crankshaft position information. This can be crucial for optimizing ignition timing and fuel injection at very high engine speeds, where even a small error in timing can have a significant impact on performance. In these cases, the sensors might be strategically placed to minimize the effects of torsional vibrations or other factors that could affect accuracy.

- Experimental or Research Vehicles: Automotive manufacturers and research institutions might use multiple crankshaft sensors in experimental or research vehicles to gather detailed data about engine behavior under different conditions. This data can be used to improve engine design, optimize control algorithms, and develop new technologies.

- Older or Specialized Designs: While rare, some older or highly specialized engine designs might have incorporated multiple crankshaft sensors for specific purposes. These designs are typically not found in modern passenger vehicles.

It's important to note that even in these exceptional cases, the use of multiple crankshaft sensors is typically driven by very specific and specialized requirements. For the vast majority of everyday cars, a single, well-designed crankshaft sensor provides sufficient accuracy and reliability for optimal engine operation.

Conclusion

In summary, while the answer to "How many crankshaft sensors are in a car?" is typically one, the reasons behind this answer are rooted in a complex interplay of factors, including cost, complexity, and the increasing sophistication of engine management systems. Modern engines often rely on a single, high-quality crankshaft sensor, complemented by a camshaft sensor, to provide the ECU with the necessary information for precise ignition timing and fuel injection. While exceptions exist in high-performance or specialized applications, the single-crankshaft-sensor design remains the standard for most passenger vehicles, offering a balance of performance, reliability, and cost-effectiveness.

Understanding the function of the crankshaft sensor and its role within the engine management system provides a valuable insight into the inner workings of modern automobiles and the engineering principles that underpin their design.