How Much Volt Does A Led Need

Light Emitting Diodes, or LEDs, have revolutionized automotive lighting. From subtle ambient lighting to powerful headlights, LEDs offer numerous advantages over traditional incandescent and halogen bulbs, including greater energy efficiency, longer lifespan, and instant-on capability. Understanding the voltage requirements of LEDs is crucial for proper installation, troubleshooting, and ensuring optimal performance in your vehicle. But, how much volt does a LED need in a car?

The Core Voltage Needs of an LED

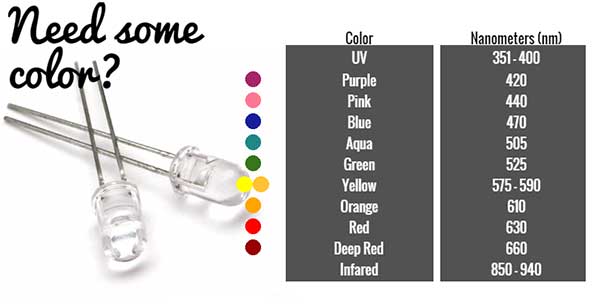

Unlike incandescent bulbs which operate on a relatively wide voltage range, LEDs are more sensitive to voltage fluctuations. Typically, a single LED requires a forward voltage of approximately 1.8 to 3.3 volts DC (Direct Current) to illuminate. The specific voltage depends on the LED's color and chemical composition. For example, red LEDs generally have a lower forward voltage (around 1.8-2.2V) compared to blue or white LEDs (around 3.0-3.3V). Understanding this voltage range is paramount when designing or modifying any automotive lighting system using LEDs.

However, directly connecting a single LED to a car's electrical system, which typically operates at 12V (or 24V in some heavy-duty vehicles), will instantly destroy it. LEDs are current-driven devices, meaning the amount of current flowing through them dictates their brightness and lifespan. Excessive current leads to overheating and premature failure. Therefore, a current-limiting device, usually a resistor or a constant current driver, is essential.

Calculating Resistor Values for Automotive LEDs

When using resistors, the goal is to drop the excess voltage from the car's electrical system (12V or 24V) down to the LED's required forward voltage while limiting the current to a safe level. The current rating is typically provided by the LED manufacturer (e.g., 20mA, 30mA). Ohm's Law (V = IR) provides the foundation for calculating the appropriate resistor value.

Here's a simplified example for a 12V system:

- Voltage Drop (VR): This is the difference between the supply voltage (12V) and the LED's forward voltage (VLED). VR = 12V - VLED

- LED Forward Current (ILED): Let's assume the LED requires 20mA (0.02A).

- Resistance (R): R = VR / ILED

Let's say you have a red LED with a forward voltage of 2V and a desired current of 20mA. The calculation would be:

- VR = 12V - 2V = 10V

- R = 10V / 0.02A = 500 ohms

Therefore, a 500-ohm resistor would be appropriate. In practice, it’s wise to select the next higher standard resistor value (e.g., 510 ohms) for added safety margin. Furthermore, consider the resistor's power rating. Power (P) is calculated as P = VR * ILED. In our example, P = 10V * 0.02A = 0.2W. A resistor with a power rating of 1/4W (0.25W) or higher would be suitable.

Important Note: This is a simplified calculation. Factors like voltage spikes in the car's electrical system and resistor tolerance can influence the actual current flowing through the LED. Using a multimeter to measure the current after installation is highly recommended.

Resistors vs. Constant Current Drivers

While resistors are a simple and inexpensive way to limit current, they are not the most efficient solution. Variations in the supply voltage (which are common in automotive systems due to alternator load changes) can affect the current flowing through the LED, leading to brightness fluctuations. Constant current drivers are a superior alternative. These drivers maintain a consistent current flow to the LED, regardless of voltage fluctuations within a specified range. This ensures consistent brightness and extends the LED's lifespan. They are especially beneficial for applications where consistent brightness is critical, such as headlights or daytime running lights (DRLs).

Automotive LED Lighting Systems: Beyond Single LEDs

Modern automotive LED lighting systems rarely use a single LED and resistor. Instead, they often employ complex circuits with multiple LEDs connected in series and/or parallel, controlled by sophisticated driver circuits. These systems are designed to provide optimal light output, beam pattern, and thermal management.

Series Connections: Connecting LEDs in series increases the total forward voltage required. For example, three LEDs each requiring 3V would need a total of 9V. This allows for more efficient use of the 12V supply. However, if one LED fails in a series circuit, the entire string will go out.

Parallel Connections: Connecting LEDs in parallel requires each LED to have its own current-limiting resistor. This is because LEDs are not perfectly identical, and variations in their forward voltage characteristics can lead to uneven current distribution. Without individual resistors, one LED could hog the current and burn out, leading to a cascade failure.

Troubleshooting LED Lighting Problems

When troubleshooting LED lighting problems in a vehicle, consider the following:

- Voltage Drop: Use a multimeter to check the voltage at the LED's terminals. If the voltage is significantly lower than expected, there may be a problem with the wiring, the resistor, or the power supply.

- Polarity: LEDs are polarity-sensitive. Ensure that the positive (+) and negative (-) leads are connected correctly. Reversing the polarity will prevent the LED from illuminating and may damage it.

- Bad Solder Joints: If you've installed the LEDs yourself, check for poor solder joints. Cold solder joints can cause intermittent connections and flickering.

- Overheating: LEDs generate heat, and excessive heat can shorten their lifespan. Ensure that the LEDs are properly heat-sinked or have adequate ventilation. High-performance LEDs often require a dedicated heat sink to dissipate heat effectively.

- Compatibility: Aftermarket LED bulbs might not be compatible with all vehicles, particularly those with advanced lighting control systems. Check the manufacturer's specifications and ensure that the bulb is designed to work with your vehicle's electrical system. Problems may arise like bulb-out warnings on the dashboard or hyper-flashing of turn signals. These issues often require the installation of load resistors or modifications to the vehicle's coding.

Replacing OEM Lighting with LEDs: A Word of Caution

Replacing factory-installed halogen or incandescent bulbs with LEDs can improve visibility and aesthetics. However, simply swapping bulbs without considering the electrical and optical characteristics can lead to problems. For example, LEDs have a different light distribution pattern than traditional bulbs. Using an LED bulb designed for a reflector-based halogen headlight in a projector housing can result in poor beam pattern and reduced visibility.

Furthermore, some vehicles use sophisticated bulb monitoring systems that detect when a bulb has failed. LEDs typically draw less current than halogen bulbs, which can trick the system into thinking the LED is burned out, resulting in a "bulb out" warning on the dashboard. To avoid these issues, use LED bulbs specifically designed for your vehicle's lighting system and consider installing load resistors to mimic the current draw of the original bulbs.

The Future of Automotive LED Lighting

Automotive LED lighting is constantly evolving, with manufacturers developing brighter, more efficient, and more sophisticated systems. Advanced technologies like adaptive headlights, matrix LED headlights, and laser headlights are becoming increasingly common in high-end vehicles. These systems use complex control algorithms and sensors to adjust the beam pattern and intensity of the light based on driving conditions, improving safety and visibility.

Understanding the voltage and current requirements of LEDs, as well as the principles of series and parallel connections, is essential for anyone working with automotive lighting systems. Whether you're a DIY enthusiast, a professional mechanic, or a car owner looking to upgrade your vehicle's lighting, a solid understanding of these concepts will help you make informed decisions and avoid costly mistakes. Always consult the manufacturer's specifications and follow safety precautions when working with electrical systems in your vehicle.