How To Check The Transmission Oil Level

Checking the transmission oil level is a fundamental maintenance task crucial for the longevity and smooth operation of any vehicle with an automatic transmission. While seemingly simple, the process requires careful attention to detail and understanding of the specific transmission type and vehicle manufacturer's recommendations. This article provides an in-depth guide for automotive professionals, encompassing technical specifications, engineering choices, real-world performance, alternative approaches, reliability considerations, maintenance tips, and future trends.

Understanding Transmission Fluid and its Role

Transmission fluid, often abbreviated as ATF (Automatic Transmission Fluid), is a highly specialized lubricant vital for the proper functioning of an automatic transmission. Its primary functions include:

- Lubrication: Reducing friction between moving parts such as gears, bearings, and clutches.

- Cooling: Dissipating heat generated by friction and hydraulic action.

- Hydraulic Power Transfer: Acting as the hydraulic medium to engage clutches and bands, enabling gear changes.

- Cleaning: Carrying away debris and contaminants to prevent wear and damage.

- Corrosion Prevention: Protecting metal surfaces from rust and corrosion.

Different transmission designs and manufacturers require specific types of ATF. Using the incorrect fluid can lead to severe transmission damage, including clutch slippage, overheating, and premature failure. Always consult the vehicle's owner's manual or a reliable parts database to determine the correct ATF specification.

Methods for Checking Transmission Oil Level

There are two primary methods for checking transmission fluid levels:

1. Dipstick Method

This is the most common and straightforward method, particularly prevalent in older vehicles. The process generally involves:

- Locating the Dipstick: The transmission dipstick is typically located in the engine compartment, often near the back of the engine. It's usually marked with a specific symbol (often a gear) or labeled "Transmission."

- Preparing the Vehicle: The vehicle should be parked on a level surface. The engine needs to be at operating temperature, and the transmission should be warmed up. This ensures an accurate reading. In some cases, the manufacturer specifies the engine should be running while checking the level. Always consult the owner's manual.

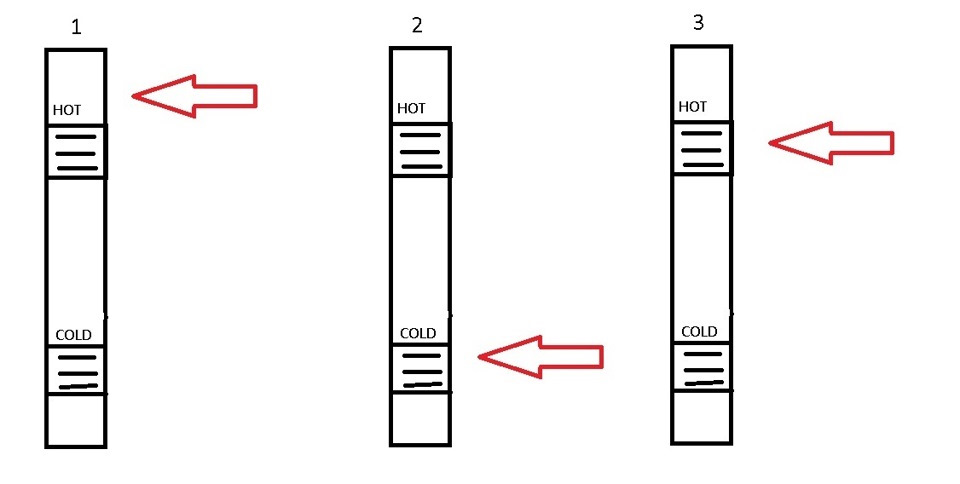

- Checking the Level: Remove the dipstick, wipe it clean with a lint-free rag, and reinsert it fully. Remove the dipstick again and observe the fluid level. The fluid level should be between the "MIN" and "MAX" or "COLD" and "HOT" marks on the dipstick.

- Adding Fluid (If Necessary): If the fluid level is low, add the correct type of ATF through the dipstick tube, using a funnel to prevent spills. Add fluid in small increments, rechecking the level after each addition until the correct level is reached.

Pros: Simple, readily accessible, allows visual inspection of fluid condition (color, smell).

Cons: Requires physical access to the dipstick, can be messy, relies on accurate dipstick calibration.

2. Fill Plug/Level Check Plug Method

Many newer vehicles, particularly those with sealed transmissions or complex electronic controls, utilize a fill plug/level check plug system. This method eliminates the need for a dipstick. The process involves:

- Locating the Fill Plug and Level Check Plug: These plugs are typically located on the side of the transmission case. Consult the vehicle's service manual for precise locations.

- Preparing the Vehicle: Similar to the dipstick method, the vehicle should be level, and the transmission should be at operating temperature. Specific temperature ranges are often specified by the manufacturer and may require the use of a diagnostic scan tool to monitor the transmission fluid temperature.

- Checking the Level: Remove the level check plug. If fluid begins to drip out slowly, the fluid level is correct. If no fluid drips out, add fluid through the fill plug until it begins to drip from the level check plug.

- Adding Fluid (If Necessary): Using a pump or specialized fluid transfer tool, add the correct type of ATF through the fill plug. Continue adding fluid until it drips steadily from the level check plug. Replace both plugs, torquing them to the manufacturer's specifications.

Pros: More precise level indication, eliminates potential for dipstick calibration errors, allows for temperature-compensated level adjustment.

Cons: Requires specialized tools and knowledge, can be more difficult to access, relies on accurate temperature monitoring and fluid viscosity/temperature relationship.

Technical Considerations and Engineering Choices

The choice between a dipstick and a fill plug system reflects several engineering considerations:

- Transmission Design: Modern transmissions are often more complex, with tighter tolerances and more sophisticated electronic controls. The fill plug method allows for more precise fluid level control, which is critical for optimal performance and longevity.

- Sealed Transmissions: Some manufacturers design "sealed" transmissions with the intention of extending service intervals and reducing maintenance requirements. These transmissions typically use the fill plug method and require special procedures for fluid changes. It is important to note that "sealed" does not mean "maintenance-free."

- Ease of Manufacturing: Eliminating the dipstick tube can simplify the manufacturing process and reduce component costs.

- Vehicle Integration: Packaging constraints in the engine compartment may make it difficult to accommodate a dipstick tube.

Furthermore, the type of ATF used is carefully engineered to match the specific requirements of the transmission. Factors considered include viscosity, friction modifiers, oxidation stability, and compatibility with transmission components. Modern ATF formulations often contain synthetic base oils and advanced additive packages to provide superior performance and durability.

Real-World Performance and Reliability

Maintaining the correct transmission fluid level is crucial for real-world performance and reliability. Low fluid levels can lead to:

- Clutch Slippage: Insufficient hydraulic pressure can cause clutches to slip, resulting in poor acceleration, jerky shifting, and increased wear.

- Overheating: Reduced fluid volume reduces cooling capacity, leading to overheating and accelerated fluid degradation.

- Transmission Damage: Prolonged operation with low fluid can cause severe damage to gears, bearings, and other internal components.

Overfilling the transmission can also be detrimental. Excess fluid can cause foaming, which reduces its lubricating and cooling properties. It can also create excessive pressure, potentially damaging seals and other components.

Maintenance Tips for Automotive Professionals

Here are some essential maintenance tips for automotive professionals:

- Always Use the Correct ATF: Refer to the vehicle's owner's manual or a reliable parts database to determine the correct ATF specification.

- Check for Leaks: Inspect the transmission for any signs of leaks, such as fluid puddles or dampness around seals and connections.

- Monitor Fluid Condition: Regularly check the fluid condition. Dark, discolored, or burnt-smelling fluid indicates degradation and the need for a fluid change.

- Follow Manufacturer's Recommendations: Adhere to the manufacturer's recommended service intervals for transmission fluid changes.

- Use Proper Tools and Procedures: Employ the correct tools and procedures for checking and changing transmission fluid, including torque wrenches and fluid transfer equipment.

- Temperature Monitoring: When using the fill plug method, use a scan tool to accurately monitor transmission fluid temperature and adjust the fluid level accordingly.

Future Trends in Transmission Fluid Level Monitoring

The automotive industry is moving towards more sophisticated and integrated monitoring systems. Future trends in transmission fluid level monitoring include:

- Electronic Level Sensors: Integrated sensors that continuously monitor the fluid level and provide real-time feedback to the vehicle's control system.

- Predictive Maintenance: Algorithms that analyze sensor data and predict potential transmission problems before they occur.

- Remote Diagnostics: The ability to remotely monitor transmission fluid levels and other parameters through telematics systems.

- Self-Sealing Transmissions: Advanced sealing technologies that minimize the risk of leaks and reduce the need for frequent fluid checks.

These advancements will improve vehicle reliability, reduce maintenance costs, and enhance the overall driving experience.

Conclusion

Checking the transmission fluid level is a critical maintenance task that automotive professionals must understand thoroughly. By understanding the different methods, technical considerations, and potential issues, professionals can ensure the proper operation and longevity of their customers' vehicles. As the automotive industry continues to evolve, staying abreast of new technologies and best practices is essential for providing high-quality service and maintaining a competitive edge. The shift towards electronically monitored and potentially self-adjusting systems signifies a future where manual fluid checks may become less frequent, but understanding the underlying principles of transmission lubrication and hydraulics will remain a core competency for automotive technicians.