How To Install Belt Tensioner

The rhythmic hum of an engine, the satisfying click of a seatbelt, the open road beckoning – these are sensations deeply ingrained in the automotive enthusiast's soul. But beneath the chrome and comfort, lies a complex web of mechanics, each component playing a crucial role. Today, we're diving into a seemingly mundane, yet vital task: installing a belt tensioner. However, we won't just cover the nuts and bolts; we'll explore how this seemingly simple procedure is evolving in the face of revolutionary changes sweeping the automotive landscape.

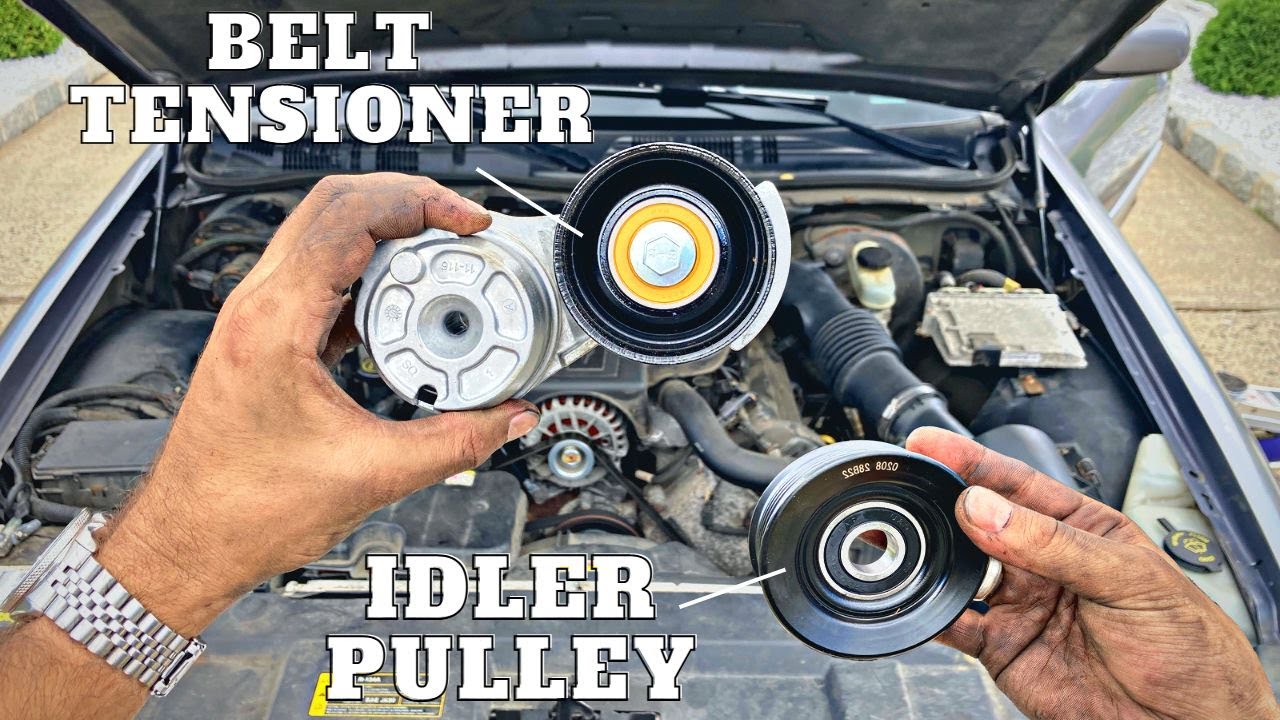

The Humble Belt Tensioner: A Foundation of Automotive Reliability

The belt tensioner, often overlooked, is a unsung hero in the internal combustion engine (ICE) realm. Its primary function is to maintain the correct tension on the serpentine belt, which drives essential accessories like the alternator, power steering pump, air conditioning compressor, and water pump. Proper tension ensures efficient operation of these systems and prevents premature belt wear or failure. A faulty tensioner can lead to a host of problems, from reduced power steering assist to overheating and a complete breakdown.

The Standard Procedure: A Step-by-Step Guide (with a Twist)

Before we delve into the future, let's briefly review the traditional process of replacing a belt tensioner. This is a general guide and may vary depending on your vehicle's make and model. Always consult your vehicle's service manual.

- Safety First: Disconnect the negative battery terminal. This prevents accidental shorts and potential injury.

- Locate the Tensioner: Refer to your vehicle's service manual to pinpoint the tensioner's location. It's usually near the front of the engine.

- Release the Belt Tension: Use a wrench or socket to rotate the tensioner arm, relieving tension on the serpentine belt. Many tensioners have a square drive specifically for this purpose.

- Remove the Belt: Carefully slide the belt off the pulleys, noting its routing for reinstallation. A diagram or photo can be helpful.

- Remove the Old Tensioner: Unbolt the old tensioner from its mounting bracket. Be mindful of any spacers or shims.

- Install the New Tensioner: Install the new tensioner, ensuring proper alignment and torque specifications. Use a torque wrench to avoid over-tightening.

- Reinstall the Belt: Route the serpentine belt correctly, ensuring it's seated properly in all the pulley grooves.

- Release the Tensioner and Verify: Slowly release the tensioner arm, allowing it to apply tension to the belt. Double-check the belt routing and tension.

- Reconnect the Battery: Reconnect the negative battery terminal.

- Test Drive: Start the engine and listen for any unusual noises. Check that all accessories are functioning correctly.

Now, here's the twist: While this procedure remains largely unchanged for ICE vehicles, the increasing prevalence of electric vehicles (EVs) and hybrid systems is significantly impacting the role and relevance of the traditional belt tensioner.

The Electric Revolution: A Shifting Landscape

EVs, by their very nature, eliminate the need for many of the components driven by the serpentine belt in a conventional ICE vehicle. There's no alternator, no power steering pump (typically replaced with an electric unit), and no traditional air conditioning compressor. This means no serpentine belt and, therefore, no belt tensioner in the traditional sense.

Hybrid vehicles present a more nuanced picture. Many hybrid systems still rely on an ICE for propulsion, especially during higher-speed driving or when extra power is needed. In these cases, a serpentine belt and tensioner are often present, although their role may be reduced compared to a purely ICE vehicle. Some hybrids use electric compressors and power steering, further lessening the reliance on the belt-driven system.

The Rise of Electromechanical Tensioners and Integrated Systems

However, the automotive industry isn't simply abandoning the concept of tensioning. Instead, it's adapting and innovating. In some advanced hybrid systems, we're seeing the emergence of electromechanical tensioners. These systems use an electric motor to control belt tension, offering more precise and dynamic adjustment. This can improve efficiency and reduce wear.

Furthermore, as manufacturers strive for greater efficiency and compactness, we're seeing the integration of various components into single units. For example, an electric motor might directly drive a water pump or air conditioning compressor, eliminating the need for a belt and tensioner altogether. This trend towards integrated systems is likely to accelerate as EV and hybrid technology matures.

Smart Automotive Solutions and Predictive Maintenance

The future of automotive maintenance is inextricably linked to smart automotive solutions and predictive maintenance. Imagine a vehicle that constantly monitors the condition of its belt tensioner using sensors. These sensors could measure belt tension, vibration, and temperature. By analyzing this data, the vehicle could predict when the tensioner is likely to fail and alert the driver or schedule a service appointment proactively.

This type of predictive maintenance can significantly reduce downtime and prevent costly repairs. It also aligns with the growing trend of over-the-air (OTA) updates and remote diagnostics. In the future, a technician might be able to diagnose a tensioner problem remotely and even update the tensioner's control software to optimize its performance.

Challenges and Opportunities

The transition to EVs and advanced hybrid systems presents both challenges and opportunities for automotive technicians. The decreasing reliance on traditional mechanical components means that technicians need to acquire new skills in areas like electrical systems, battery technology, and software diagnostics. Upskilling and continuous learning are crucial for staying relevant in this rapidly evolving field.

However, this also presents an opportunity to specialize in emerging technologies. Technicians who become experts in EV and hybrid systems will be in high demand. Moreover, the increasing complexity of modern vehicles means that there will always be a need for skilled diagnosticians who can troubleshoot intricate problems.

One realistic challenge is the availability of training and resources for technicians. The automotive industry needs to invest in comprehensive training programs to ensure that technicians have the skills they need to work on these new technologies. Furthermore, access to reliable diagnostic tools and technical information is essential.

Another challenge is the affordability of EVs and advanced hybrid systems. While the cost of these vehicles is decreasing, they are still generally more expensive than their ICE counterparts. Making these technologies more accessible to a wider range of consumers is crucial for accelerating the transition to a cleaner and more sustainable transportation system.

Inspiring a New Generation of Automotive Professionals

The automotive industry is undergoing a profound transformation, driven by innovation and a commitment to sustainability. This is an exciting time to be involved in the field. We need to inspire a new generation of automotive professionals who are passionate about technology and dedicated to building a better future. This includes emphasizing the role of sustainability, ethical considerations, and the potential to shape the future of mobility.

Let's move beyond simply replacing parts. Let's empower technicians to be problem solvers, data analysts, and innovators. Let's create a culture of continuous learning and collaboration, where technicians are encouraged to share their knowledge and contribute to the development of new technologies.

A Visionary Note: The Future of Mobility

Imagine a world where vehicles are seamlessly integrated into a smart transportation ecosystem. Autonomous driving, connected vehicles, and intelligent infrastructure will work together to optimize traffic flow, reduce emissions, and enhance safety. In this world, the traditional belt tensioner may be a relic of the past, but the underlying principles of engineering excellence and a commitment to innovation will remain as important as ever.

The future of mobility is not just about building better cars; it's about creating a better world. It's about embracing new technologies, fostering collaboration, and inspiring a new generation of automotive professionals. Let's embrace the change and build a future where transportation is safe, sustainable, and accessible to all.