How To Replace A Blinker Bulb

Replacing a blinker bulb might seem like a simple task, but for automotive professionals, understanding the nuances behind the design, functionality, and potential pitfalls is crucial. This article delves into the intricacies of blinker bulb replacement, exploring various bulb types, their engineering underpinnings, real-world performance, and future trends shaping automotive lighting.

Understanding Blinker Bulb Technology

The ubiquitous blinker bulb has evolved significantly over time. Initially, incandescent bulbs were the standard. These rely on a thin tungsten filament heated by an electric current until it glows. While inexpensive and producing a warm, easily visible light, incandescent bulbs suffer from relatively short lifespans and are energy inefficient. Their slow ramp-up time also posed a safety concern, especially compared to modern alternatives.

Halogen bulbs, an improvement over incandescent, use a halogen gas (usually iodine or bromine) to recycle tungsten vapor back onto the filament, extending its life and increasing light output. They are more efficient and brighter than incandescent bulbs, but still generate significant heat and have a limited lifespan compared to newer technologies.

Light Emitting Diodes (LEDs) have revolutionized blinker bulb technology. LEDs are semiconductor devices that emit light when an electric current passes through them. LEDs offer several advantages:

- Energy Efficiency: Consuming significantly less power than incandescent and halogen bulbs.

- Long Lifespan: LEDs can last for tens of thousands of hours, reducing the frequency of replacements.

- Instant-On: Providing immediate illumination, improving visibility and safety.

- Durability: Resistant to vibration and shock compared to fragile filament-based bulbs.

However, LEDs are more complex than traditional bulbs and require careful design to manage heat dissipation and ensure compatibility with vehicle electrical systems. They also tend to be more expensive upfront.

Important Note: Ensure proper polarity when installing LED bulbs, as they are polarity-sensitive. Reversing the polarity will prevent the bulb from illuminating and can potentially damage the LED driver circuit.

The Replacement Process: A Step-by-Step Guide

While the specific procedure varies depending on the vehicle make and model, the following steps provide a general guideline for replacing a blinker bulb:

- Safety First: Disconnect the negative terminal of the battery to prevent electrical shock or short circuits.

- Locate the Blinker Bulb Housing: Consult the vehicle's owner's manual for the exact location of the blinker bulb housing. It's typically located within the headlight or taillight assembly.

- Access the Bulb Socket: Depending on the vehicle, you may need to remove screws, clips, or panels to access the bulb socket. Some vehicles may require removing the entire headlight or taillight assembly.

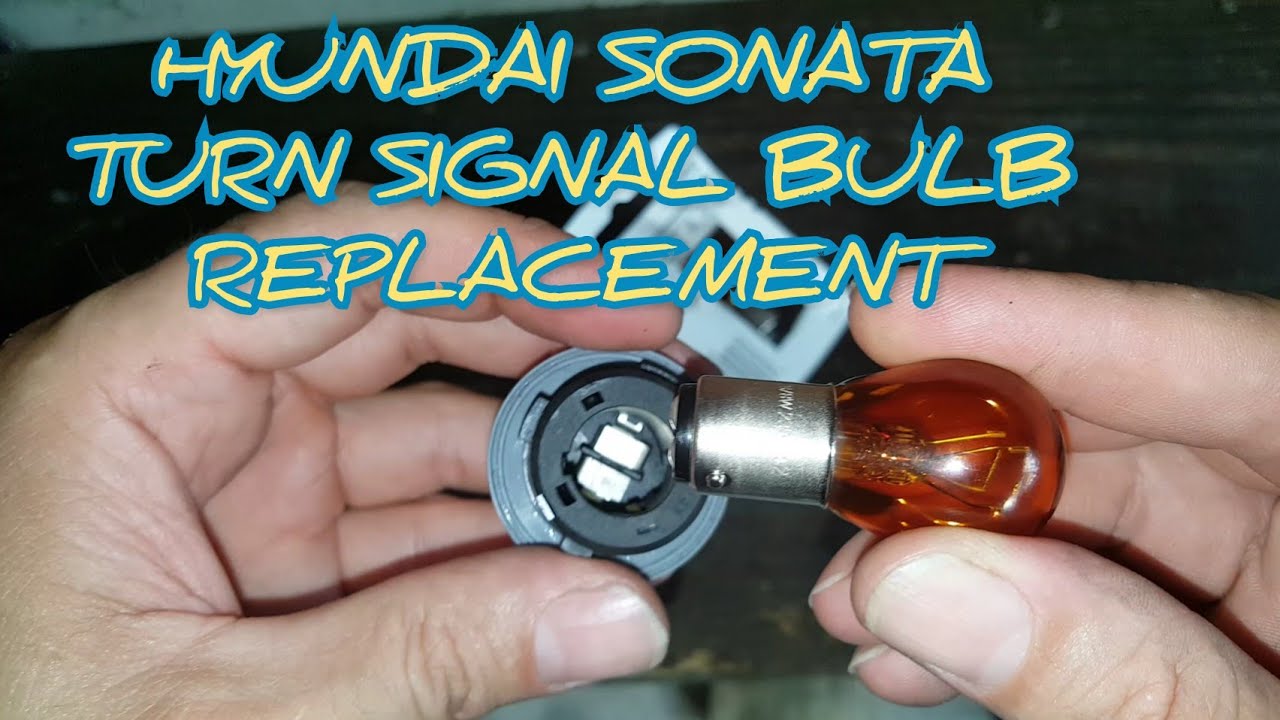

- Remove the Old Bulb: Carefully twist or pull the old bulb out of the socket. Note the orientation of the bulb for correct installation of the new bulb.

- Install the New Bulb: Insert the new bulb into the socket, ensuring it's properly seated. If it's an LED bulb, double-check the polarity.

- Reassemble the Housing: Reattach any screws, clips, or panels that were removed to access the bulb socket.

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Test the Blinker: Turn on the ignition and test the blinker to ensure the new bulb is functioning correctly.

- Verify Hyperflashing: Pay close attention to the blinker speed. Installing an LED bulb in a vehicle designed for incandescent bulbs might cause hyperflashing – a rapid blinking rate. This occurs because the LED's lower current draw is misinterpreted by the vehicle's flasher relay as a burnt-out bulb.

Addressing Hyperflashing: If hyperflashing occurs, you'll need to install load resistors in parallel with the LED bulbs. These resistors simulate the current draw of the original incandescent bulbs, preventing the flasher relay from misinterpreting the signal. However, load resistors generate heat and require careful mounting to prevent damage to surrounding components.

Pro Tip: When replacing bulbs, consider replacing them in pairs. This ensures consistent brightness and color between the left and right sides of the vehicle, enhancing visibility and safety.

Troubleshooting Common Issues

Even with careful installation, issues can arise. Here are some common problems and their potential solutions:

- Blinker Not Working: Check the bulb socket for corrosion or damage. Clean the contacts with a wire brush or contact cleaner. Also, verify the fuse associated with the blinker circuit. A blown fuse is a common cause of blinker failure.

- Hyperflashing (Even with Resistors): Ensure the load resistors are properly sized and connected. Some vehicles may require more powerful resistors than others.

- Flickering: Flickering can be caused by a loose connection in the bulb socket or a faulty flasher relay. Inspect the connections and replace the flasher relay if necessary.

- Bulb Not Seating Properly: Ensure the bulb is the correct type for the vehicle. Some bulb sockets are designed for specific bulb shapes and sizes.

Comparing Bulb Types: Pros and Cons

Let's compare the different blinker bulb technologies in more detail:

Incandescent Bulbs

Pros:

Low initial cost, readily available.

Cons:

Short lifespan, low energy efficiency, slow ramp-up time, fragile filament.

Halogen Bulbs

Pros:

Brighter than incandescent, longer lifespan than incandescent, relatively inexpensive.

Cons:

Shorter lifespan than LED, high heat generation, fragile glass envelope.

LED Bulbs

Pros:

Long lifespan, high energy efficiency, instant-on, durable, vibrant colors.

Cons:

Higher initial cost, potential compatibility issues (hyperflashing), requires heat management.

Reliability and Maintenance

Blinker bulb reliability is crucial for road safety. Regular inspection of all exterior lights, including blinkers, is recommended. Look for signs of dimming, flickering, or discoloration. Early detection of these issues can prevent bulb failure and potential accidents.

Maintenance Tips:

- Clean bulb sockets and contacts regularly to prevent corrosion.

- Use dielectric grease on bulb contacts to protect against moisture and corrosion.

- Replace bulbs in pairs to ensure consistent brightness and color.

- When upgrading to LED bulbs, choose reputable brands with built-in load resistors or purchase high-quality external resistors.

Future Trends in Automotive Lighting

The future of automotive lighting is heavily focused on LED technology and advanced lighting systems. Expect to see:

- More sophisticated LED designs: Including matrix LED headlights that can selectively dim or turn off individual LEDs to avoid blinding oncoming drivers.

- OLED (Organic Light Emitting Diode) technology: Offering even thinner and more flexible lighting solutions for taillights and interior lighting.

- Laser headlights: Providing extremely long-range illumination with high precision.

- Integrated lighting systems: Where lighting functions are seamlessly integrated into the vehicle's body panels.

- Smart lighting: Using sensors and algorithms to automatically adjust lighting based on driving conditions.

Conclusion

Replacing a blinker bulb might seem like a trivial task, but a thorough understanding of the underlying technology, potential issues, and future trends is essential for automotive professionals. As the automotive industry continues to evolve, staying abreast of these advancements will ensure you can provide the best possible service to your customers. The transition to solid-state lighting is inevitable, and mastering the nuances of LED technology will be crucial for maintaining and repairing future vehicles. Embracing these changes and adapting your skills accordingly will be key to success in the ever-evolving automotive landscape.