How To Use Spring Compressor

Understanding and Using a Spring Compressor: A Comprehensive Guide

Spring compressors are essential tools for anyone working on vehicle suspension systems. They allow you to safely and effectively compress coil springs, making tasks like replacing struts, shocks, or even the springs themselves, possible. Attempting these repairs without a spring compressor is extremely dangerous and can lead to serious injury. This guide will provide a detailed explanation of how to use a spring compressor safely and effectively.

Why You Need a Spring Compressor

Coil springs are under significant tension. When a strut or shock absorber assembly is disassembled, the spring will rapidly decompress, releasing a tremendous amount of energy. Without proper compression, this energy release can cause the spring to become a projectile, potentially causing severe injury or property damage. A spring compressor provides a controlled way to relieve this tension.

Types of Spring Compressors

Several types of spring compressors are available, each with its own advantages and disadvantages. Understanding the differences is crucial for selecting the right tool for the job.

- MacPherson Strut Spring Compressors (Internal): These are typically used by professionals. They are inserted inside the coil spring and expand outwards to compress it. They generally offer better safety and control but require specific adapters for different spring sizes.

- External Spring Compressors (Jaw-Type): These are the most common type for DIYers. They consist of two or more jaws that hook onto the coils of the spring and are tightened using a threaded rod. They are relatively inexpensive and versatile, but require careful attention to safety as they can slip if not properly positioned.

- Wall-Mounted Spring Compressors: These are heavy-duty compressors that are bolted to a wall or workbench. They offer excellent stability and safety but are not portable.

Choosing the Right Spring Compressor

Consider these factors when selecting a spring compressor:

- Type of Vehicle: Different vehicles have different spring designs and sizes. Ensure the compressor you choose is compatible with your vehicle.

- Spring Diameter and Length: Check the compressor's specifications to ensure it can handle the diameter and length of your coil springs.

- Safety Features: Look for compressors with safety features like safety pins or locking mechanisms to prevent slippage.

- Quality and Durability: Invest in a quality compressor from a reputable manufacturer. A cheap compressor may be more likely to fail, posing a safety risk.

Step-by-Step Guide: Using an External Spring Compressor (Jaw-Type)

This guide focuses on the most common type of spring compressor – the external jaw-type. While relatively simple to use, following these steps carefully is crucial for safety.

- Safety First! Wear safety glasses and gloves. Perform the work in a well-lit and uncluttered area. Make sure you have enough space to work safely.

- Inspect the Compressor: Before each use, thoroughly inspect the spring compressor for any signs of damage, such as cracks, bent threads, or worn jaws. Never use a damaged spring compressor.

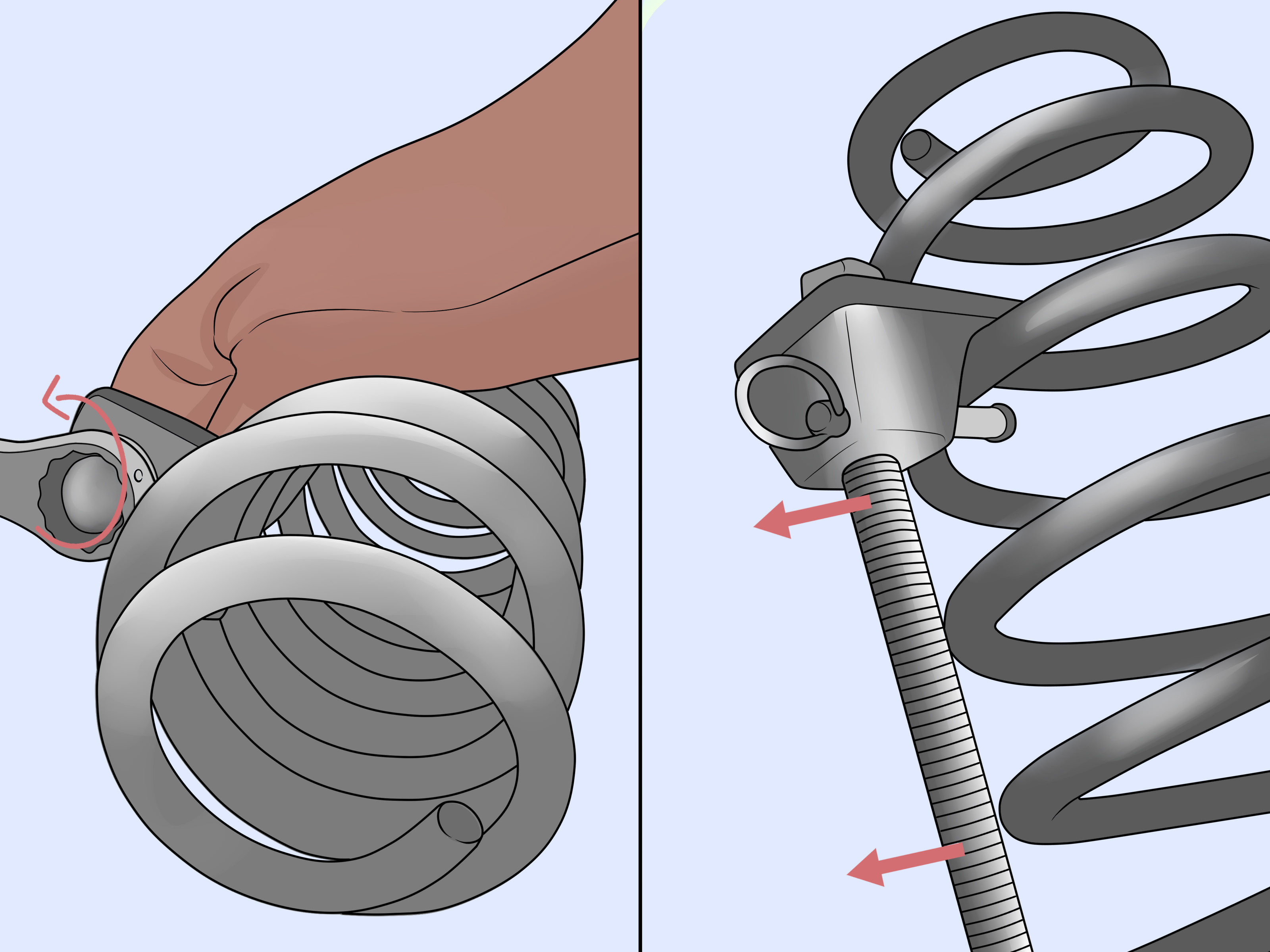

- Position the Jaws: Place the jaws of the compressor on opposite sides of the spring, ensuring they are securely hooked onto the coils. The jaws should be positioned as far apart as possible, within the safe operating range of the compressor, to distribute the load evenly. Important: Make sure the jaws are not overlapping on the same coil.

- Tighten Gradually: Using a wrench or socket, gradually tighten the threaded rod of the compressor, alternating between the jaws to compress the spring evenly. Avoid over-tightening one side, as this can cause the spring to buckle or the compressor to slip. Never use an impact wrench on a spring compressor. Apply even pressure.

- Monitor the Spring: As you compress the spring, carefully monitor its behavior. Ensure it is compressing straight and not buckling or bending excessively. If the spring appears unstable, stop immediately and reposition the jaws.

- Compress to Required Length: Compress the spring only enough to remove the strut mount or shock absorber. Compressing it excessively can damage the spring or the compressor. Refer to your vehicle's service manual for the correct compressed length.

- Secure the Spring (if applicable): Some spring compressors have safety pins or locking mechanisms. Engage these to secure the spring in the compressed position. This provides an extra layer of safety in case the compressor fails.

- Disassemble the Strut/Shock Assembly: Once the spring is safely compressed, you can now disassemble the strut or shock absorber assembly. Be careful when removing the nut on top of the strut, as it may still be under some pressure.

- Assembly and Decompression: After replacing the necessary components, carefully reassemble the strut or shock absorber assembly. Slowly release the tension on the spring compressor by loosening the threaded rod, alternating between the jaws to ensure even decompression. Monitor the spring closely during decompression to ensure it remains stable.

- Remove the Compressor: Once the spring is fully decompressed, carefully remove the spring compressor.

Safety Precautions: Spring Compressor Don'ts

Ignoring safety precautions when using a spring compressor can have devastating consequences. Here's a list of things you should NEVER do:

- Never use an impact wrench. Using an impact wrench can damage the compressor and cause it to fail.

- Never overtighten the compressor. Overtightening can cause the spring to buckle or the compressor to slip.

- Never use a damaged compressor. A damaged compressor is a safety hazard.

- Never work alone. Having another person present can be helpful in case of an emergency.

- Never take shortcuts. Always follow the instructions carefully and take your time.

- Never point the spring towards yourself or others. Always direct the spring away from people and valuables.

- Never use heat on the spring or compressor. Heat can weaken the spring and the compressor, making them more likely to fail.

- Never attempt to compress a spring that is too large or too small for the compressor. Using the wrong size compressor can be dangerous.

Alternative: Professional Installation

If you are uncomfortable using a spring compressor or if you are not confident in your mechanical skills, it is best to have the work done by a qualified professional. A mechanic has the experience, tools, and knowledge to safely and effectively compress and decompress springs.

Choosing a professional installation will cost more than doing it yourself, but it eliminates the risk of injury and ensures the job is done correctly. The peace of mind is worth the extra expense for many.

Troubleshooting Common Issues

Even with careful preparation, you might encounter some issues when using a spring compressor. Here are a few common problems and how to address them:

- The compressor slips: This is usually caused by improper jaw placement or overtightening. Stop immediately, reposition the jaws, and try again. Ensure the jaws are securely hooked onto the coils and that you are tightening evenly.

- The spring buckles: This indicates that the spring is not compressing evenly. Stop immediately and reposition the jaws. Make sure the jaws are positioned as far apart as possible and that you are tightening evenly.

- The threaded rod is difficult to turn: This could be due to dirt, rust, or damage to the threads. Clean and lubricate the threads with a penetrating oil. If the threads are damaged, replace the compressor.

- The strut mount is stuck: Apply penetrating oil to the nut and let it soak for a few minutes. Use a breaker bar to loosen the nut. If the nut is still stuck, you may need to use a torch to heat it up (use extreme caution).

Conclusion

Using a spring compressor requires careful attention to safety and detail. By following these instructions and taking the necessary precautions, you can safely and effectively compress coil springs for various automotive repairs. However, if you are ever unsure about any aspect of the process, it is always best to consult with a qualified professional. Remember, your safety is paramount. By understanding how to use spring compressor, the types of compressors available, and the necessary safety precautions, you can perform this task with confidence and minimize the risk of injury. Good luck!