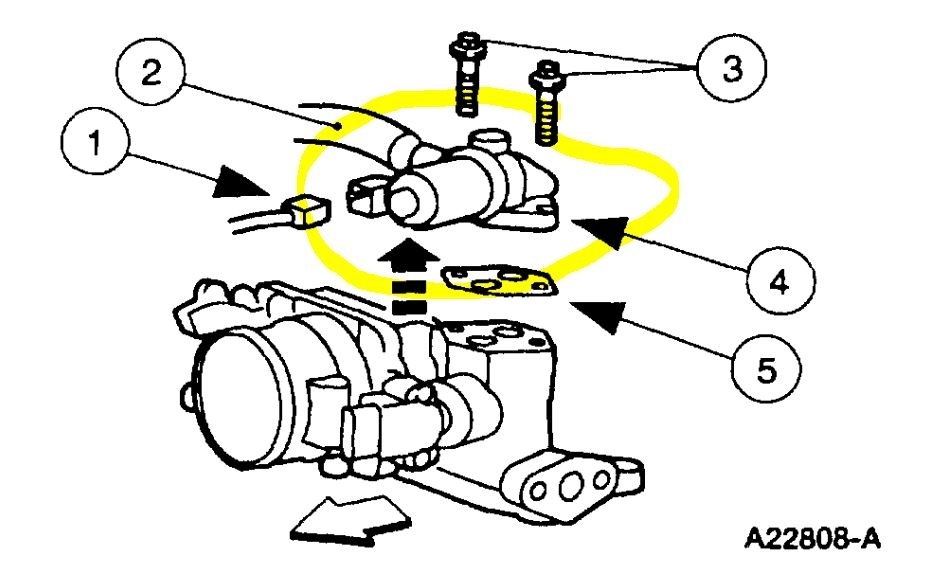

Idle Air Control Valve Location

The Idle Air Control (IAC) valve, a seemingly small component, plays a vital role in the smooth operation of gasoline engines, particularly during idling. Its primary function is to regulate the amount of air bypassing the throttle plate when the engine is idling, ensuring a stable and consistent engine speed regardless of varying engine loads or environmental conditions. Understanding its location is crucial for diagnosis, maintenance, and repair.

Common IAC Valve Locations Across Vehicle Makes

While the specific placement can vary depending on the vehicle's make, model, engine type, and year, there are common locations where you'll typically find the IAC valve. Understanding these common locations will significantly speed up the diagnostic process.

Throttle Body Mounted

This is the most prevalent location for IAC valves, especially on older vehicles and some modern engines. The IAC valve is usually bolted directly to the throttle body. This proximity allows for efficient control of airflow as it bypasses the closed throttle plate. Expect to find it either on the top, side, or underneath the throttle body assembly. Look for a small, cylindrical or rectangular component with an electrical connector and one or two vacuum hoses connected to it. A classic example is found on many 1990s and early 2000s General Motors vehicles with the 3.1L or 3.8L V6 engines. On these, the IAC valve is often a cylindrical unit mounted on the side of the throttle body.

Intake Manifold Mounted

In some vehicle designs, particularly those aiming for a more compact engine bay layout or optimized airflow, the IAC valve is mounted on the intake manifold. This location might be slightly less common than throttle body mounting, but it's still a common design choice. When found on the intake manifold, it is usually near the throttle body, ensuring it can still effectively regulate air bypassing the throttle plate. This design can be found on certain Honda and Toyota engines from the late 1990s and early 2000s.

Remote Location with Hoses

Less frequently, the IAC valve is situated in a more remote location, away from both the throttle body and the intake manifold. In such cases, it is connected to the throttle body and/or intake manifold via vacuum hoses. This design is more complex and less common, typically found in certain European vehicles or in vehicles with unique engine configurations. This configuration introduces a greater potential for vacuum leaks due to the increased number of hose connections.

Locating the IAC Valve: A Step-by-Step Guide

Finding the IAC valve is not difficult, but accuracy is necessary to ensure a correct diagnosis. Here's a practical guide to help you locate it effectively:

- Consult Your Vehicle's Repair Manual: This is the most reliable source of information. Your vehicle's repair manual (either a physical copy or a digital one) provides detailed diagrams and specific instructions for locating the IAC valve on your particular vehicle model.

- Visually Inspect the Throttle Body: Start by visually inspecting the throttle body. Look for a small valve or actuator attached to it. It will usually have an electrical connector and possibly one or two small vacuum hoses.

- Check the Intake Manifold: If you don't find it on the throttle body, move your search to the intake manifold, particularly near the throttle body connection point.

- Follow Vacuum Hoses: If you suspect a remote location, carefully trace vacuum hoses leading away from the throttle body or intake manifold. They might lead you to the IAC valve.

- Use Online Resources: Websites like YouTube, automotive forums, and online parts catalogs often provide visual aids and discussions that can help you identify the IAC valve location on your specific vehicle.

Identifying the IAC Valve

Once you've narrowed down the potential locations, look for the defining characteristics of the IAC valve:

- Electrical Connector: The IAC valve is an electrically controlled component, so it will always have an electrical connector with two or more wires.

- Small Size: Typically, the IAC valve is a relatively small component, significantly smaller than the throttle body or intake manifold.

- Cylindrical or Rectangular Shape: While the exact shape may vary, it is commonly either cylindrical or rectangular.

- Vacuum Hoses: Some IAC valves have small vacuum hoses connected to them, while others do not.

Common Problems Associated with IAC Valves

A faulty IAC valve can cause a range of drivability issues. Recognizing these symptoms is crucial for identifying a problem with the IAC valve.

- Rough or Unstable Idle: This is the most common symptom. The engine may idle too high, too low, or fluctuate erratically.

- Stalling: The engine may stall, especially when coming to a stop or when the air conditioning is turned on.

- Difficulty Starting: In some cases, a faulty IAC valve can make the engine difficult to start.

- Check Engine Light: A faulty IAC valve can trigger the check engine light. Diagnostic trouble codes (DTCs) related to the IAC valve, such as P0505, are common.

Maintenance and Repair

Maintaining a clean and functional IAC valve is essential for optimal engine performance. Here are some key points regarding maintenance and repair:

Cleaning the IAC Valve

Over time, the IAC valve can become clogged with carbon deposits and debris, hindering its ability to regulate airflow effectively. Cleaning the IAC valve is a relatively simple and inexpensive procedure that can often restore proper function. You can use a dedicated throttle body cleaner or carburetor cleaner to carefully remove the deposits. Be sure to follow the manufacturer's instructions and avoid spraying cleaner directly into the electrical connector.

Replacement

If cleaning does not resolve the issue, or if the IAC valve is damaged, replacement is necessary. When replacing the IAC valve, use a high-quality replacement part from a reputable brand. Always disconnect the battery before working on any electrical component in your vehicle. After installation, it may be necessary to perform an idle learn procedure using a diagnostic scan tool. This procedure allows the engine control unit (ECU) to relearn the IAC valve's parameters and ensure proper idle control. The cost of replacing an IAC valve can vary, but expect to pay between $50 and $200 for the part, plus labor if you're not doing it yourself. Labor costs can range from $50 to $150, depending on the complexity of the job and the hourly rate of the mechanic.

IAC Valve vs. Electronic Throttle Control

It's important to note that many modern vehicles utilize electronic throttle control (ETC), also known as drive-by-wire. In ETC systems, there is no mechanical linkage between the accelerator pedal and the throttle plate. Instead, the ECU controls the throttle plate position based on input from the accelerator pedal position sensor. In ETC systems, the traditional IAC valve is often eliminated, as the ECU can directly control the throttle plate to manage idle speed. Therefore, if you are working on a newer vehicle with ETC, you will not find a separate IAC valve.

Conclusion

The Idle Air Control (IAC) valve, while relatively small, plays a vital role in maintaining stable engine idle. Knowing its location, common problems, and basic maintenance procedures can save you time and money on repairs. Remember to consult your vehicle's repair manual for specific instructions and always exercise caution when working on your vehicle.