Idle Control Valve Replacement

The Idle Control Valve (ICV), also sometimes referred to as the Idle Air Control (IAC) valve, is a crucial component in modern internal combustion engines. Its primary function is to regulate engine speed when the throttle is closed, ensuring a smooth and consistent idle. While often overlooked, a malfunctioning ICV can lead to a host of frustrating issues, from stalling and rough idling to poor fuel economy. This article will delve into the intricacies of the ICV, exploring its function, symptoms of failure, replacement procedures, and best practices for maintaining optimal engine performance.

Understanding the Idle Control Valve

Before the advent of sophisticated electronic engine management systems, carburetors handled idle speed through a combination of jets and adjustment screws. However, with the introduction of fuel injection and stricter emissions regulations, the ICV became essential. This electromechanical device bypasses the main throttle plate, allowing a controlled amount of air into the intake manifold when the throttle is closed. The Engine Control Unit (ECU) monitors engine speed (RPM) and adjusts the ICV opening to maintain the desired idle speed, typically between 600 and 1000 RPM, depending on the vehicle.

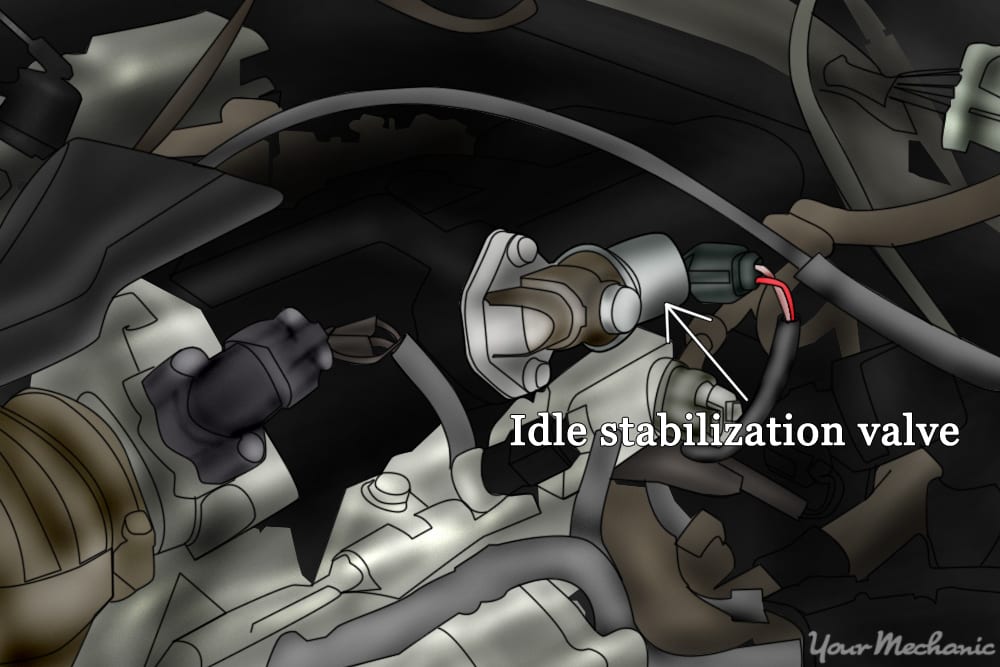

The ICV is typically located on or near the throttle body or intake manifold. Different types of ICVs exist, including rotary valves, stepper motors, and solenoid valves. Rotary valves use a rotating drum to regulate airflow, while stepper motors use a series of precise steps to position a valve. Solenoid valves rely on an electromagnetic coil to open and close an air passage. Regardless of the design, the fundamental principle remains the same: precise control of airflow to maintain a stable idle.

Symptoms of a Failing Idle Control Valve

Recognizing the signs of a failing ICV is crucial for preventing further engine damage and ensuring safe operation. Common symptoms include:

- Rough Idle: The engine may vibrate excessively or feel uneven when idling.

- Stalling: The engine may stall frequently, especially when coming to a stop or when the engine is cold.

- High Idle Speed: The engine may idle at a significantly higher RPM than normal.

- Fluctuating Idle Speed: The idle speed may surge up and down erratically.

- Difficulty Starting: A faulty ICV can sometimes make it difficult to start the engine.

- Check Engine Light: The ECU may trigger a check engine light and store diagnostic trouble codes (DTCs) related to the ICV. Common codes include P0505 (Idle Control System Malfunction), P0506 (Idle Air Control System RPM Lower Than Expected), and P0507 (Idle Air Control System RPM Higher Than Expected).

It's important to note that these symptoms can also be caused by other issues, such as vacuum leaks, faulty sensors, or a dirty throttle body. Therefore, a thorough diagnosis is essential to pinpoint the root cause of the problem.

Diagnosing an Idle Control Valve

Before replacing the ICV, it's wise to perform some basic diagnostic checks. Start by visually inspecting the ICV and its wiring for any signs of damage or corrosion. Check the vacuum hoses connected to the throttle body and intake manifold for leaks. A simple vacuum leak test can be performed using a spray bottle of soapy water; spray the hoses and connections while the engine is running, and look for bubbles indicating a leak.

Next, use a diagnostic scan tool to retrieve any stored DTCs. If ICV-related codes are present, investigate further. You can often use the scan tool to monitor the ICV's operation in real-time. The scan tool can show the commanded position of the ICV and the actual engine RPM. If the ICV is not responding to commands or if the RPM is not within the specified range, the ICV may be faulty.

In some cases, cleaning the ICV can resolve the issue. Over time, carbon deposits and debris can accumulate inside the valve, restricting airflow. Use a throttle body cleaner or carburetor cleaner to carefully clean the ICV. Be sure to disconnect the ICV from the electrical connector before cleaning and allow it to dry completely before reassembling.

Idle Control Valve Replacement Procedure

If cleaning the ICV doesn't solve the problem, replacement is often necessary. The replacement procedure can vary slightly depending on the vehicle, but the general steps are as follows:

- Disconnect the Negative Battery Cable: This is essential for safety and to prevent electrical damage.

- Locate the ICV: Refer to the vehicle's repair manual for the exact location of the ICV.

- Disconnect the Electrical Connector: Carefully disconnect the electrical connector from the ICV.

- Remove the ICV: The ICV is typically held in place by screws or bolts. Remove the fasteners and carefully detach the ICV from the throttle body or intake manifold.

- Install the New ICV: Install the new ICV in the reverse order of removal. Ensure that the mounting surfaces are clean and that the ICV is properly seated. Use new gaskets or O-rings if provided.

- Reconnect the Electrical Connector: Reconnect the electrical connector to the ICV.

- Reconnect the Negative Battery Cable: Reconnect the negative battery cable.

- Start the Engine: Start the engine and allow it to idle for a few minutes. Monitor the idle speed and listen for any unusual noises.

- Clear Diagnostic Trouble Codes: Use a diagnostic scan tool to clear any stored DTCs.

Important Note: Some vehicles may require an idle learn procedure after replacing the ICV. This procedure allows the ECU to recalibrate the ICV and optimize idle speed. Consult the vehicle's repair manual for specific instructions on performing the idle learn procedure.

Choosing a Replacement ICV

When selecting a replacement ICV, it's crucial to choose a high-quality part from a reputable manufacturer. Genuine OEM (Original Equipment Manufacturer) ICVs are generally the best option, as they are designed and tested to meet the vehicle's exact specifications. However, OEM parts can be expensive. Aftermarket ICVs from reputable brands like Bosch, Delphi, and Standard Motor Products can offer a more affordable alternative. Be wary of cheap, generic ICVs, as they may not perform as well or last as long.

Maintenance and Prevention

Regular maintenance can help prevent ICV failure and extend its lifespan. Cleaning the throttle body and intake manifold periodically can help prevent carbon deposits from accumulating in the ICV. Using high-quality fuel and performing regular engine tune-ups can also contribute to a healthy ICV. Avoid prolonged periods of idling, as this can accelerate carbon buildup.

Real-World Examples and Cost Considerations

The cost of replacing an ICV can vary depending on the vehicle, the type of ICV, and the labor rates of the mechanic. A typical ICV replacement can cost anywhere from $150 to $500, including parts and labor. For example, replacing the ICV on a BMW 3 Series might cost more than replacing it on a Honda Civic due to differences in parts prices and labor complexity.

Many DIY enthusiasts can perform the ICV replacement themselves, saving on labor costs. However, it's important to have a good understanding of automotive repair procedures and to use the correct tools. If you're not comfortable working on your vehicle, it's best to entrust the repair to a qualified mechanic.

Conclusion

The Idle Control Valve is a vital component for maintaining smooth and efficient engine operation. By understanding its function, recognizing the symptoms of failure, and performing regular maintenance, you can ensure that your engine idles smoothly and reliably for years to come. Whether you're a seasoned mechanic or a car enthusiast, knowing how to diagnose and replace an ICV is a valuable skill that can save you time and money.