Is The Radiator Fan Always On

The simple answer to the question, "Is the radiator fan always on?" is no. However, the nuances of automotive cooling systems and the evolution of engineering solutions warrant a deeper dive into the specifics. Modern vehicles employ a variety of strategies to manage engine temperature, and the operation of the radiator fan is a critical component of that system.

Understanding Radiator Fan Systems

Traditionally, radiator fans were mechanically driven, directly coupled to the engine via a belt. These fans ran whenever the engine was running, regardless of the actual cooling needs. While simple and reliable, this design suffered from several drawbacks, primarily inefficiency and noise. The constant operation of the fan consumed engine power, reducing fuel economy, and generated unnecessary noise, especially at higher engine speeds.

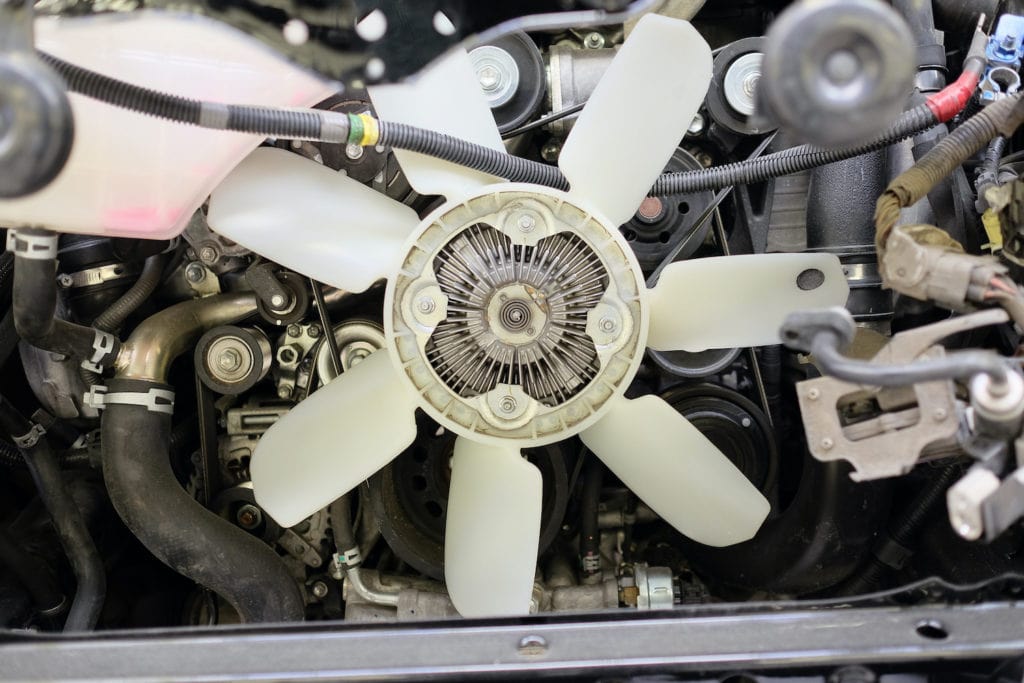

Viscous Fan Clutches

To address the inefficiencies of purely mechanical fans, viscous fan clutches were introduced. These clutches, often silicone-based, provided a variable degree of coupling between the engine and the fan. At lower temperatures, the clutch would slip, reducing the fan's speed and therefore its power consumption and noise. As engine temperature increased, the silicone fluid would become more viscous, increasing the coupling and causing the fan to spin faster, providing more cooling.

Pros of Viscous Fan Clutches:

- Improved efficiency compared to direct-drive fans.

- Reduced noise at lower engine temperatures.

- Relatively simple and reliable design.

Cons of Viscous Fan Clutches:

- Still consume engine power, even when partially disengaged.

- Can be prone to failure, especially due to silicone fluid leaks.

- Less precise temperature control compared to electric fans.

Electric Radiator Fans

The most common type of radiator fan in modern vehicles is the electrically driven fan. These fans are powered by an electric motor and controlled by the engine control unit (ECU). The ECU monitors various engine parameters, primarily coolant temperature, and activates the fan only when cooling is necessary. This allows for far greater precision and efficiency compared to mechanical or viscous fan systems. Electric fans can often operate at multiple speeds, further optimizing cooling performance and minimizing power consumption. PWM (Pulse Width Modulation) is a common technique used to control the fan speed. The ECU varies the duty cycle of the voltage applied to the fan motor, effectively controlling its speed from zero to maximum.

Pros of Electric Radiator Fans:

- Highly efficient, only operating when needed.

- Precise temperature control.

- Reduced noise.

- Can operate independently of engine speed, providing cooling even when the vehicle is stationary.

- Allows for features such as after-run cooling, where the fan continues to operate after the engine is shut off to prevent heat soak.

Cons of Electric Radiator Fans:

- More complex system, requiring sensors, ECU control, and wiring.

- Potential for electrical failures, such as motor burnout, relay failures, or wiring issues.

- Can draw significant current from the vehicle's electrical system, potentially straining the alternator.

Technical Specifications and Engineering Choices

The size and type of radiator fan used in a vehicle are carefully chosen based on the engine's heat output, the vehicle's weight and intended use, and the overall design of the cooling system. Fan diameter, blade design (number of blades, pitch), and motor power are all key factors. Automakers often use computational fluid dynamics (CFD) simulations to optimize fan design and ensure adequate airflow through the radiator. The amperage draw of the electric fan is also a crucial consideration for the vehicle's electrical system. A high-performance vehicle with a large engine may require a fan that draws 20-30 amps or more, necessitating a robust alternator and wiring.

Fan Control Strategies

The ECU uses sophisticated algorithms to control the electric radiator fan. These algorithms typically consider the following parameters:

- Coolant temperature sensor readings.

- Intake air temperature.

- Vehicle speed.

- Air conditioning system operation (the fan is often activated when the AC is turned on).

- Engine load.

Based on these inputs, the ECU determines the appropriate fan speed to maintain optimal engine temperature. Some vehicles also employ a second, smaller electric fan to cool the air conditioning condenser. This fan operates independently of the radiator fan and is controlled by the air conditioning system.

Real-World Performance and Reliability

In real-world driving conditions, electric radiator fans offer significant advantages in terms of fuel economy and noise reduction. The ability to precisely control the fan's operation based on actual cooling needs minimizes parasitic losses and reduces unnecessary noise. However, the reliability of electric fan systems is crucial. A malfunctioning fan can lead to engine overheating and potential damage. Regular maintenance, including inspection of wiring, connectors, and relays, is essential.

Troubleshooting Electric Radiator Fan Issues

Diagnosing electric radiator fan problems typically involves:

- Checking the fan motor for continuity.

- Testing the fan relay.

- Verifying the coolant temperature sensor readings.

- Inspecting the wiring for damage or corrosion.

- Scanning the ECU for fault codes related to the cooling system.

A common failure mode is a burned-out fan motor, often caused by excessive use or overheating. Relay failures are also relatively common and can be easily diagnosed with a multimeter. Wiring issues, such as corroded connectors or broken wires, can also prevent the fan from operating correctly. Proper diagnosis and repair are essential to ensure the engine cooling system functions as intended.

Maintenance Tips

To ensure the long-term reliability of the radiator fan system, consider the following maintenance tips:

- Regularly inspect the fan blades for damage or debris.

- Check the wiring and connectors for corrosion or damage.

- Test the fan operation periodically, especially during hot weather.

- Ensure the cooling system is properly maintained, including coolant flushes and pressure testing.

- Replace the fan relay as part of a regular maintenance schedule.

Future Trends

The future of radiator fan technology is likely to be driven by the increasing demand for fuel efficiency and reduced emissions. We can expect to see further optimization of electric fan designs, including the use of more efficient motors and advanced control algorithms. Variable-speed fans will become even more prevalent, allowing for even finer control over engine temperature. Integration with hybrid and electric vehicle thermal management systems is another key trend. In electric vehicles, the radiator fan (or fans) plays a crucial role in cooling not only the battery pack but also the power electronics. Furthermore, advancements in materials science may lead to the development of lighter and more durable fan blades, further improving efficiency. Smart cooling systems that anticipate cooling needs based on GPS data, weather forecasts, and driving patterns may also become more common.

Another emerging trend is the use of active grille shutters in conjunction with electric fans. These shutters open and close to control airflow through the radiator, further optimizing aerodynamic efficiency and engine temperature. When cooling demands are low, the shutters close, reducing drag and improving fuel economy. When cooling is needed, the shutters open, allowing air to flow through the radiator and the electric fan to operate.

Conclusion

The radiator fan is not always on in modern vehicles. Sophisticated electric fan systems, controlled by the ECU, provide precise and efficient cooling only when needed. While these systems are more complex than traditional mechanical fans, they offer significant advantages in terms of fuel economy, noise reduction, and temperature control. As the automotive industry continues to evolve, we can expect to see further advancements in radiator fan technology, driven by the relentless pursuit of efficiency and performance. The integration of radiator fans with other thermal management systems, such as active grille shutters and electric vehicle battery cooling, will be crucial in meeting the demands of future vehicles. The ongoing innovation in this area ensures that the radiator fan will remain a critical component of the automotive cooling system for years to come. Understanding the nuances of these systems is crucial for automotive professionals to diagnose and repair them effectively, ensuring optimal vehicle performance and longevity.Regular maintenance is paramount.