My Ac Compressor Wont Turn On

The summer sun is beating down, you hop into your car, crank up the AC, and… nothing. Just warm, stagnant air. A non-functioning AC compressor is a common automotive woe, and understanding why it's refusing to cooperate can save you time, money, and frustration. This article breaks down the potential causes of an unresponsive AC compressor, keeping it simple and accessible for car enthusiasts of all levels.

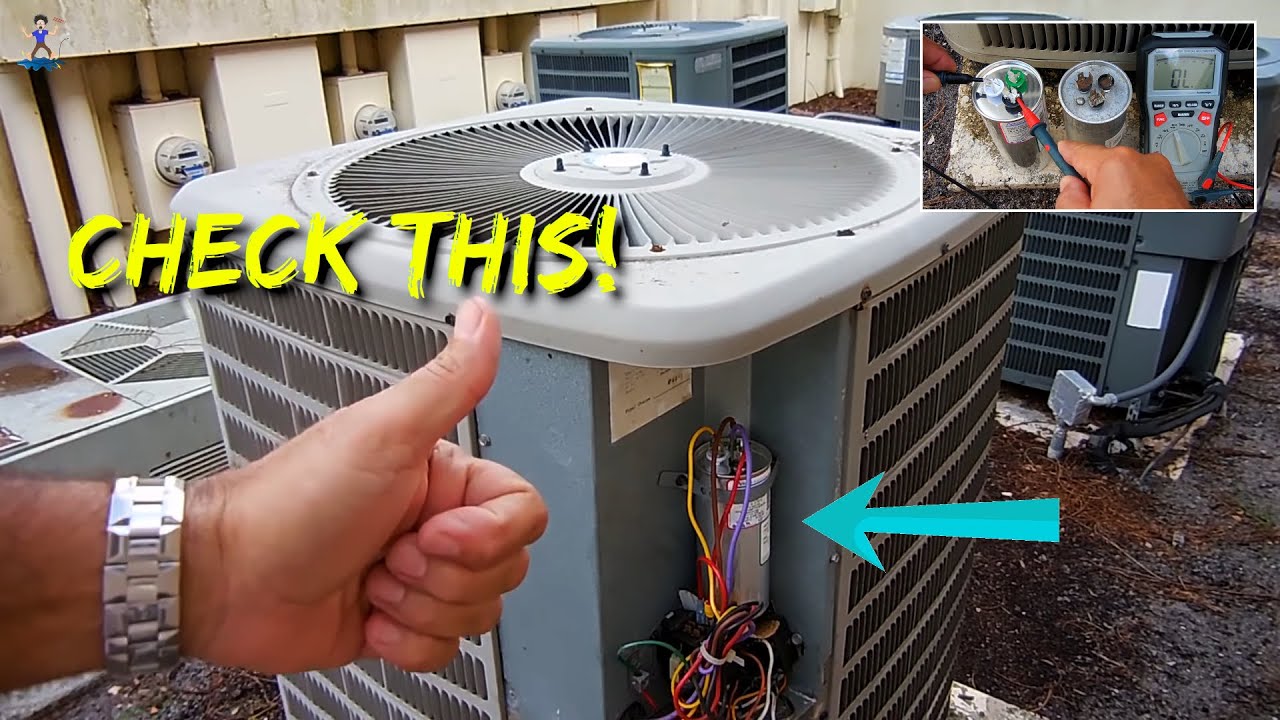

Understanding the AC Compressor: The Heart of Your Cooling System

The AC compressor is the heart of your car's air conditioning system. Its job is to compress refrigerant gas, increasing its pressure and temperature. This high-pressure, high-temperature refrigerant then flows through the condenser (where it releases heat), the expansion valve (where it changes from a high-pressure liquid to a low-pressure gas), and finally the evaporator (where it absorbs heat from the cabin air). The cycle then repeats, providing you with that blissful cool air.

Think of it like this: your AC system is a pump circulating a special liquid. The compressor is the engine that drives that pump. If the engine stops, the circulation stops, and no cooling occurs. The compressor is usually driven by a belt connected to the engine crankshaft. But it doesn't run constantly. It's turned on and off by an electromagnetic clutch.

The Usual Suspects: Why Your AC Compressor Might Not Be Engaging

When your AC compressor isn't turning on, there are several possible culprits. Let's explore the most common ones:

1. Low Refrigerant Level

This is often the first thing to check. Your AC system is a sealed unit, but over time, small leaks can occur, leading to a loss of refrigerant. Many vehicles, like a Honda Civic or a Toyota Camry, have a low-pressure switch that prevents the compressor from engaging when the refrigerant level is too low. This is a safety mechanism to prevent the compressor from running dry and potentially damaging itself.

Why this happens: Refrigerant leaks can occur at various points in the system, including connections, seals, and even small punctures in the condenser or evaporator. Age, vibration, and corrosion can all contribute.

The fix: A qualified technician can identify and repair the leak, then recharge the system with the proper amount of refrigerant. Adding refrigerant without fixing the leak is just a temporary solution.

2. Electrical Issues

The AC compressor clutch is an electromagnetic device. When the AC is switched on, a signal is sent to the clutch, which energizes an electromagnet, pulling the clutch plate towards the compressor pulley. This engages the compressor and allows it to start pumping refrigerant.

Here are some electrical issues that can prevent this from happening:

- Blown Fuse: A blown fuse in the AC circuit is a common problem. Locate the fuse box (usually under the dashboard or in the engine compartment) and check the fuse dedicated to the AC compressor or AC system. Replace the blown fuse with one of the same amperage rating.

- Faulty Relay: A relay is an electrical switch that controls the flow of power to the compressor clutch. A bad relay can prevent the clutch from engaging. You can often test the relay by swapping it with another relay of the same type in the fuse box (for example, the horn relay). If the AC compressor now works, the relay is faulty.

- Wiring Problems: Damaged or corroded wiring can interrupt the electrical signal to the compressor clutch. Inspect the wiring harness for any obvious signs of damage, such as frayed wires, loose connections, or corrosion.

- Faulty Pressure Switches: Besides the low-pressure switch, there's often a high-pressure switch as well. These switches monitor the refrigerant pressure and prevent the compressor from running if the pressure is too high or too low. A faulty pressure switch can send incorrect signals to the control system, preventing the compressor from engaging.

Example: Imagine a Ford F-150 with a damaged wire connecting the AC relay to the compressor clutch. The relay might be working fine, but the signal can't reach the clutch, preventing it from engaging.

The fix: Electrical problems often require a multimeter and some electrical troubleshooting skills. If you're not comfortable working with electrical systems, it's best to consult a qualified mechanic.

3. Compressor Clutch Issues

The compressor clutch itself can fail. Here are some possibilities:

- Worn Clutch Plate: Over time, the clutch plate can wear down, reducing its ability to engage with the pulley. This can result in intermittent engagement or complete failure.

- Failed Electromagnet: The electromagnet that pulls the clutch plate in can fail due to overheating or electrical damage.

- Excessive Air Gap: The air gap between the clutch plate and the pulley needs to be within a specific range. If the gap is too large, the electromagnet might not be strong enough to pull the clutch plate in. This can happen due to wear or improper adjustment.

Example: On an older Chevrolet Silverado, the compressor clutch might have a very large air gap after years of use and vibration. This can prevent the electromagnet from engaging the clutch, especially on hot days when components expand.

The fix: Depending on the severity of the problem, you might be able to adjust the air gap or replace the clutch plate. However, in many cases, it's more cost-effective to replace the entire AC compressor assembly.

4. Problems with the AC Control System

In modern vehicles, the AC system is often controlled by the vehicle's computer (ECU/PCM). The ECU receives signals from various sensors (temperature sensors, pressure switches, etc.) and uses this information to control the AC compressor. A problem with the AC control system can prevent the compressor from engaging, even if all the other components are working properly.

Examples:

"A faulty cabin temperature sensor in a BMW 3 Series could send an incorrect signal to the ECU, causing it to disable the AC compressor."

"A software glitch in the ECU of a Nissan Altima could prevent the AC compressor from receiving the 'on' signal."

The fix: Diagnosing AC control system problems often requires specialized diagnostic tools and a thorough understanding of the vehicle's electrical system. A mechanic can use a scan tool to read diagnostic trouble codes (DTCs) and identify any issues with the control system. Sometimes, a software update can resolve the problem.

5. A seized Compressor

This is the worst-case scenario. If the compressor seizes, it will not turn, and the belt will likely squeal or even break. A seized compressor often occurs due to internal damage, such as worn bearings or a lack of lubrication. Trying to force a seized compressor to run can cause further damage to the engine and other components.

The fix: A seized compressor needs to be replaced. In addition, the entire AC system should be flushed to remove any debris that might have been generated by the failing compressor. The receiver drier should also be replaced, and the system should be properly evacuated and recharged with refrigerant.

Practical Takeaways: Diagnosing and Addressing the Issue

Here are some practical steps you can take to diagnose and potentially address the issue of a non-functional AC compressor:

- Start with the Basics: Check the AC fuse and relay. A blown fuse is a simple fix. Try swapping the AC relay with another relay to see if that resolves the problem.

- Listen Carefully: When you turn on the AC, listen for a click sound coming from the compressor. This indicates that the clutch is attempting to engage. If you don't hear a click, the problem is likely electrical or related to the clutch itself.

- Visual Inspection: Inspect the wiring harness for any obvious signs of damage, such as frayed wires, loose connections, or corrosion.

- Check the Refrigerant Level (Carefully!): Some vehicles have a sight glass on the refrigerant line. If you see bubbles in the sight glass when the AC is running, it could indicate low refrigerant. Caution: Working with refrigerant can be dangerous. If you're not comfortable handling refrigerant, it's best to leave this to a qualified technician.

- Consider Professional Help: If you've checked the basics and the AC compressor still isn't working, it's time to consult a qualified mechanic. They have the tools and expertise to diagnose more complex problems and perform the necessary repairs.

Remember, diagnosing AC problems can be complex. While some issues, like a blown fuse, are easy to fix, others require specialized knowledge and equipment. Don't hesitate to seek professional help to avoid further damage to your vehicle.

By understanding the components of your AC system and the potential causes of a non-functional compressor, you can be better informed when discussing the problem with your mechanic and make more informed decisions about repairs.