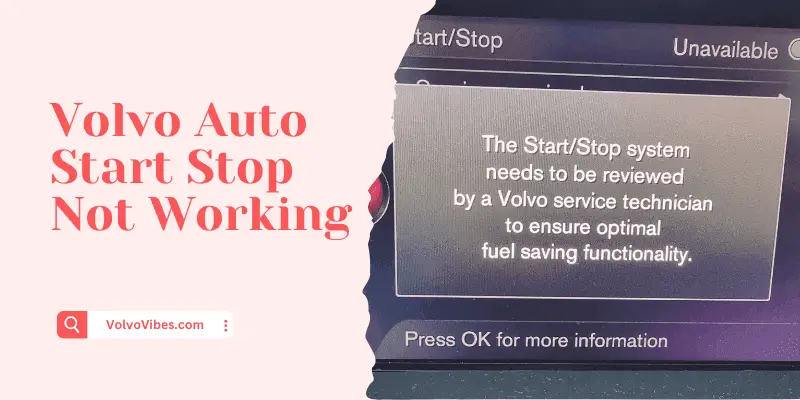

My Auto Start Stopped Working

The frustration of a non-functional auto-start system is a common experience for modern automotive professionals. While seemingly a convenience feature, the auto-start system, also known as idle stop-start (ISS), represents a significant engineering effort aimed at fuel economy and emissions reduction. Diagnosing and resolving issues with these systems requires a thorough understanding of their components, operating principles, and the complex interplay of various vehicle systems.

Understanding Auto-Start Systems

Auto-start systems are designed to automatically shut off the engine when the vehicle comes to a complete stop, typically at traffic lights or in heavy congestion. The engine restarts automatically when the driver releases the brake pedal or depresses the accelerator. This process, while seemingly simple, involves a sophisticated network of sensors, actuators, and control algorithms.

Key Components and Technical Specifications

Several critical components contribute to the reliable operation of an auto-start system:

- Enhanced Starter Motor: Unlike conventional starter motors, those used in auto-start systems are designed for significantly higher cycle counts. This necessitates more robust components, including stronger solenoids, improved brushes, and enhanced lubrication. Technical specifications often cite a life expectancy of 300,000+ starts, compared to a typical starter's 30,000-50,000 starts.

- Reinforced Battery: Auto-start systems demand a battery capable of handling frequent discharge and recharge cycles. Enhanced Flooded Batteries (EFB) and Absorbent Glass Mat (AGM) batteries are common choices, offering superior deep-cycle performance and faster recharge rates compared to standard lead-acid batteries. Internal resistance is a critical parameter, with lower values indicating better performance under high-current conditions.

- Crankshaft Position Sensor (CKP) and Camshaft Position Sensor (CMP): These sensors provide critical engine position data to the Engine Control Unit (ECU), ensuring rapid and precise engine restart. Accuracy and reliability of these sensors are paramount.

- Brake Pressure Sensor: Monitors brake pedal position and pressure, triggering the engine restart when the driver releases the brake.

- Vehicle Speed Sensor (VSS): Confirms that the vehicle is at a complete stop before initiating engine shutdown.

- Engine Control Unit (ECU): The brain of the system, the ECU monitors all relevant sensor inputs and controls the engine shutdown and restart processes. It incorporates sophisticated algorithms to optimize fuel efficiency and minimize driver inconvenience.

- Battery Management System (BMS): Monitors the battery's state of charge (SOC), state of health (SOH), and temperature, preventing the auto-start system from operating under conditions that could damage the battery.

Engineering Choices and Trade-offs

The design of auto-start systems involves several engineering trade-offs. For example, choosing between an EFB and an AGM battery involves balancing cost, performance, and lifespan. AGM batteries offer superior performance and lifespan but are typically more expensive. Similarly, the design of the enhanced starter motor must balance durability, weight, and cost. The ECU programming must also consider factors such as engine temperature, ambient temperature, and vehicle load to ensure smooth and reliable operation.

Troubleshooting Auto-Start System Failures

When an auto-start system fails, the diagnostic process involves systematically checking each component and its associated circuitry. A scan tool is essential for retrieving diagnostic trouble codes (DTCs) that can provide valuable clues about the nature of the problem. Common DTCs relate to battery voltage, starter motor performance, sensor failures, and ECU malfunctions.

Common Causes and Solutions

- Low Battery Voltage: This is the most common cause of auto-start failure. The BMS will disable the system if the battery voltage is below a certain threshold (typically around 12V). Solution: Charge or replace the battery.

- Faulty Battery Management System (BMS): A malfunctioning BMS can provide incorrect battery status information to the ECU, preventing the auto-start system from operating. Solution: Diagnose and repair or replace the BMS.

- Failed Starter Motor: A worn or damaged starter motor may not be able to restart the engine quickly enough, leading to system failure. Solution: Replace the starter motor.

- Sensor Malfunctions: A faulty CKP, CMP, brake pressure sensor, or VSS can prevent the system from operating correctly. Solution: Diagnose and replace the faulty sensor.

- ECU Malfunction: In rare cases, the ECU itself may be faulty. Solution: Diagnose and replace the ECU. This is often the most expensive and complex repair.

- Software Issues: Outdated or corrupted ECU software can also cause problems. Solution: Update the ECU software to the latest version.

- System Inhibitors: Auto-start is often disabled under certain conditions, such as when the air conditioning is running at full blast, the engine is not at operating temperature, or the vehicle is on a steep incline. It's crucial to verify that none of these inhibitors are active before beginning more invasive diagnostics.

Diagnostic Tools and Techniques

Effective diagnosis requires a combination of visual inspection, electrical testing, and scan tool diagnostics. Key tools include:

- Multimeter: For measuring voltage, current, and resistance in electrical circuits.

- Scan Tool: For retrieving DTCs, monitoring sensor data, and performing actuator tests.

- Battery Tester: For assessing battery health and capacity.

- Oscilloscope: For analyzing sensor signals and identifying intermittent faults.

Alternatives to Auto-Start Systems

While auto-start is a prevalent technology, alternative approaches to improving fuel economy exist. These include:

- Hybrid Electric Vehicles (HEVs): HEVs use an electric motor to assist the internal combustion engine, reducing fuel consumption and emissions. They offer more significant fuel savings than auto-start systems.

- Mild Hybrid Systems (MHEVs): MHEVs use a small electric motor to provide regenerative braking and assist the engine during acceleration. They offer a balance between fuel economy and cost.

- Plug-in Hybrid Electric Vehicles (PHEVs): PHEVs have a larger battery pack than HEVs and can be plugged in to recharge. They can travel a significant distance on electric power alone, further reducing fuel consumption.

- Electric Vehicles (EVs): EVs eliminate the need for an internal combustion engine altogether, resulting in zero tailpipe emissions.

Pros and Cons of Auto-Start Compared to Alternatives

| Feature | Auto-Start | HEV/MHEV | PHEV/EV |

|---|---|---|---|

| Fuel Economy Improvement | Moderate (3-10%) | Significant (20-50%) | Very High (50%+) |

| Cost | Low (relatively inexpensive to implement) | Moderate (higher initial cost) | High (significantly higher initial cost) |

| Complexity | Moderate | High | Very High |

| Maintenance | Increased wear on starter and battery | More complex powertrain | Potentially lower maintenance (EVs) |

| Emissions Reduction | Moderate | Significant | Very High (EVs: Zero Tailpipe) |

Reliability and Maintenance

The reliability of auto-start systems has improved over time, but certain components, particularly the starter motor and battery, are still subject to increased wear and tear. Regular maintenance is crucial to ensure long-term reliability.

Maintenance Tips

- Battery Maintenance: Regularly check the battery voltage and condition. Use a battery maintainer during periods of inactivity.

- Starter Motor Inspection: Inspect the starter motor for signs of wear or damage. Listen for unusual noises during engine starting.

- Software Updates: Keep the ECU software up to date.

- Follow Manufacturer Recommendations: Adhere to the manufacturer's recommended maintenance schedule for the auto-start system.

Future Trends

The future of auto-start systems is intertwined with the broader trends in the automotive industry. As vehicles become increasingly electrified, the role of auto-start systems may diminish. However, they are likely to remain a feature on many internal combustion engine vehicles for the foreseeable future.

- Integration with Advanced Driver-Assistance Systems (ADAS): Future auto-start systems may be integrated with ADAS features such as adaptive cruise control and lane keeping assist, further optimizing fuel efficiency and reducing driver workload.

- Improved Battery Technology: Advancements in battery technology, such as solid-state batteries, could lead to more durable and efficient auto-start systems.

- Predictive Auto-Start: Systems that use GPS data and traffic information to predict when the engine should be shut off and restarted could further improve fuel economy.

Conclusion: A Forward-Looking Note

The automotive industry is undergoing a period of unprecedented transformation, driven by the need to reduce emissions and improve fuel efficiency. While auto-start systems represent a relatively small step in this direction, they highlight the ingenuity and complexity of modern automotive engineering. Automotive professionals must stay abreast of these technological advancements to effectively diagnose, repair, and maintain the vehicles of the future. The shift toward electrification presents both challenges and opportunities, requiring a continuous commitment to learning and adaptation.