New Engine Break In Procedure

The allure of a brand new engine is undeniable. The promise of untapped potential, unblemished performance, and the distinct scent of fresh components. But unlocking that potential isn't as simple as turning the key and flooring the accelerator. The engine break-in procedure, often overlooked or misunderstood, is a critical process that dictates the long-term health, performance, and reliability of your new powerplant. This article dives deep into the modern engine break-in, debunking myths and providing practical guidance for enthusiasts, owners, and professionals alike.

The Evolution of Engine Break-In: From Myth to Science

Historically, engine break-in procedures were far more demanding than they are today. Early engines, built with looser tolerances and less sophisticated metallurgy, required extensive and often tedious break-in periods. Think of the old adage about changing the oil after the first 50 miles – that was a relic from a bygone era. These stringent requirements were necessary to allow the mating surfaces of components like piston rings and cylinder walls to properly seat and create a good seal.

Modern manufacturing techniques, including CNC machining, advanced honing processes, and tighter quality control, have significantly reduced the need for such rigorous break-in periods. Engine tolerances are now measured in microns, and many components are pre-stressed or surface-treated to enhance wear resistance. However, this doesn't mean break-in is obsolete. It simply means the process has evolved.

While specific recommendations vary between manufacturers, the underlying principles remain the same: gradually introduce the engine to increasing loads and RPMs, allowing components to "learn" to work together under stress. This controlled introduction helps to ensure proper seating of the piston rings, smooth out any microscopic imperfections, and establish optimal lubrication patterns.

Understanding the "Why" Behind the Break-In

The primary goal of engine break-in is to achieve optimal piston ring seal. Piston rings are responsible for sealing the combustion chamber, preventing blow-by (leakage of combustion gases past the rings), and controlling oil consumption. In a new engine, the ring faces are relatively sharp and the cylinder walls have a distinct honing pattern. The break-in process involves the rings wearing down slightly, conforming to the cylinder wall's surface and creating a tight, consistent seal.

Beyond piston rings, other components also benefit from careful break-in. Bearing surfaces, such as those in the connecting rods and crankshaft, need to develop a thin, consistent oil film. Valve train components, including the camshaft, lifters, and valve seats, need to mate properly to ensure efficient valve operation and prevent premature wear. All of these processes contribute to improved engine efficiency, reduced oil consumption, and extended engine life.

The Modern Break-In Procedure: A Practical Guide

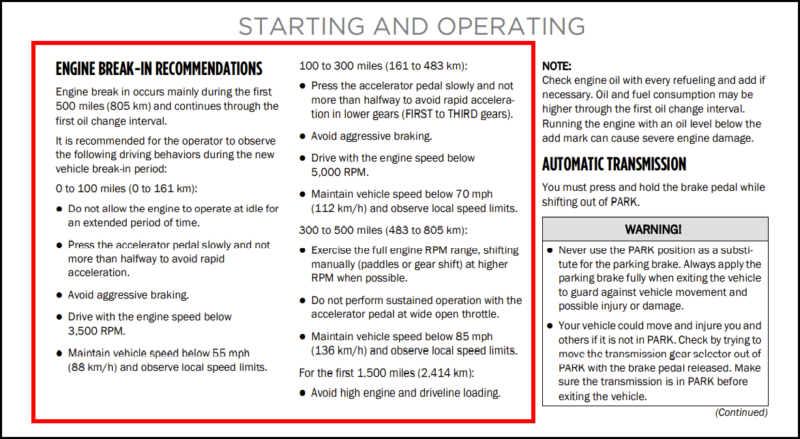

Consult your vehicle's owner's manual – this is the golden rule. Manufacturers spend considerable time and resources developing specific break-in recommendations for each engine. Adhering to these guidelines is crucial for maintaining your warranty and maximizing engine longevity.

That being said, here are some general guidelines that apply to most modern engines:

The First 500 Miles: Gentle Introduction

- Avoid High RPMs: Keep engine speeds below 3,000 RPM (or the manufacturer's specified limit) for the first few hundred miles. This prevents excessive stress on the moving parts.

- Vary Engine Speed: Resist the temptation to cruise at a constant speed for extended periods. Varying the engine speed helps the rings to seat properly across a wider range of operating conditions.

- Avoid Full Throttle: Refrain from aggressive acceleration or "pedal to the metal" moments. Gradual acceleration is key.

- Don't Lug the Engine: Avoid operating the engine at too low of an RPM in too high of a gear. This puts excessive strain on the connecting rods and bearings.

- Check Fluid Levels: Regularly monitor engine oil, coolant, and other fluid levels. New engines may consume slightly more oil during the break-in period.

The Next 500-1000 Miles: Increasing the Load

- Gradually Increase RPMs: As you approach 1,000 miles, you can gradually increase the engine's operating range, occasionally allowing it to reach higher RPMs for short periods.

- Continue Varying Speed: Maintain the practice of varying engine speed and avoiding prolonged cruising at a constant pace.

- Moderate Acceleration: You can now apply slightly more aggressive acceleration, but still avoid full-throttle bursts.

First Oil Change: A Crucial Step

Most manufacturers recommend performing the first oil change sooner than the normal interval. This is to remove any metallic particles or other contaminants that may have accumulated during the break-in process. Consult your owner's manual for the recommended interval, but typically this falls between 500 and 1,500 miles. Use the recommended oil type and filter specified by the manufacturer. This is not the time to cheap out. Using a high-quality oil is essential.

Debunking Common Myths

Several myths surround engine break-in, often fueled by anecdotal evidence or outdated information. Let's address some of the most common ones:

- Myth: "Drive it like you stole it" is the best way to break in an engine. Reality: This aggressive approach can damage the engine and prevent proper ring seating. Controlled and gradual loading is far more effective.

- Myth: Synthetic oil should be avoided during break-in. Reality: This used to be true, as some early synthetic oils were believed to inhibit ring seating due to their superior lubricating properties. However, modern synthetic oils are formulated to be compatible with engine break-in. Check your owner's manual for specific recommendations. Many modern cars ship with synthetic oil from the factory.

- Myth: Break-in is unnecessary with modern engines. Reality: While modern engines are built to tighter tolerances, a break-in period is still recommended to ensure optimal performance and longevity.

- Myth: Aftermarket engine additives are beneficial during break-in. Reality: Most additives are unnecessary and can even be detrimental. Stick to the manufacturer's recommended oil type and avoid adding any aftermarket supplements.

The Professional's Perspective

For mechanics and workshop professionals, understanding the engine break-in process is essential for providing informed advice to customers and performing proper maintenance. When working on a newly rebuilt or crate engine, it's crucial to follow the manufacturer's specific break-in recommendations. This may involve using a dyno to simulate various driving conditions and monitor engine performance.

Furthermore, educating customers about the importance of break-in can help prevent premature engine failures and costly repairs. Explain the rationale behind the recommended procedures and emphasize the long-term benefits of following them. A little bit of knowledge can go a long way.

Consequences of Neglecting Break-In

Ignoring the engine break-in procedure can lead to a variety of problems, including:

- Increased Oil Consumption: Improper ring seating can result in excessive oil consumption.

- Reduced Power and Performance: Poor ring seal can lead to blow-by, reducing engine power and efficiency.

- Premature Engine Wear: Excessive stress on engine components during the initial miles can accelerate wear and shorten engine life.

- Increased Risk of Engine Failure: In severe cases, neglecting break-in can lead to catastrophic engine failure.

Real-World Examples and Considerations

Consider the Subaru WRX, a popular performance car known for its robust but sometimes temperamental engine. Subaru explicitly outlines a break-in procedure in their owner's manuals, emphasizing varying engine speed and avoiding sustained high RPMs. Owners who disregard these recommendations often report higher rates of oil consumption and engine-related issues later in the vehicle's life. On the other hand, those who adhere to the break-in procedure tend to experience fewer problems and longer engine life.

Another example is the Ford Mustang GT. While Ford's break-in recommendations may be less stringent than Subaru's, they still emphasize the importance of gradual loading and varying engine speed. Skipping the break-in period could affect the long-term performance and reliability of the vehicle's Coyote V8 engine.

Ultimately, the engine break-in procedure is an investment in the long-term health and performance of your vehicle. While it may seem tedious or inconvenient, following the manufacturer's recommendations will help you unlock the full potential of your new engine and enjoy years of reliable driving.

Therefore, while modern engines are built to incredibly tight tolerances, the break-in period still matters. Don't just "fire and forget," follow the guidelines and give your engine the best possible start in life.